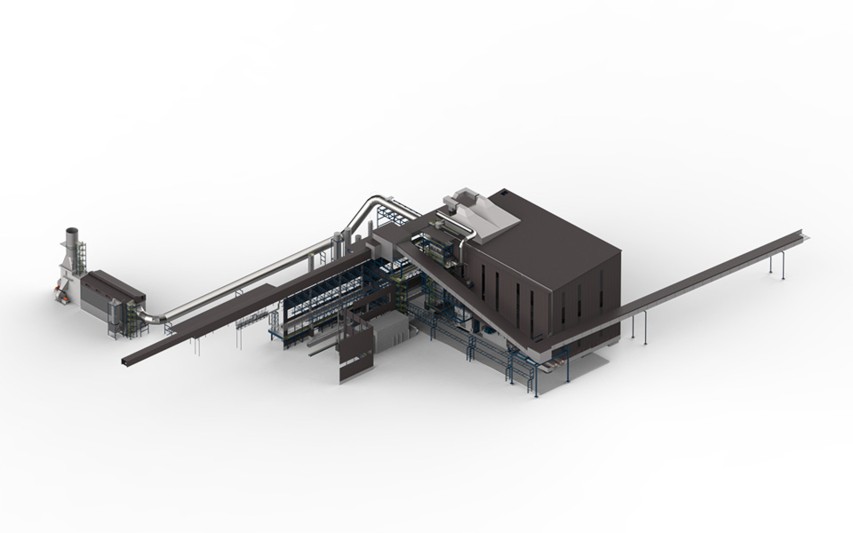

Second Life: 20% energy recovery in the electric arc furnace (EAF)

Scrap, hot-briquetted iron (HBI, porous sponge iron) and hot metal are melted together using electrical energy as well as chemical reactions in coal and gas mixtures. This energy-intensive process yields exhaust gases at very high temperatures. These hot exhaust gases are recovered to generate steam before they are cleaned in the dedusting process.

Heat recovery

The discharge manifold directs the hot exhaust gas directly from the EAF vessel to the heat recovery system through a vacuum generated in the dust collector. The gas flows along heating surfaces and through an evaporator unit, after which it cools to roughly 450 °C. The heat is used in a water-steam system: Saturated steam is produced in a steam drum and is temporarily stored in two large steam tanks before it is channeled into the steam network of the steel works. The temperature of the saturated steam is such that any amount of heat cannot be released without condensation. The steam is used in the power station to generate electricity.

The centerpiece of the system is the waste-heat boiler.

The most important component of the heat recovery system is a water pipe boiler with forced circulation. It is a true heavyweight at a whopping 445 tons. Principle of operation:

- Degassed and preheated feed water is delivered into the feed water tank.

- Feed water pumps bring the boiling water to the required pressure and feed it into the steam drum.

- There it circulates along the heating surfaces of the boiler and evaporates partially before it is fed back into the drum as a mixture of water and steam.

- The steam is separated from the water in the drum. The saturated steam is buffered and fed to the steam network of the steel works.

The system is automated to a high degree. Various control systems ensure stable operation. Steam generation can automatically switch to energy-saving standby mode during longer intervals between melts. Critical production system conditions are avoided by safety systems.

Challenges: compensation, utilization of space, dedusting

One of the major operational challenges is the dynamic melting process. Operation of the electric furnace is cyclical (27–37 minutes of heating followed by a ten-minute interim for discharging and refilling). This irregular operation results in high fluctuations in the generation of steam, and this must be compensated by steam in the tanks. The operating personnel is also challenged by a limited amount of space. The heat recovery system is located very close to the furnace. A large share of the heat recovery boiler is mounted on the side of the bay at a height ranging between +20 and +58 meters. Heat recovery is not the only process that must be carried out. The high dust load in the exhaust gas comprises a significant share of the dust contained in the exhaust gas and must be separated in the dust settling chamber.

Overview of technical data

- Steam-cooled extraction duct:

- Cross section: roughly 5–3 meters

- Length: roughly 107 meters

- Heating surface: 2,975 m² (nearly half the size of a football field)

- Exhaust gas extraction through heat recovery:

- Volumetric flow: roughly 240,000 Nm³/h

- Temperature drop from 1,600 to 450°C.

- Steam production:

- up to 60 tons/hour, depending on EAF operations

- Pressure ratios:

- steam drum: up to 40 bars, corresponding to roughly 252 °C

- Weights of main components, excluding piping/water

- Steam drum: 75 t

- Boiler: 445 t

- Two steam storage tanks, 103 tons each

Conclusion: Recycled energy

As part of the greentec steel project, the heat recovery plant makes an important contribution to sustainable and energy-efficient steel production. It makes optimum use of the high-temperature energy contained in the exhaust gas and feeds it back into the production process. A masterpiece made possible by the technical experts and others under highly challenging conditions.

To greentec steel

The greentec steel project of voestalpine is an ambitious step-by-step plan that makes a valuable contribution to the achievement of the climate goals. As a first step, the voestalpine Group plans to replace two blast furnaces with two electric arc furnaces (EAFs) by the year 2027. The investment volume amounts to roughly 1.5 billion euros.

Carbon emissions can be reduced by up to 30% as early as 2029 by making this switch from the blast furnace to the EAF. This corresponds to a savings of nearly 4 million tons of CO2 per year, amounting to nearly 5% of the carbon emissions in Austria. This makes greentec steel the largest climate protection program in Austria.

The two electric-arc furnaces will enable voestalpine to produce roughly 2.5 million tons of carbon-reduced steel by the year 2027, roughly 1.6 million tons in Linz and 850,000 tons in Donawitz. Learn more about greentec steel here.