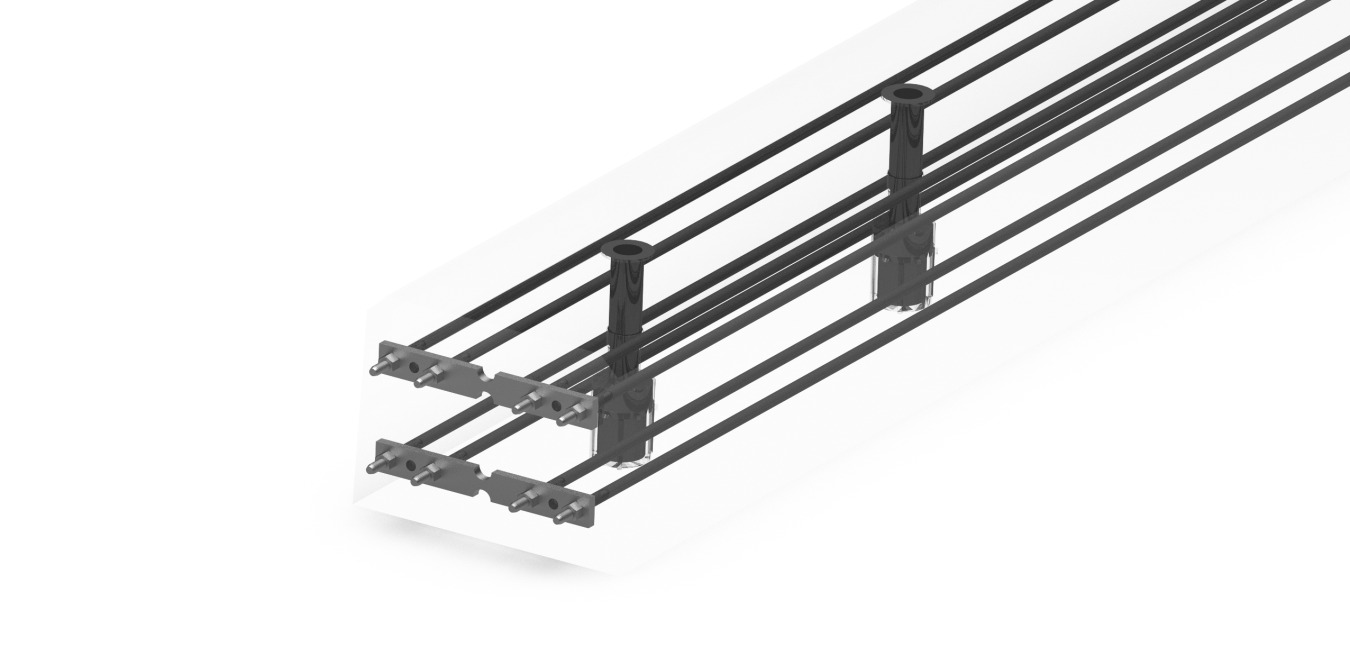

Bearer with end anchoring

The bearer with end anchoring technology is used in turnouts and is designed to meet the requirements of EN 13230-4 including a maximum axle load of 250kN.

The bearer with end anchoring technology is used in turnouts and is designed to meet the requirements of EN 13230-4 including a maximum axle load of 250kN.

The bearer can be provided with different fastenings systems depending on customer requirements. Due to the used long-line manufacturing process, variable bearer lengths, track gauges and fastening positions are easily producible.

The post-tension is made with eight 9,4 mm thick tension wires in plastic pipes and end anchoring plates. Compared to direct bonded prestressed concrete bearers, this technology offers the advantage of a significantly shorter force transmission length. So, the full preload is provided over a much longer distance. This aspect leads to less risk of crack formation (especially longitudinal cracks) and increases the safety against bearer breakage.