Steel meets new perspectives

Sustainability, electromobility, our world on the move. What moves Toyota? What moves the development specialists at Bertrandt or the steel experts at voestalpine? What moves newcomers like Fisker or NIO? What is it like for Magna Steyr to work with a startup? Automotive Dialogue provided some answers, suggestions and an exchange of ideas.

This has been the second online event of this kind that was organized by the voestalpine Steel Division. The response has been tremendous. Roughly 1000 participants went online to join the afternoon event. Established OEMs and startups. Information and inspiration. From experts for experts in the course of entertaining presentations and with every participant being able to directly ask questions.

Insight and overview

An overview of the session content can be found here. If you are interested in the entire stream and would like to have more information, please click the button below.

Perspectives on mobility

What does the future look like in the automotive industry and with respect to mobility in general? How to deal with the future were the fundamental considerations during the opening of the Automotive Dialogue.

Reliability as a basis

Despite all the challenges of the future, one virtue of the automotive industry must not be lost: stability - and thus the security and ability to rely on each other and to plan.

Concrete predictability?

Caution is advised when making specific statements about what will occur, when, and to what extent. Even the best analysts can miss signs that may be small at the time, but become significant and large as time goes on. True fortune tellers can only base their predictions on past experience. In addition to this, we often lack the imagination for disruptive and new developments.

Perspectives and scenarios

One way to deal with uncertainties is to develop scenarios and perspectives instead of point-by-point predictions, and to think in terms of strategic horizons in order to be more flexible.

Dialog with each other

The future is created as we work together in harmony. Automotive Dialogue sees itself as a platform that unites steel developers, users, topics such as new mobility and sustainability, startups and established OEMs. The event provides a platform to exchange ideas, learn new things and benefit from each other’s experience.

Toyota's roadmap for carbon neutrality

Toyota, one of the world's leading automotive brands, is also a leader in the field of environmental responsibility. The objective is to be a climate-neutral company with climate-neutral products by 2050. Toyota is working extensively on driving development in this direction.

Objectives and current status

As one of the first OEMs, Toyota defined the challenges in achieving CO2 neutrality back in 2015. Today, 100% green electricity is supplied to the European production sites in France and the Czech Republic. Both sites are scheduled to achieve climate-neutral production as early as 2030, and global production five years later. Climate neutrality for the entire company and its products is scheduled for 2050, in Europe a few years earlier.

e-Competence as a core factor

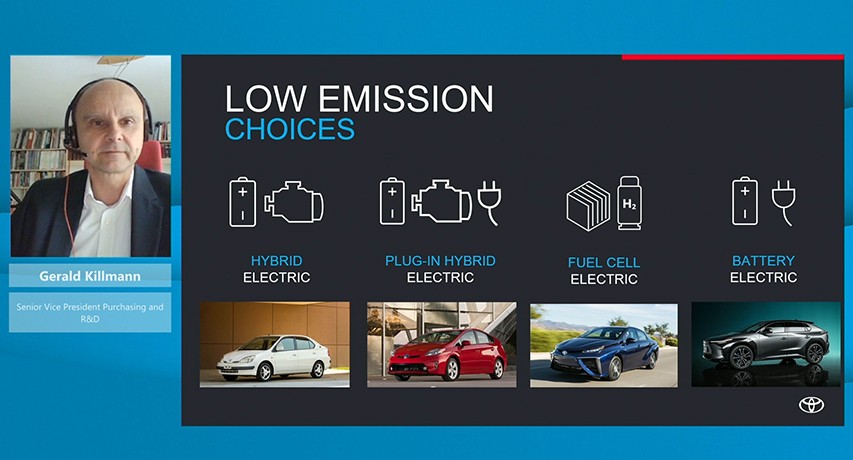

Toyota has experience. Since 1997, Toyota has put 20 million highly electrified cars on the road worldwide. E-vehicles are the future. The whole range of electrified vehicles is in the portfolio: hybrid, plug-in hybrid, fuel cell, battery. The focus will be on hybrid and battery vehicles.

Toyota commitment to affordability

"Our path is to reduce CO2 by increasing electrification and offering affordable environmentally friendly vehicles. This is how we contribute to the democratization of environmentally friendly individual mobility."

Steel development partnership

Strength and formability are essential criteria for steels, particularly with respect to crash safety. Toyota and voestalpine jointly developed TBF steels at strengths of 980 MPa and 1200 MPa, making it possible to reduce component thickness and optimize geometries. This also makes it possible to make components lighter, thus benefitting the factors of energy consumption and the environment.

Technological advancements

The 5th generation of Toyota hybrid vehicles will have a 40% lighter lithium-ion battery pack with higher performance. In zero-emission, purely battery-powered vehicles, the Toyota bZ sub-brand is leading the way. The first model built on a dedicated platform (eTNGA) offers four-wheel drive in full SUV performance with two engines. In addition, the world's first bipolar NiMH battery is in production. It is smaller, lighter and requires less rare earths.

Fuel cell technology

Second-generation fuel cell modules are now in production. Hydrogen energy solutions range from mobile applications such as ships, trains, buses and passenger cars (Toyota Mirai) to supplying cities. As an example, the Eiffel Tower was recently illuminated with energy from Toyota fuel cell modules.

Question from the audience

What does the future hold for battery electric vehicles (BEVs)?

Mr. Killmann: We believe every battery, even in hybrid vehicles, reduces CO2 emissions. The time for BEVs will undoubtedly have come once battery production capacities increase. We are prepared for this and are on the right track.

NIO user enterprise

NIO stands for smart electrified cars in the premium segment. NIO is characterized by innovative technology, appealing design and an interesting power supply. NIO always puts the user in center focus.

The company

Founded in 2014, NIO is a fast-growing company with 16,000 employees. The company headquarters is in Shanghai, and the global design headquarters is in Munich. 200,000 electric vehicles were sold by April 2022. With a first branch office in Oslo, the leap to Europe has already been made.

To shape a joyful life

NIO is guided by making life with an NIO as comfortable as possible. The latest model, the NIO ET7, for example, is said to have a range of 1000 km with pure electric drive. 33 cameras and sensors make NIO fit for autonomous driving in the future. Since the company was founded, the idea of a wireless software upgrade has been pursued for the operating system.

Innovative infrastructure

The plan is to build a network of energy supply points that can do more than just quickly recharge the battery: The entire battery pack can be replaced in 5 minutes. The customer can choose among various battery performance classes. And there is a cost advantage since the user can lease the battery. 900 of these battery swap stations have already been built.

Sustainability

This year, NIO is saying goodbye to plastic in the interior, and this plastic is being replaced by material taken from rattan palm trees. A German start-up gave NIO the idea of using it in the NIO ET7. The ET7 will premier in Europe this year. NIO collaborates with 160 partners, all of whom are working on CO2-neutral mobility for the future.

Question from the audience

Where and how will the battery swap station network be established?

Mr. Otto: There will be 4000 in 2025, 900 of them outside China. We are working with a leading oil company and service station operator in China. A memorandum of understanding has already been signed with Shell.

Strategy for sustainable battery lifecycle

With more than 50 company locations, the Bertrandt Group is one of the leading international engineering companies. The projects and content are constantly changing: Electromobility and sustainability are taking on great importance.

Performance and industries

Bertrandt takes a holistic approach throughout the entire lifecycle and offers complete product development from the initial concept to the ready-to-make product. The largest customer sector is the automotive industry, followed by the aerospace and medical technology sectors.

Megatrends

Megatrends that change projects and products are digitalization, autonomous driving, connectivity, i.e. the link with the software electronics sector, and the overarching electromobility and sustainability.

Sustainability for high-voltage batteries

Development of high-voltage batteries is the core business in the field of electromobility. The Bertrandt approach is lifetime maximization and cost reduction through a holistic view of battery life. Sustainability is a much more important issue today than it was just a few years ago.

A few years ago, the task was to develop a battery that was optimized for production and use. Remanufacturing, spare part logistics and recycling must now be taken into account as early as the initial development stage.

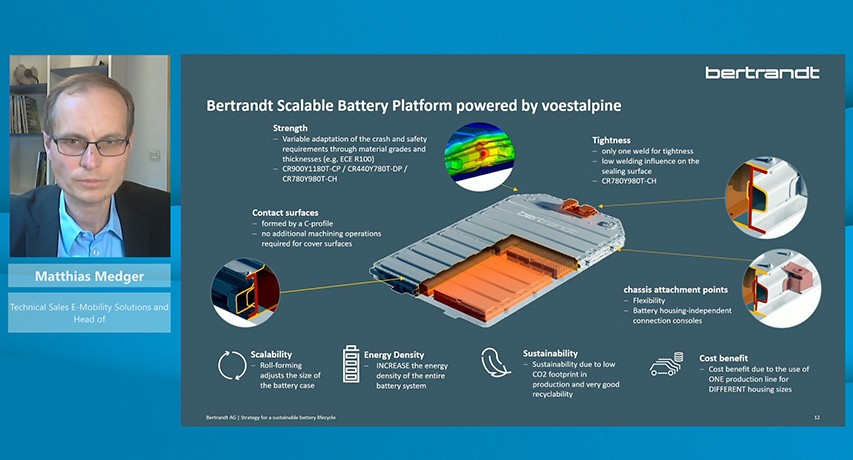

Bertrandt scalable battery box powered by voestalpine

voestalpine has contributed its expertise in steel and steel processing to this project, and Bertrandt has contributed its development expertise. The result is a scalable module solution for a battery box that can be manufactured economically, thus contributing significantly to sustainability and cost reduction.

Exemplary vibration test system

Bertrandt develops high-voltage batteries and also ensures that they can be validated efficiently and sustainably. The multi axis shaker table developed by Bertrandt can be used to simulate the lifecycle of a battery, whether it be in cold winters or hot summers. Loads of up to 850 kg can be applied in all 6 spatial axes, and the battery can be permanently charged with up to 1200 volts and +/- 1200 amps for a total output of 400 kW.

Question from the audience

Why did you use steel as the material for the scalabe battery box project?

Mr. Medger: Sustainability and cost efficiency were the reasons. You can create different sizes of battery boxes in one line when using steel as the material. Steel is ideally suited to mass production in the rollforming process.

ultralights by voestalpine – innovations for lightweight automotive design

In the ultralights field of expertise, voestalpine combines its material expertise with lightweight automotive design and offers a steel portfolio that meets the highest and most diverse requirements. Permanent development is part of the program.

Cold-forming steels

With over three decades of experience in the field of advanced high-strength steels (ahss), voestalpine is a development pioneer and expert for high-strength cold-forming steels. The portfolio

- ahss classic includes complex-phase steels characterized by high bending and flanging properties and dual-phase steels with high tensile strength, uniform elongation and total elongation, as well as excellent deep-drawing properties.

- ahss high-ductility, a product further developed by voestalpine in the classic ahss steels with an unprecedented balance of strength, bendability and weldability.

- martensitic steels for even higher strengths. These steels are recommended for roll forming. Coming soon: voestalpine martensitic steel at 1500 MPa.

- hot-rolled drive - for more thickness. They meet the requirements of VDA 239-100 and include grades with excellent local and global ductility.

Hot-forming steels

In automotive lightweight design, voestalpine is the partner of choice when it comes to the production of components from galvanized press hardened steels (phs) by means of hot forming. The spectrum allows components of the highest strength, complex geometries, high dimensional accuracy and best corrosion protection:

- phs-ultraform® for large and complex components in indirect hot forming

- phs-directform® for a wide range of components in direct hot forming

- phs-multiform® for high productivity in a multi-step process

- phs-scalefree®, the first hot-forming steel up to 2000 MPa for both direct and indirect hot forming with a thin zinc coating

Clear weight savings

Using a model mid-size car, voestalpine experts compared the original steels used with possible ultralights. The SLIMulation results speak for themselves: Innovative ultralights provide the same crash safety, yet with significantly reduced weight. You can find the weighty savings here: https://www.voestalpine.com/ultralights/en/Applications/Slimulations

Fit for the future

A new lab center for physical simulation is currently under construction. voestalpine executes the entire process chain from molten steel to the finished product on a lab scale. Trial and error take on a new dimension.

The TransVer project is upgrading hot-dip galvanizing lines 4 and 5. After the revamp, it will be possible to supply steels of even higher strengths with further optimized elongation values in an even wider range of dimensions.

Question from the audience

Do you see strength limits in steel development?

Mr. Hebesberger: The limits will be 1500 MPa or perhaps 1700 MPa for cold-forming steels. The limits will probably be 2000 MPa for hot-forming steels. We see development potential in formability and processability, i.e. weldability.

The toolbox - how the Metal Forming Division meets the challenges of mobility

Innovative steels, processing expertise and innovative strength are among the core competencies of voestalpine. The metal formers at voestalpine meet the challenges of the future with an extensive toolbox.

Changing challenges

In the automotive world, the topics of lightweight design, safety, and affordability are driving factors from the perspective of the Metal Forming Division. Flexibility is added to both production and the supply chain when we look at our mobility path into the future. Finally, sustainability.

Sustainability

"Co2untdown to Zero” is how the Metal Forming Division is pursuing the goal of being CO2-neutral by 2035. The entire value chain is being reviewed, potentials defined and measures implemented. Even today, environmentally friendly electricity comes from the company's own hydroelectric power plant and through solar energy.

Innovative product solutions

Two current examples from the field of electromobility:

- voestalpine has developed full-face-bonded laminations for rotors and stators in electric motors. They ensure quieter running, maintain full magnetic properties, help improve performance and are ideal in economical high-volume production.

- Battery boxes are elements that are crucial to the safety of electrified vehicles. voestalpine has been building up targeted expertise in the field of battery boxes for a number of years and offers safe solutions with high-strength and ultra-high-strength steels.

Steels and forming technologies

Each development always focuses on formability. Cold forming, hot forming, roll forming: voestalpine offers a complete portfolio in high-strength and ultra-high-strength steels. A strength of 2000 MPa is now a reality with the development of the hot-forming steel phs-scalefreeâ.

Ultra-high-strength steels are also under development for exposed panels and will complement the portfolio.

Manufacturing

"We can eat what we cook too!" The companies of the Metal Forming Division are economical manufacturing partners for parts and components. Flexibility and performance are permanently optimized with a comprehensive approach that even includes artificial intelligence.

Question from the audience

Does voestalpine make a difference when working with established OEMs and newcomers to the market?

Mr. Traxler: No. The customer is king to us. We want to make the best possible contribution to the success of all our customers with our products and expertise from manufacturing and supply chain management to logistics.

Exposed panels in the change of time

Inner beauty is not everything. When it comes to automobiles, external beauty also plays an important role. A journey through time shows how the beauty of exposed panels has evolved. Today, perfect surfaces are a must, but exposed panels must also withstand the ravages of time without rusting.

Wooden beginnings

The first self-propelled vehicles, like carriages, were handcrafted from wood. It soon became very clear: Wood splinters easily and can only be steamed to be bent into simple curves. Metals began appearing in car bodies as early as the first decade of the 20th century, almost in parallel with new manufacturing techniques such as welding. The Dodge brothers introduced the first all-steel car in 1914.

Salt corrodes galvanized steel

After the Second World War, salt spreading ensured greater winter safety on the roads. The result for cars was a shocking rust record. Galvanized steel posed a range of problems. Spot welding and painting did not work as desired, and surfaces were uneven. Until the 1970s, galvanized sheet steels were used almost exclusively for non-visible body parts. New technologies (air knives) improved the situation. in 1985, the first fully galvanized Audi went into serial production.

From around 1990, aluminum was increasingly used for exterior parts. After the turn of the millennium, the coating range was expanded with the new ZnMg coating.

Thinner coating layers, new challenges

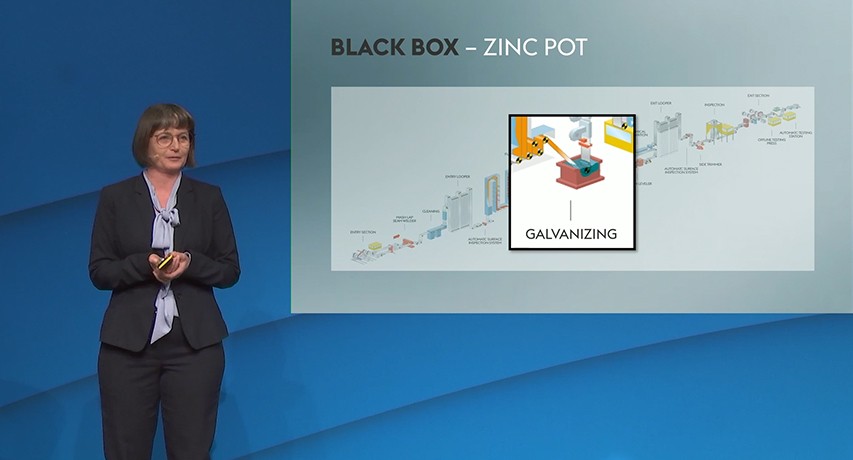

Integrated coating processes make it possible to reduce coating thickness. This reduction, however, significantly reduced the tolerable defect size in the coating layer. The critical particle size was reduced to about 20 to 30 µm, which is equivalent to about half the thickness of a human hair. Unfortunately, the formation of iron-aluminum particles cannot be completely avoided, since iron is continuously dissolved from the steel strip into the zinc bath.

Fluid dynamics process model at voestalpine

A computer-aided fluid dynamics process model developed by voestalpine enables a better understanding of the fundamental processes in the zinc bath. We know when, why and how many of the iron-aluminum particles precipitate. This makes it possible to establish optimized production schedules to achieve the highest-possible surface perfection.

In a further step, the model will be further developed as a digital twin of the zinc bath. This will make it possible to detect critical conditions in the zinc bath at an early stage. The operator can simulate scenarios to find the best countermeasures before critical defects are visible on the strip.

Question from the audience

Which material will stay in the race in the field of exposed automotive panels, steel or aluminum?

Ms. Traint: 20 years ago I would have said aluminum. Today we see more and more steel. I think both materials will remain in use.

Leading by disruption: the Fisker story

"Teamwork makes a dream work." Henrik Fisker, who takes a disruptive approach as an automaker, and Kurt Bachmaier of Magna Steyr on the collaboration of a newcomer to the market with an established automotive supplier.

The Fisker car philosophy

Electric, sustainable, fast. If you buy the latest car on the market today, the technology is about four years old. That's how long it takes from design to serial production. "It should be faster than that, even with a revolutionarily sustainable design," says Henrik Fisker about his philosophy.

The Fisker Ocean

The Fisker Ocean (the first Fisker model) is a 100% electric SUV that was brought to market in record time by Magna Steyr. The model is built at the Magna plant in Graz. Prototypes are currently being manufactured. Serial production will begin on 17 November this year.

MAGNA Steyr

The experienced automotive supplier has already manufactured over 3.7 million vehicles, developed over 40 of them on its own and offers the entire value chain from customer vision to serial production. Even if something completely new is created, Magna uses its experience, infrastructure and existing equipment. This shortens the time to market, and the investment costs can be reduced. One of the big advantages is that Magna is sustainably oriented. Production at the plant in Graz is CO2-neutral . More production facilities will soon follow throughout the world. Reasons for start-ups to choose Magna as a partner.

Cooperation with start-ups

Working with a startup is different from working with a traditional automaker. Kurt Bachmaier from Magna Steyr: "One difference is the speed with which decisions are made. You do not have to push through any levels. Startups don't have large organizations and backups. They question everything to see if it can't be done faster and more efficiently. This pushes us in the right direction as an established company."

Question from the audience

What are the biggest challenges to established OEMs and startups in the future?

Mr. Fisker: The award. Many electric vehicle manufacturers are targeting the luxury segment. We need to build affordable electric vehicles if we are aiming for success and want to make a difference in our world.