Construction of the HBI supply system for greentec steel starts

Construction has started

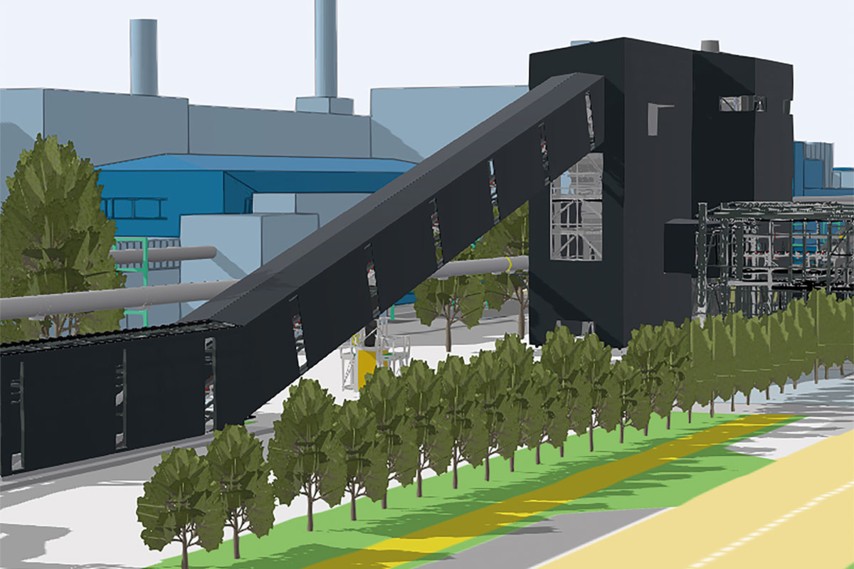

After intensive planning and design activities, construction work on the HBI supply can now be started. The new facility consisting of delivery, screening including sampling and dust removal will be erected in the raw material supply area. The next few months will be concentrated on the civil engineering works. The structural steelwork and conveying technology installation begins in the spring of 2026.

The HBI route

Each year, around 450,000 tonnes of this input material is needed for the first EAF.

Most of the material will come from Texas and will be delivered to Koper in Slovenia by ocean-going ship. From their it will be delivered by train to the elevated railway in Linz where it will be unloaded and transported to the HBI supply system by truck. In the first step, the system removes unwanted parts from the input material and the fines are screened.

The chemical composition of the remaining HBI is analysed in an automated sampling system and it is then fed into the raw material supply. It is further transported in the direction of the EAF on the already completed conveyor belt bridge.

Dust-free environment

A dust extraction system ensures a dust-free environment in the whole facility. The extracted dust and the fines from the screening, as iron-rich material, are fed back into the internal cycle and are reprocessed in the sintering plant.

The valuable input material is therefore retained in-house.

About greentec steel

With greentec steel, voestalpine has an ambitious and viable phased plan in order to make its contribution to achieving the climate goals. In the first step, the Group plans to replace two blast furnaces with two electric arc furnaces (EAFs) from 2027. This involves an investment of around 1.5 billion euros.

With the partial changeover from the blast furnace to the electric steel route, by 2029, CO2 emissions will have been reduced by around 30 %. This equals a saving of almost 4 million metric tons of CO2 per year – or almost 5 % of Austria's CO2 emissions. greentec steel is thus the largest climate protection program in Austria.

With the two electric arc furnaces, from 2027, voestalpine can produce approx. 2.5 million metric tonnes of Co2-reduced steel annually, of which, 1.6 million metric tonnes in Linz and 850,000 metric tonnes in Donawitz. Find out more about greentec steel here.