ultralights by voestalpine

Tags:

High strength, corrosion resistance and excellent forming properties are what you will find in the new hot-rolled, hot-dip galvanized steel grades of voestalpine. These grades meet and exceed the VDA 239-100 standard and are highly recommended for chassis components.

voestalpine is continually expanding its portfolio in the field of high-strength hot-rolled steels based on requirements in the automotive industry. The latest hot-dip galvanized developments add to our range of products and enable to efficiently produce complex component geometries with sophisticated forming techniques. The common denominator for our steel grades is reliable supply, high quality and the narrowest thickness tolerance. Our steel grades are characterized by special properties:

Available in an extended thickness range of up to 3.5 mm, the high-strength and hot-dip galvanized complex phase steel features high resistance to edge cracking and good bendability. Roll profiling is one of the big advantages. (available thicknesses: from 2.1 to 3.5 mm, max. width: 1,440 mm)

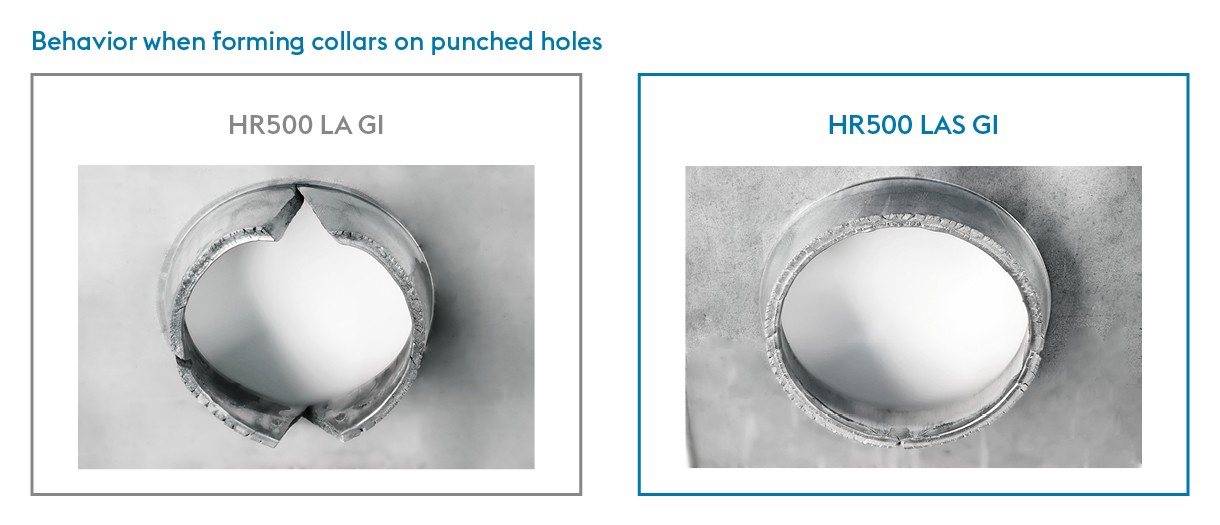

With excellent local formability and damage tolerance, this high-strength hot-dip galvanized ferritic-bainitic steel demonstrates its strength in the most demanding cold-forming operations such as punching and hole expansion. This special grade meets even the more stringent requirements of punched edges. (available thicknesses: from 2.0 to 3.5 mm, max. width: 1,500 mm)

The new grades HR500LA GI and HR550LA GI made by voestalpine complete the range of hot-dip galvanized microalloyed steels from HR380LA GI to HR700LA GI. High strength, very good formability, joinability and corrosion resistance all add to the list of advantages. (available thicknesses: from 2.0 to 3.5 mm, max. width: 1,500 mm; HR380 and HR420: Thicknesses: from 2.0 to 4.0 mm, max. width: 1,530 mm)

LAS stands for optimized manufacturing conditions for complex forming. This places the new microalloyed hot-dip galvanized steel in a class by itself with respect to the formability of punched edges. (available thicknesses: from 2.0 to 3.5 mm, max. width: 1,500 mm)

We would be pleased to provide you with additional information about the hot-rolled, hot-dip galvanized steel strips made by voestalpine. We will respond to your requests as soon as possible.