Steel Division

The power generation sector demands reliable quality in materials for applications from highest to lowest temperatures. Security of supply is a prerequisite for power plants in order to guarantee unrestricted electrical supply. Our expertise is focused on well-known plant manufacturers in the energy sector, and we supply our castings worldwide.

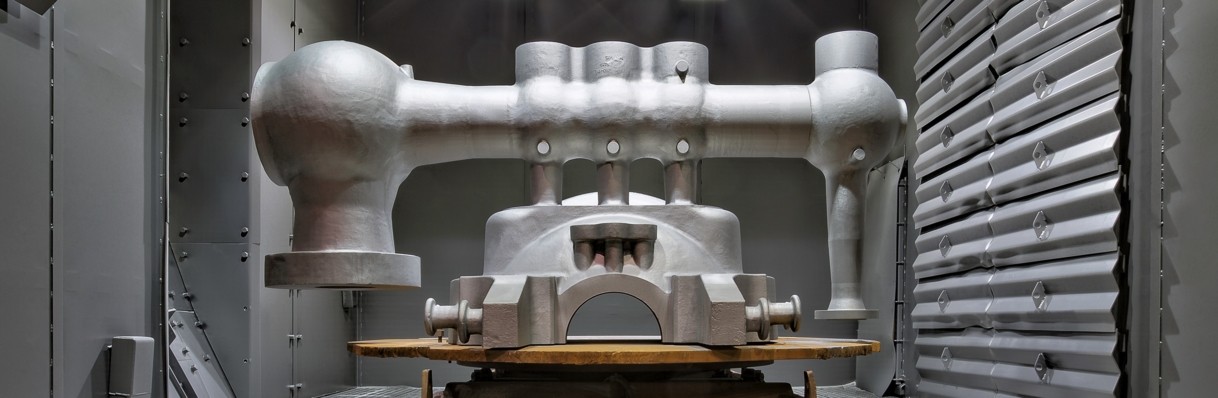

We are a trusted partner for all renowned turbine manufacturers thanks to our many years of experience and top-notch metallurgical equipment. We produce parts for Francis, Kaplan, and Pelton turbines, as well as castings for sophisticated applications such as pumped storage hydro (PSH). Take a closer look at our portfolio.

Impeller (Monoblock / Bi-Block), Discharge Rings, Francis Blades, Crown & Band, Kaplan Blades, Hub, Wicket Gates / Guide Vanes, Blade Levers, Crosshead, Pelton Buckets, Propeller and more miscellaneous components

Our ready-to-install steel castings are in high demand for gas-driven turbines with specific customer requirements. We are prepared to assist our customers in the design of steel castings for new gas turbine types. Our goal is to ensure the best overall solution for material, machining and assembly.

Turbine and compressor housings, Vane supports, Diffusers, Inner housings, Bearing and seal housings, Seal housings and more miscellaneous components

Full steam ahead! CO2 reduction as a contribution to environmental protection is one of our top priorities, which is why the highest possible efficiencies are required in steam turbines. We are the world's leading supplier and developer of high-temperature steels with operating temperatures up to 630-650 °C or nickel-based alloyed materials > 700 °C.

The focus is on the highest safety requirements and at the same time the requirement for large and extra-heavy weights of the steel castings. . Our highly qualified personnel and comprehensive production facilities meet every requirement of our customers’ world-famous nuclear housings.

Outer and inner housings, Valve bodies and covers, Blade carriers and more miscellaneous components

Our many years of experience have made us very successful in major projects completed in the offshore wind sector. Our core expertise focuses on the development of individual solutions in collaboration with our customers.