The premium substrate for durable surfaces

Enameled steels made by voestalpine perfectly combine functionality and design. They enable secure enamel adhesion, the highest processing quality and can be used flexibly in any common enameling process. Whether at home, in sanitary products or in the industry, our steels create the basis for durable, high-quality surfaces that are inspiring.

Your benefits at a glance

Convincingly versatile: applications featuring enameled steel

Enameled steel is a material that combines strength, aesthetics and durability in perfect harmony. Its unique combination of durability, longevity and ease of care makes it the ideal choice in many areas of everyday life – from bathrooms and kitchens to industrial applications.

Sanitary systems: long-lasting elegance for bathrooms and wellness areas

Enameled steels stand for quality that you can see and feel in the sanitary industry. Whether for bathtubs, shower trays or boilers, their non-porous surface is hygienic, easy to clean and appealing. Their surface remains resistant and flawless even in daily contact with water, soaps and detergents.

Household appliances: robust, hygienic and tasteful

With its durability and comfort in everyday life, enameled steel is impressive in the kitchen. In ovens and on stoves or pots, it ensures heat-resistant, easy-to-clean surfaces that do not take on any odor or taste. This results in long-lasting quality as well as personal enjoyment and safety in everyday cooking.

Industrial systems: reliability under extreme conditions

Durable, safe and economical: In industrial applications such as facade cladding, heat exchangers, silos and road signs, enameled steel shows its true strength. Corrosion resistance, weather resistance and mechanical strength make it the ideal material for demanding applications.

A high-tech product portfolio to meet every demand

voestalpine offers a wide range of hot-rolled and cold-rolled enameled steels that are ideally suited to wet and powder processes with excellent coating adhesion and outstanding cold forming properties. Depending on the requirements, surfaces can be enameled on one side or both. The result is long-lasting, high-quality products that withstand even the most adverse conditions.

| EN10209 | Special voestalpine grade | Thickness | Width | |

| Cold-rolled enameling steels | DC01EK | 0.5 – 1.6 mm | 900 – 1,600 mm | |

| DC04EK | ||||

| DC06EK | ||||

| DC07EK | ||||

| DC03EK TiVac | ||||

| DC04EK TiVac | ||||

Hot-rolled enameling steels | DD11CCE | 1.8 – 20 mm | 900 – 1,750 mm | |

| DD15CCE | ||||

| S240CCE | ||||

| S355CCE | ||||

| S380CCE | ||||

Please find all the information on mechanical properties and chemical compositions here:

Data sheet enameling steels PDF1.41 MBeng-GB

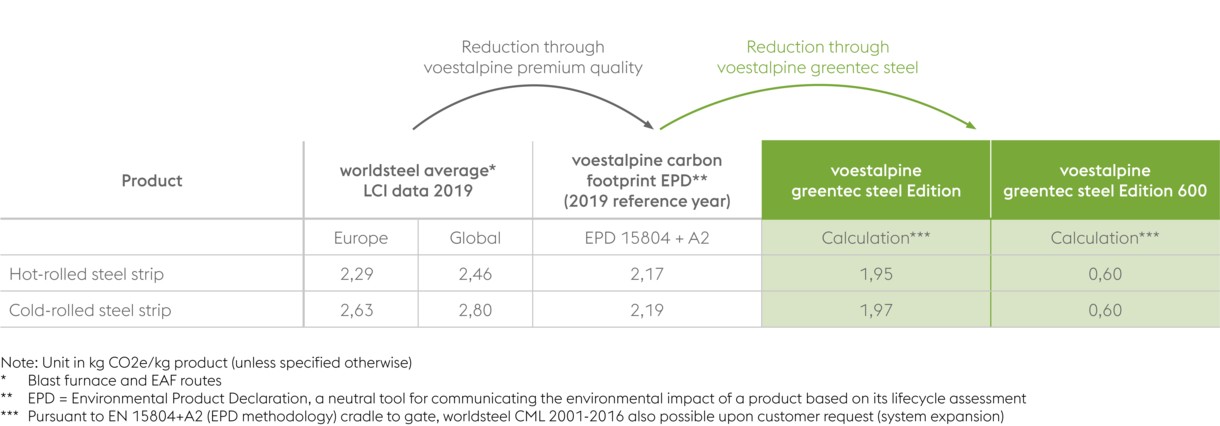

Now sustainable for the future in the greentec steel Edition made by voestalpine

Sustainability is more than a goal for voestalpine. It is part of our responsibility and our corporate culture. True to our vision of CO2-neutral steel production by 2050, we consistently focus on innovation and efficiency. At the Linz production site, we are already making an important contribution to reducing carbon emissions in our new optimized production route. As a customer, you have the opportunity to become an active part of this development: The greentec steel Edition of our cold-rolled and hot-rolled steels make it possible for you to purchase premium high quality from voestalpine with a reduced carbon footprint and with material properties that remain unchanged.

Application recommendations for enameled steel

Enameled steel opens up new dimensions in the design and manufacture of high-quality products. Its special behavior during forming, enameling and joining make it an ideal material that combines function, longevity and design. Targeted handling along the entire process chain is crucial in order to exploit the full potential of the material.

Forming

The enameling steels made by voestalpine have been specially developed for the high demands of forming processes. They are based on mild, unalloyed deep-drawn steels and IF (interstitial free) steels that feature excellent cold formability. Depending on the grade, they are suitable for simple to highly complex geometries.

Enameling

The enameling grades made by voestalpine are suitable for enameling on one or both sides. The material can be degreased, sandblasted or pickled as required. Common enameling processes include wet spraying, electrostatic liquid coating and powder enameling. The steels are typically enameled at approximately 830 °C. The optimized chemical composition ensures best adhesion and freedom from blisters.

Joining

Enameling steels can be joined easily in any common joining process. They are suitable for each standard welding process, e.g. resistance welding, spot welding and inert gas welding, as well as for alternative joining processes such as clinching and folding.