Steel Division

Excellent corrosion protection

A striking feature of corrender® is the high-performance corrosion protection as opposed to conventionally galvanized steel strip. The significantly higher protective effect of corrender® results in a thinner metallic coating of zinc.

Excellent workability

corrender® also convinces through increased efficiency in processing and leads to a significant reduction in production costs. The potential can be utilized more effectively than ever before: Low zinc abrasion, excellent deep-drawing properties, low friction, the associated low oil consumption and very high profiling capacity all result in excellent processing properties.

High-performance alternative

The superior corrosion protection of corrender® opens up several options: new markets that require better protection with the same thickness or significant savings with the same protection.

The excellent corrosion protection of zinc-magnesium coatings is well known. corrender® takes it one step further. corrender® is a perfectly coordinated coating that is superior to conventional zinc-magnesium coatings and provides a higher level of corrosion protection.

voestalpine offers broad process expertise in production. In collaboration with process specialists, corrender® was developed with a view to maximizing efficiency. The result is a product with the lowest zinc abrasion, excellent deep-drawing properties and maximum profiling.

voestalpine is regarded as a pioneer in the production of zinc-magnesium-aluminum alloys on the European market. This success story began in 2007 with the serial supply of corrender®. Numerous laboratory tests, worldwide exposure testing, large-scale plant trials and customer applications, experts at voestalpine have established comprehensive product understanding and specialist knowledge.

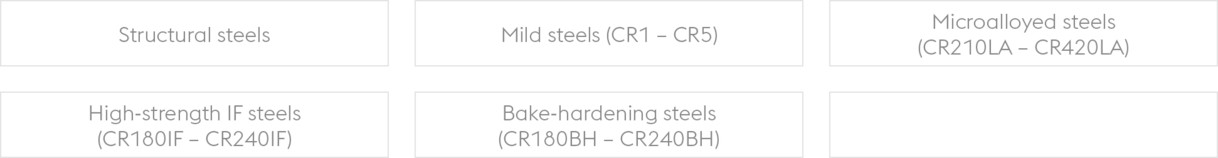

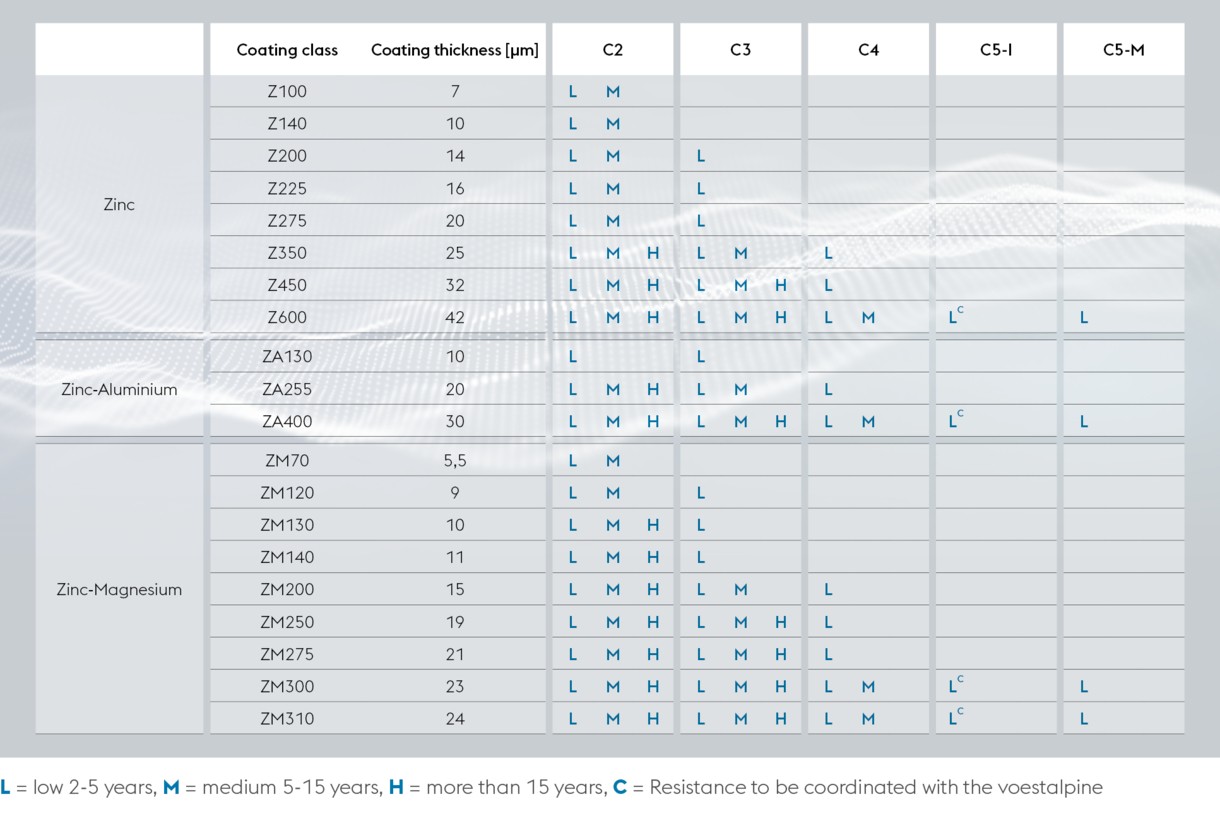

corrender® is available from ZM 70 g/m² to 310 g/m² and in all conventional steel grades used in the automotive industry. Products range from mild steels and bake-hardening grades to high-strength and ultra-high-strength steels.

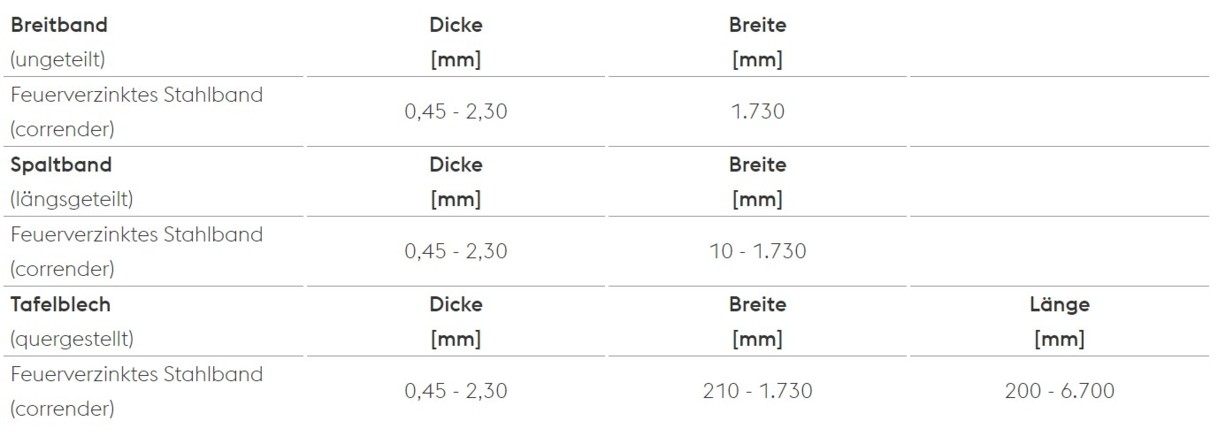

Indicated values are standard references. Limitations are possible depending on thickness.

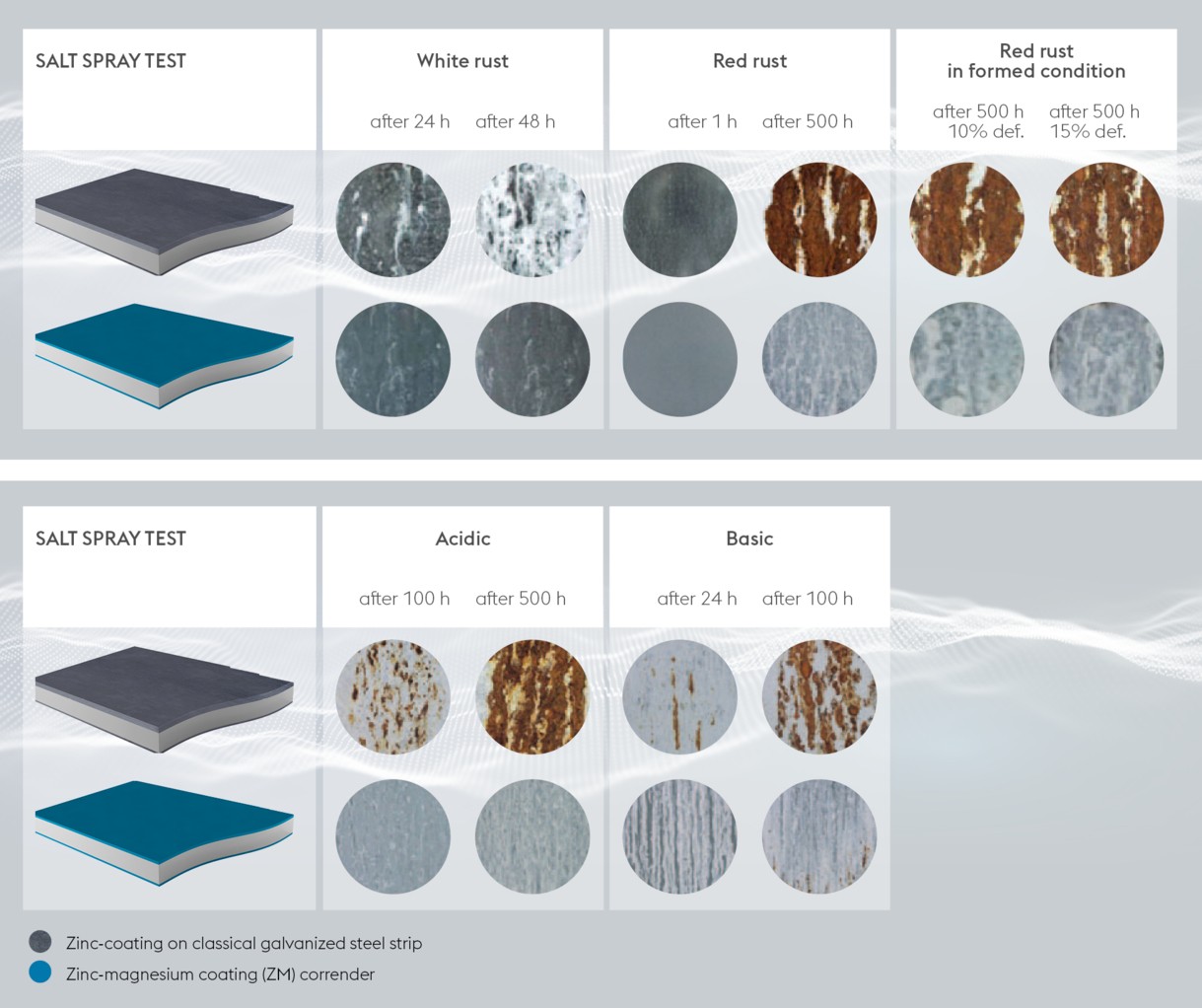

The corrosion protection of corrender® is significantly higher than that of conventionally galvanized steel strip, even in formed condition.

In heavily acidic environments and under alkaline stress, corrender® also exhibits significantly increased protection.

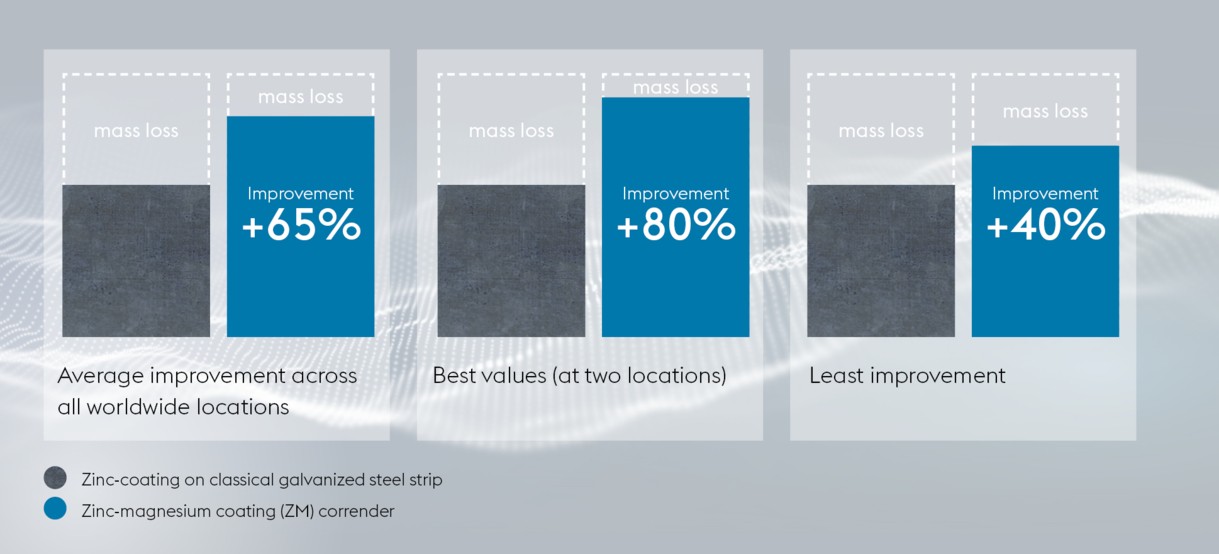

In order to demonstrate the performance of corrender® under natural conditions, corrender® samples and samples of conventionally galvanized steel were exposed in 14 different locations worldwide. These exposure tests were conducted in collaboration with the French Corrosion Institute to ensure that differing temperatures, precipitation volumes, humidity and pollution levels (SO2 and NO2) and distances to the ocean were taken into due consideration.

After one year, corrender® loses a significantly smaller amount of mass at each of the worldwide locations and thus higher protection against corrosion than conventionally galvanized steel strip. An average improvement of 65 % was determined across all the locations, whereas the protection level was increased by more than 80% at some of the places. The increased level of protection was not lower than 40% at any of the locations.

During the design of the steel structure, compliance with all relevant instructions pertaining to protecting the structure from corrosion is mandatory (see Reference Sheet 121:2003 of the Steel Information Center, Corrosion Protection Systems for Sheet Steel Components and other instructions). Standing water, dripping moisture, impurities and contact corrosion must be avoided through composite construction.

Please note that no warranty or guarantee against corrosion damage can be derived from this table. Users shall be responsible for the planning and design of their steel structures (and corrosion protection).