Steel Division

voestalpine Grobblech GmbH is one of the world’s leading producers of linepipe plates. More than two million tons of sour-gas resistant linepipe plates and very tough linepipe plates for thick-walled deep-sea lines testify to the success of our high-quality products. As a partner to renowned pipe makers we provide outstanding product quality, reliable service and flexibility.

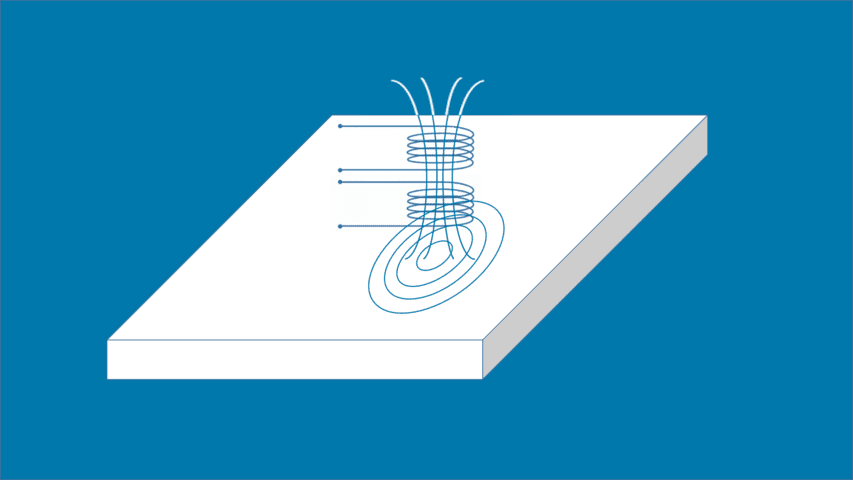

We at voestalpine demonstrate the absence of local hard zones (LHZ) by eddy current method and hold the biggest track record of LSAW material in operation. Supported by industry’s supreme accuracy and highly automated testing equipment we provide our partners the basis for a cost efficient project execution in severe sour environments (high H2S).

Extreme pressures in the deep ocean or sour service - Our linepipe plates can stand even the most difficult conditions. Our products are found in depths of up to 3,000 meters meters below the sea surface and also in the form of sour-gas-resistant linepipes.

Our linepipe plates provide excellent toughness at low temperatures, best weldability and high uniform elongation for strain-based design. Available up to 18.7 m in length and with a weight up to 20 tons per plate.

Roll-bonded clad plates are used for the manufacturing of clad linepipes. In many cases the mixture of oil, gas and a wide range of chemical elements in riserpipes or linepipes used for the transport of oil and gas formes a highly corrosive environment. Only the highest-quality materials are capable of withstanding this aggressive medium. Our roll-bonded clad linepipe plates with corrosion-resistant cladding meet these highest corrosion requirements.

We are there with land lines up to 48 inches (1,220 mm) in diameter.

We provide excellent toughness at low temperatures and our service is tailored to the individual customer from the time the order is received until the material is loaded for on-time shipment and delivery.