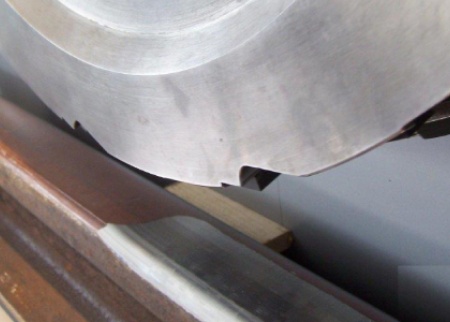

During preventive milling, the decarbonised surface layer of the rail is symmetrically removed in one operation in conditioned circumstances. This layer has a thickness of at least 0.7 mm. By executing this task prior to the installation of the rail, the downtime is considerably shortened. In addition, it turns out that after the preventively milled rails are installed, there is no need for an additional first and second cyclical grinding operation.

Prior to the rails’ use, it is important to remove their ‘mill scale’ to prevent premature damage. This prolongs the rails’ life span.

The rails are milled symmetrically in our milling factory. In this way, the trains can use both sides of the rail instead of only one side. As a result, issues such as the direction in which the train moves or the direction into which the rail is delivered are no longer of any concern. And this makes the work of the railway contractors much easier.