Keynote address by Dr. Karin Niederwimmer

Coiltech Pordenone is the leading trade fair in Italy in the coil winding industry and focuses on materials and machines used in the production of electric motors, generators, transformers and coil windings. The trade fair registered more than 3000 international visitors in 2023 with great emphasis on mobility and energy generation. Together with Metalservice, voestalpine presented the latest news about Backlack, as well as innovations in the field of electrical steel and isovac® prime services.

The World Magnetic Conference also took place at the Pordenone fair, where Dr. Karin Niederwimmer, Technical Quality Specialist in the field of electrical steel at voestalpine, presented to an interested audience for the first time a new method for the assessment of varnish squeeze-out in Backlack-bonded stacks.

The two most important quality criteria for Backlack-bonded stacks are high adhesive strength and the absence of varnish squeeze out on the edges of the stack. International standards apply to the determination of adhesive strength. Varnish squeeze-out is evaluated visually by production personnel and is highly subjective. It is also influenced by external factors such as lighting.

Intensive research and development have been dedicated to this issue at voestalpine, and a highly effective solution to the problem has been devised.

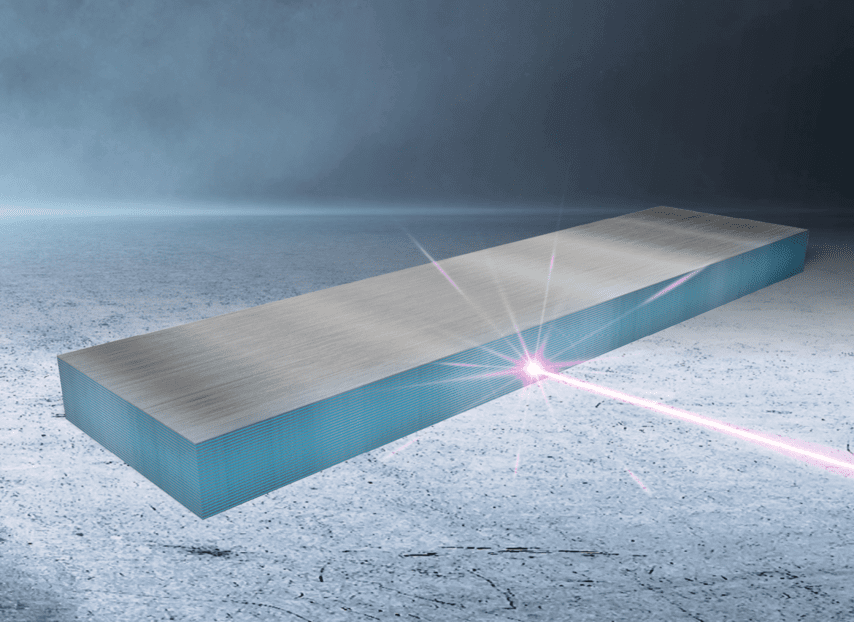

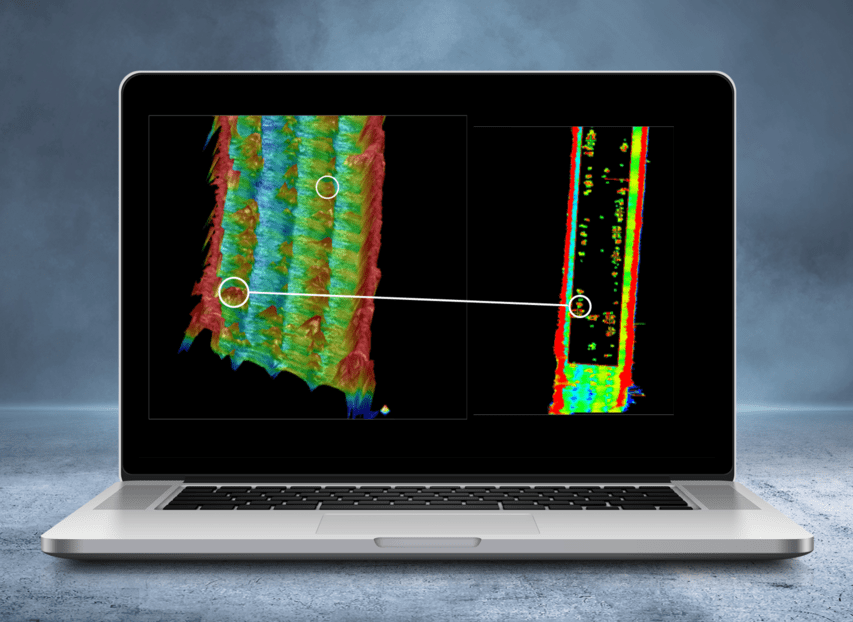

Laser triangulation is used to create a 3D point cloud on the front side of the bonded test specimen. Heretofore hardly recognizable excess material in the adhesive bond, which may be indicative of a varnish squeeze-out, are visualized and detected automatically. False assessments, for example caused by reflections in microscope images, are eliminated.

Schematic diagram of the test procedure and measurement result

Dr. Karin Niederwimmer clearly explained the great advantages of this test method as compared to conventional visual assessment. Impermissible material behavior is detected automatically, reproducibly and thus highly reliably. This objective initial inspection of Backlack-coated material at voestalpine reduces processing issues to 0. We call it 0% trouble.