Schwaebisch Gmuend gets electricity from the roof

voestalpine Automotive Components Schwaebisch Gmuend is one of six players in the photovoltaic field in the Metal Forming Division. Therefore, it makes sense to also use the company's own roofs for the generation of solar energy.

Roofs become power stations.

"With our roof system, we are contributing to the Division's goal of climate-neutral production by 2035," confirms Andy Werner, team leader of the infrastructure team. "Around 14,000 m² of new PV modules have been installed recently on our roofs." On the remaining roof surfaces, additional PV modules have already been producing green electricity for ten years, which is fed into the public grid via an operator.

The peak output of the new system is expected to be 1,800 kWh, assuming 1,000 optimal hours of sunshine per year. From this, the Schwäbisch Gmünd-based company calculates an annual saving of 600 tonnes of CO2 emissions. After the project had been approved in September 2021, the plant was successfully commissioned a good year later. An invitation was extended on 3 November 2022 to celebrate together with customers, suppliers, fitters and representatives of the city. From now on, solar power produced here covers nearly 10 % of the electricity demand at the site.

The installation and commissioning of the PV system was carried out centrally by a cooperation partner of voestalpine Automotive Components Schwäbisch Gmünd. The inverters for the system come from Fronius, which, like voestalpine, is a guarantor of excellent quality.

iFIX in the process.

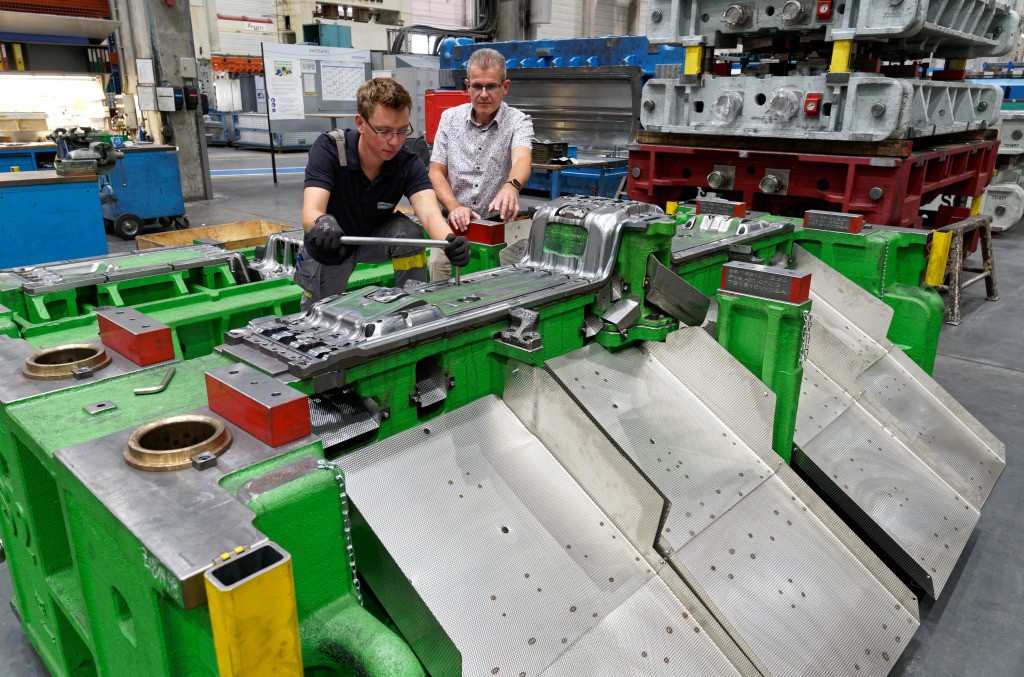

The speed of the installation of the PV systems on the roofs is also based on the advantages of the iFIX assembly system, which is produced in-house. This is because the elements, which consist of only one part, can be installed particularly quickly and without any tools. In Schwäbisch Gmünd, the east-west oriented iFIX variant "iFIX OW" is used. Its orientation allows for a yield of solar power that lasts well into the day. iFIX assembly systems are not only in demand at our own sites. The Europe-wide interest in the easy-to-assemble substructures is so great that a further optimized version will be available on the market soon. The production volume will even be increased to meet the high demand.For further details on the system click here