Steel Division

“We are your reliable partner in the supply of steels for pressure vessels, apparatuses and power generation equipment, understand our customers and provide the quality they need” As the world’s only single-source supplier of shell plates, heads and cones in carbon steel and roll-bonded clad plates, we are able to provide optimized workability and lower expense for our customers.

We are a single-source supplier of shell plates, heads and cones made of plain carbon steel, in roll-bonded clad design and for sour service.

Reduce the wall thickness of your componens by using our high-strength CrMo and CrMoV steel und chose your ideal plates dimension up to 200 mm in thickness and 24 tons per plate.

We offer 5%- and 9%-nickel steels according to EN 10028-4 and ASTM 553 in plate thickness range up to 70 mm, width up to 3,800 mm, length up to 12,700 mm and up to 13 tons per single plate.

The revision of API Standard 620 in 2018 has made it possible to use ASTM steel grades A 645 Gr A and Gr B for the construction of ethylene, LPG or LNG tanks. Our state-of-the-art production facilities make it possible for us to manufacture both steel grades A 645 Gr A and Gr B as well as conventional 5% and 9% nickel steels.

Clad plates are the economic alternative to expensive high-alloy and non-clad plates. Roll-bonded clad plates are our answer to corrosion and explosion.

With a cladding capacity of 60,000 tons a year, we are World´s leading producer of roll-bonded clad plates.

We supply steel plates and material expertise for the penstocks of hydro-power stations and provide high-strength heavy plates as fine-grained steels with a minimum yield strength of 700 MPa in TMCP, direct-quenched and tempered or quenched and tempered condition.

In a first-time application of high-strength TMCP steel, special-grade alform plate 700 M of voestalpine was successfully used in the penstock of the Reisseck pumped-storage hydro-power station in Austria.

Offering shell plates, heads and cones from a single source, made of carbon steel and roll-bonded clad plates.

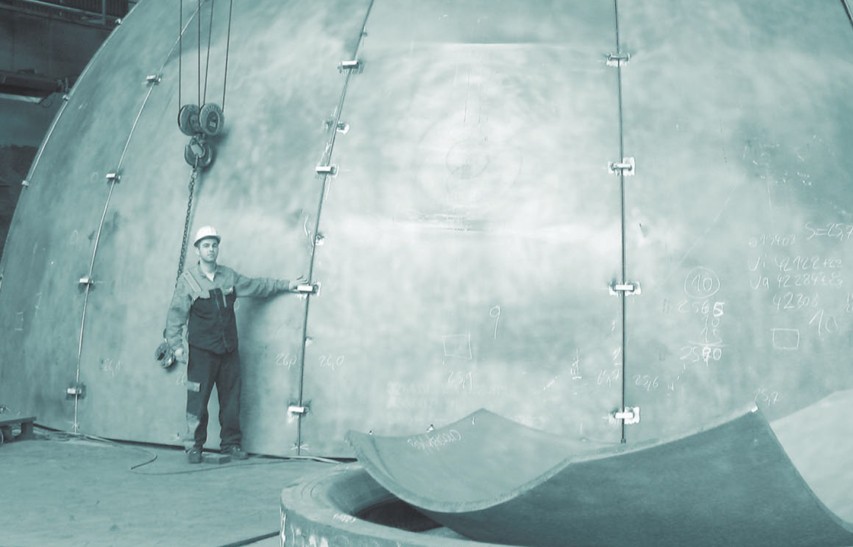

In our own Single-part and multi-part heads and cones, special pressed parts

We manufacture custom-made heads as a single part or welded from multiple parts. Multi-part heads and cones are available in head gauges of up to 160 mm and diameters of up to 14,000 mm.