Tags:

Ever-increasing electrification of power trains in the automotive and other industries has led to rapid changes in the design of electric motors. Even the smallest motor efficiency improvements have led to an increase in range while maintaining the same battery capacity. Electrical steel has made a decisive contribution in this improvement.

voestalpine provides full support to its customers in this process and expands its range of electrical steel grades on a continual basis: Following startup of one of the most modern electrical steel annealing lines in 2014, a further milestone was a double-digit-million investment in the company’s rolling mills. The outcome is impressive:

In a continuous cold rolling process, high-alloy electrical steel can now be produced in thicknesses of less than 0.3 mm as well as in widths of more than 1300 mm.

For example, electrical steel with a thickness of 0.27 mm (isovac® HPNO27-14 Y420) is now the standard in production. Sample material in thickness 0.25 mm (isovac® HPNO25-13 Y420) is also available upon request.

In order to facilitate grade selection, the guaranteed yield strength has now been integrated into the grade name, for example Y420 stands for a minimum yield strength of 420 MPa.

The continuous cold rolling process results in quantitative and qualitative material improvement: The quantitative improvement is based on the fact that continuous cold rolling process is very efficient and fast compared to the reverse rolling process. This increases the output volumes for e-mobility. The qualitative improvement lies in the extremely homogeneous material that permits a continuous cold rolling process for such low thicknesses and high widths. This major technological leap is also reflected in our results.

Uniform grain sizes, uniform distribution and very small differences in chemical composition form the foundation for extremely homogeneous magnetic and mechanical properties from the first to the last meter of the final product. The material can be perfectly blanked, thus allowing maintenance of the narrowest component tolerances. The uniform magnetic properties provide the basis for highly consistent performance in manufactured motors.

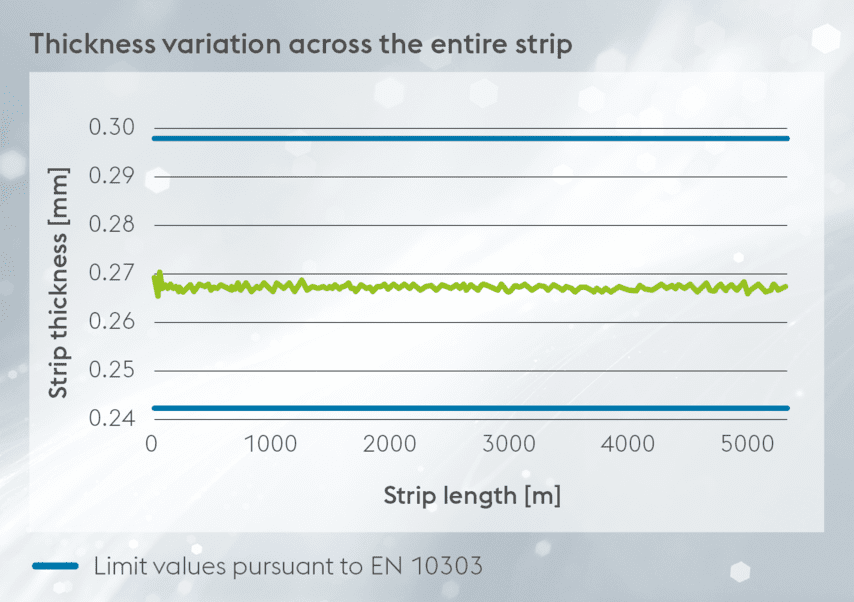

The desired final thickness is achieved in a series of successive cold-rolling steps. The result is highly uniform thickness in the electrical steel across the entire strip length. The thickness values remain well within the specified standard limits. The uniform thickness makes it possible for customers to efficiently produce stacks because the required stack height can be achieved with a highly consistent number of laminations.

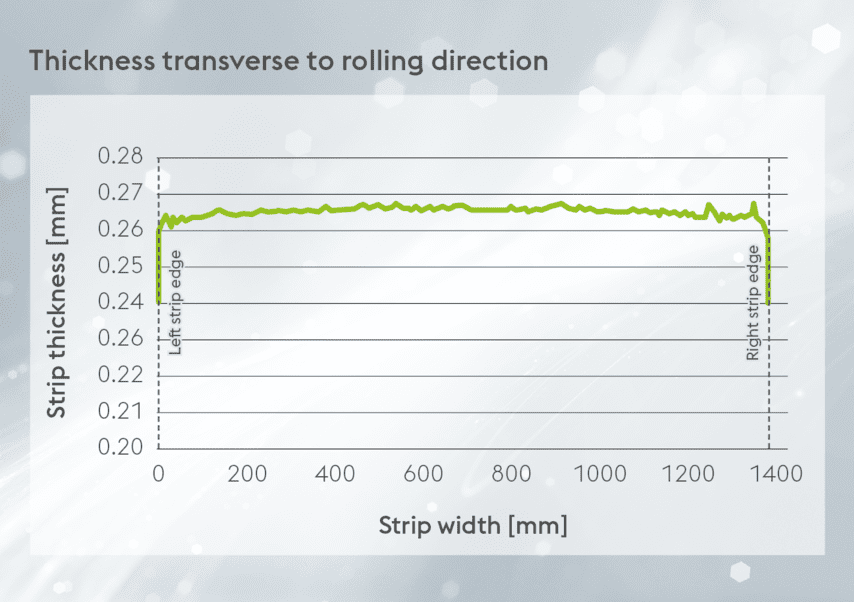

The narrow geometric tolerances required in motor components are achieved by decisively important factors such as excellent strip thickness consistency across the entire length of the strip as well as transverse to rolling direction. In the worst case, a banana-shaped component is created as a result of the stacked, wedge-shaped laminations. Highly uniform thickness across the strip width enables the production of straight rotors and stators from stacked laminations.

The results of our new investments are very positive: voestalpine provides support to its customers in automotive applications with highest-quality grades in thickness ranges down to a minimum of 0.25 mm and with an efficient continuous cold-rolling process. This results in unique widths of more than 1300 mm.