Flexibility is key in spare parts production

voestalpine Automotive Components relies on agility as success factor

voestalpine Automotive Components offers more than standard solutions—here, spare parts production is reimagined. The plant in Bunschoten is designed to offer OEMs maximum flexibility: from small series with just one part to large orders with 150,000 pieces per year. And all this without compromising on quality, efficiency, or delivery reliability.

Why is this important?

Spare parts production ensures the entire life cycle of automotive components. Vehicles stay on the road longer, model variants are increasing—and with them, the demand for customized, high-quality spare parts. With fast response times, voestalpine Automotive Components is a strong and reliable partner that gives OEMs a competitive edge.

Innovation & Technology: Developed for maximum flexibility

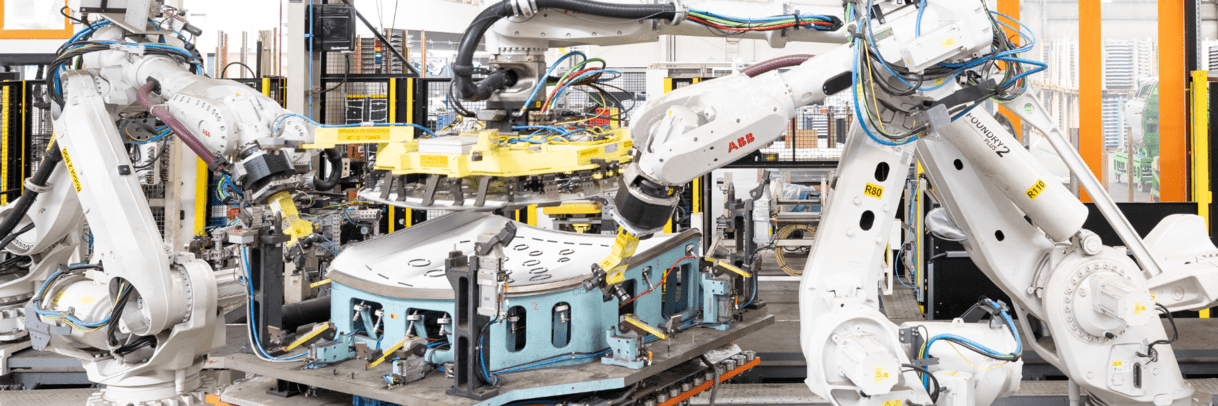

Flexibility is more than a promise—it is firmly anchored in the DNA of voestalpine Automotive Components. Thanks to modular production cells, a wide variety of parts can be manufactured on a single line. This creates maximum adaptability for dynamic markets and constantly changing requirements. But technology alone is not enough: expertise makes the difference. That is why voestalpine Automotive Components invests in people and know-how. Its own automotive academy at the plant in Bunschoten, Netherlands, ensures that the teams are always at the cutting edge – innovative, competent, and future-oriented.

Everything from a single source: Process reliability for OEMs

From raw material processing to final painting—every step takes place under one roof. This means fewer interfaces, less risk, and greater reliability. OEMs benefit from an integrated approach that guarantees the highest quality standards and absolute adherence to delivery dates.

The greatest strength of voestalpine Automotive Components lies not only in its state-of-the-art technology, but above all in the people behind it. Their expertise and uncompromising quality standards create the flexibility that characterizes our spare parts production.

Michael Stadler, Managing Director, voestalpine Automotive Components Bunschoten

Sustainability & efficiency: Shaping the future

Sustainability is more than a trend—it is a central part of our responsibility. voestalpine Automotive Components has a clear mission: 0% CO2 emissions by 2035. To achieve this goal, the group is consistently focusing on:

- Green energy for production

- Circular economy to minimize waste

- Initiatives such as "Circularity Street," which promote recycling and material reuse

"Circularity Street" means that components, tools, and molds are reused, reconditioned, or professionally dismantled and stored at the end of their life cycle or after the delivery obligation has expired. Non-reusable parts are sorted and recycled responsibly. This approach reduces waste, lowers costs, and strengthens the automotive industry's sustainable supply chain.

Contact us now

Would you like to learn more about the possibilities in spare parts manufacturing or find out how we can support your company?