Hot forming steel up to 2000 MPa with a thin zinc coating

phs-scalefree 2000 is a special development in the field of lightweight automotive design that opens up new perspectives for the manufacture of high-strength components. The single-phase zinc-ferrite coating is our secret for success. It ensures excellent scale protection with outstanding hot forming properties and provides additional corrosion protection.

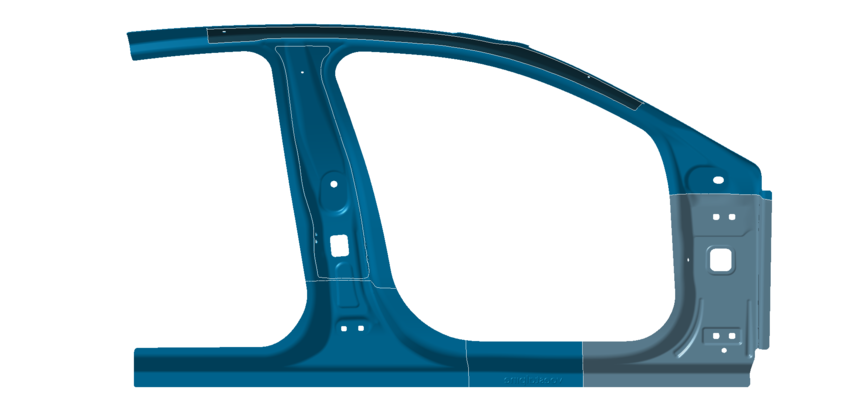

phs-scalefree® is the quality solution for B pillars, internal structural components or even components located in secondary appearance areas. Galvanized manganese-boron steels for hot forming are also recommended for large components.

Unbeatable in manufacturing and component quality

Premium coating appearance through surface homogeneity

Thanks to its superior surface finish, phs-scalefree® excels in applications where both technical performance and visual quality are critical. This allows for the production of components in secondary visible areas without having to compromise on design or functionality.

Thin zinc coating for processability

- A special PHS furnace atmosphere is not required. The zinc layer protects the PHS surface from scaling – the high emissivity of the zinc-iron surface ensures rapid heating and makes it possible to reduce the furnace temperature.

- phs-scalefree® steel grades exhibit very good adhesive bonding properties because of their special surface coating.

- phs-scalefree® is designed for the direct or indirect process.

PHS process for freedom of design

- More demanding geometries can be produced in the direct process as a result of the lower friction in the hot forming tool (compared to uncoated or aluminum-silicon coated PHS).

- Complex geometries, including undercuts, are possible in the indirect process as a result of cold forming in the initial process step.

High-strength components for greater safety

- The high-strength components guarantee the best crash performance with the lowest weight.

Scale protection for higher cost savings

- The clean and scale-free processes ensure lon ger tool service life, reduced part cleaning requirements and longer tool cleaning intervals.

Lightweight design for sustainability

- High strengths up to 2000 MPa ensure lower thick nesses that lead to lower fuel consumption and reduce carbon emissions.

- Larger components such as galvanized door rings lead to less material use. The number of individual components and joined areas can be reduced.

All-in-one expert

Benefit from the materials expertise of the voestalpine Steel Division and the manufacturing expertise of the voestalpine Metal Forming Division.

phs scalefree 2000: hot-forming steel with zinc coating

phs-scalefree® is a hot-forming steel up to 2000 MPa with a thin zinc coating and offers new possibilities for high-strength components in lightweight automotive design. In addition, phs-scalefree® is suitable for processing in both direct and indirect hot forming process.