Best strip flatness, highest strength, excellent formability

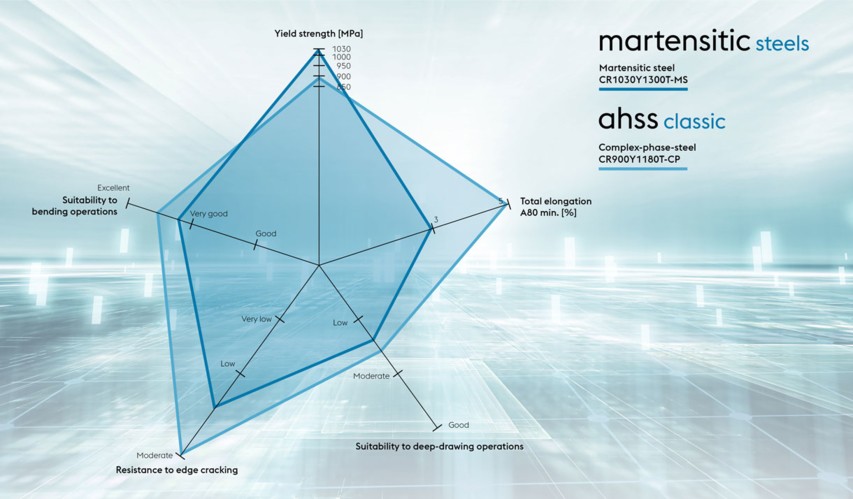

The martensitic steels of voestalpine are characterized by excellent formability during bending and roll forming as well as by highest strength. Their property profile is perfect for lightweight automotive design and for safety and crash components in cold forming. The material and forming properties are convincing, and the remarkable strip flatness of the steel strip is an advantage appreciated by processing firms.

Excellent combination of properties.

Martensitic steels such as CR1030Y1300T-MS (MS1300) close the gap in strength when compared to hot-formed steels. With this latest steel development, voestalpine provides a portfolio with minimum tensile strengths ranging from 1100 to 1300 MPa. They supplement hot-formed steels in the manufacture of safety and crash components such as side members, rocker panels, seat rails and car body components.

The extremely high resistance to edge cracking during the forming of punched edges is also important to emphasize. This is due to the single-phase martensitic structure.

A cool solution.

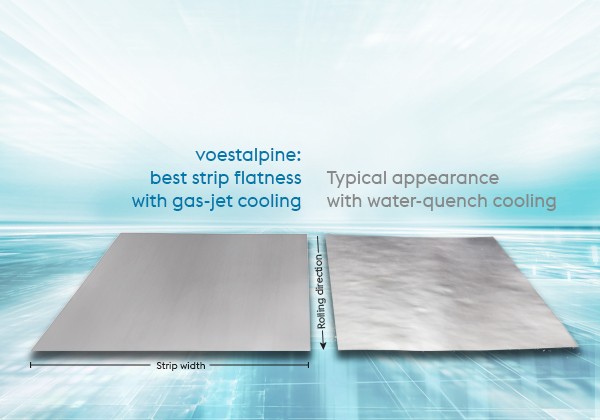

The secret of homogeneity in material properties and strip flatness lies in the special, perfectly coordinated annealing and cooling technology of voestalpine, which leads to martensitic transformation. In contrast to conventional cooling (water quenching), voestalpine uses finely adjustable gas-jet cooling.

Customer-certified

The CR1030Y1300T-MS grade has already been approved by customers, with the steel achieving particularly high scores for its uniform material properties and excellent strip flatness. The subsequent series deliveries also confirm the outstanding, consistent product properties of MS1300 and thus the high quality of the production technologies and processes implemented at voestalpine. The ultra-high-strength steels are available in either bright-finished or electrogalvanized condition, depending on corrosion resistance requirements.

Overview of main benefits

- Available with minimum tensile strengths from 1100 to 1300 MPa

- High ratio of yield to tensile strength

- Excellent cold formability in bending and roll-forming operations

- Best forming properties of punched edges based on high resistance to edge cracking

- Best strip flatness

- Good weldability

- High crash energy absorption

- Corrosion-resistant based on electrogalvanizing

| EN 10338 and EN 10346 | VDA 239-100 | Special voestalpine grade |

| - | - | CR860Y1100T-MS |

| - | CR1030Y1300T-MS | - |

Carbon footprint greentec steel product

greentec steel product | Maximum carbon footprint [kg CO2e/kg steel] 1) |

Cold-rolled steel strip | 2.15 |

Hot-dip galvanized steel strip | 2.30 |

| Electrogalvanized steel strip | 2.30 |

1) The carbon footprint is calculated pursuant to worldsteel CML 2001-2016 (system expansion) on a cradle-to-gate basis.

All products, dimensions and steel grades listed in each voestalpine supply range are available as greentec steel.