News

-

Recyclable plastic cable troughs: a preferred and more sustainable alternative for concrete

In a world that is changing every day, with sustainability being one of our top priorities, the expectations are equally high in terms of the reuse of existing resources. We also want to offer the next generation a greener environment. And one way to achieve this goal is by introducing thermohardened material, the likes of fuse boxes and pool balls. It is exactly this recycled material which forms the basis for our recyclable plastic cable troughs! A sustainable substitute for its concrete version. The first recyclable plastic troughs have already successfully been installed in the Dutch rail infrastructure. Meaning that we are another step closer to a more sustainable railway industry.

Read more -

The DeltaSwitch: an ingenious piece of innovation

As the English saying goes: Never change a winning team. But what if you could enhance that team with a small innovation? One of our clients needed a solution to replace the current EKOS-V systems with in the nine 1:9 NP46 turnouts near Amsterdam Westhaven. With just a small adjustment to our DeltaSwitch, we were able to offer our client the perfect solution they were looking for.

Read more -

Our Insulated Rail Joint Repair System; the American Dream!

Defective rail joints can be found all over the world. Even in the United States, IRJs are often found to be the cause of malfunctions in the rail infrastructure. In line with our mission ‘connecting the world of rail’, we supported our sister company and distributor in the USA, voestalpine Railway Systems Nortrak with the sales opportunities for our Insulated Rail Joint Repair System. voestalpine Railway Systems Nortrak then offered New York Transit the solution, so that they can continue to work on a safer and reliable railway.

Read more -

Coating production line re-opened: 360 meters of coated rails

Our renewed coating production line is officially open for business! The world’s longest coated rails can now be produced in Hilversum, the Netherlands. Rail rolling lengths of 120 meters are coated and then connected by two flash butt welds of up to a maximum of 360 meters. The coating line has been completely upgraded for durable operation and improved adhesion. The relocation and its upgrade was a complex project, which included adjusting the hoisting height of our gantry cranes and taking up part of the cable park. Luckily we could count on the patience of our valued customers and tireless efforts of our colleagues. The patience has been rewarded and we are now producing at full speed:

-

DeltaSwitch enhances lifespan of switch blades due to reduction in wear

Turnouts deal with frequent track-train interaction by wheel sets annually. This train-track interaction leads to varying loads on different components inside the turnout, which can cause fatigue, wear or worse. This is undesirable and must be prevented at all times. Fortunately, a solution is now available that prevents such issues: the DeltaSwitch. This lubricant-free switch point roller system not only reduces the wear of the switch blades, it also reduces the wear in the slide plates. And last, but certainly not least, it requires less maintenance and/or adjusting than with other similar lubricant-free switch point roller systems.

-

voestalpine travel tip! 5 impressive must-see railway routes

The European Union has declared 2021 as the ‘European year of the railway’ in order to promote the train as both a save and sustainable transport. And we at voestalpine Track Solutions Netherlands fully agree. After all, travelling by train is the best way to discover the most beautiful locations that cannot be reached by car. Enjoy a bite to eat and a lovely drink while fully enjoying the view during your travels. Now that Summer has finally arrived, we like to share five impressive railway routes within Europe you don’t want to miss:

-

Smart maintenance concepts expand the lifecycle of metro and light rail networks

The population globally is ever growing, especially in the last century. In the Netherlands, for example, we went from 5 million citizens in 1900 to approximately 17 million citizens in 2020. More citizens and a thriving economy resulted in an increasing demand to mobility. Especially in urban areas, where trams and metros are operating 24/7, the tracks experience heavy loads. The demands to comfort and safety are at a consistently high level and noise and dust emissions must be kept to an minimum level. In addition, due to the 24/7 operation, less hours are available for maintenance work, which are often also logistically complex. More load, more wear, but less time for maintenance against high user demands causes rail defects like corrugation and plastic deformation. A complex challenge that we happily make a decisive contribution to in order to resolve this: rail milling by the MG11.

-

Connecting the world of rail with all our welds

Connection. The vital link between two components. Approximately 7.097 km of railways are connected in the Dutch railway infrastructure to offer travelers a safe and reliable way to get to their destination. The connection of rails, however, cannot be done without welds. And rail welds cannot be done without certification in order to guarantee safety and the highest quality. We recently extended our Rail Services portfolio with the flash butt weld certificate for the 400 UHC® HSH® rail quality. From now on, the 400 UHC® HSH® rails can be supplied in ultra-long lengths of up to 360 meters. (Fun fact: UHC stands for the metallurgical steel design based on Ultra High Carbon content, and HSH describes a unique heat treatment technology, so-called Head Special Hardened.)

-

Recap of the RailTech Europe Live with our CEO

2021. The year that is already known as the year of online fairs. The kickoff for the rail infrastructure market related fairs was in March with the RailTech Europe Live. For three full days, visitors were able to follow presentations and workshops, visit online stands, and have personal conversations via the chat option.

-

New name, same brand – voestalpine Railpro is now voestalpine Track Solutions Netherlands B.V.

Our organization has been breathing railway history for many years. However, we are now in full motion towards a future of a safe and available railway infrastructure. From wholesale industry to a total solutions provider. It is our ambition to always remain One Step Ahead.

-

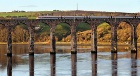

More efficiency in the logistics of rail ballast transport

The transport of rail ballast from quarry towards railway is a complex logistic process. We reached a great milestone in terms of efficiency and sustainability by bringing together several processes in one location in Amsterdam. The port area in the Western part of the city can, in the easiest way possible, directly provide all modalities and facilities for the distribution of the ballast throughout the country.

-

Meet us at this year’s RailTech Europe

On March 30 and 31 and on April 1, 2021, RailTech Europe is the digital meeting place to get acquainted with relevant matches in the railway industry. In these trying times, now more than ever there is a need for coming together and share insights about current developments. It is time to work together and build a resilient, international, and future-proof railway.

-

A greener railway while reducing our environmental impact

A safe and available railway track means exquisite maintenance. And when necessary, renovation or new construction will also take place. Which results in the release of a lot railway materials. Our goal is to decrease the ecological footprint in the rail infrastructure market and thereby contribute to a circular economy. So how can we work together in creating circular railways worldwide?

-

Rubber coating stops deterioration of the rail due to snow residue and road salt

We all enjoyed a beautiful winter’s week. However, what becomes visible underneath the snow and ice when the thaw sets in? Mud and road salt residues. Not the best conditions for the railway infrastructure, particularly for level crossings. Road salt and moisture, in combination with stray currents, bite into the rail, causing the metal to corrode fiercely. This process severely undermines the rail’s quality and increases the risk of premature rail replacement. Apart from hindrance to the train traffic, it is a costly affair for the maintenance contractor.

-

Another successful test with our dust suppressing ballast train in Germany

Twelve wagons with nearly 300 tons of ballast unloaded in less than 30 minutes. The second test with our dust suppressing ballast train (or in Dutch called the SALT) , this time executed in the Hönebach Tunnel nearby Kassel in Germany, was another great success. Since April, 2020, a law amendment has been in force that requires dust-free unloading procedures in tunnels. The dust suppression system has contributed to better and safer unloading techniques within the railway infrastructure in the Netherlands, and is now also a great option for abroad. This wagon type has many advantages, of which the hydraulic valves are just one example. Several parties - among which BG Bau – showed immediate interest in this new solution after a first trial.