voestalpine HPM at Formnext 2025: Key takeaways from the world’s leading additive manufacturing expo

Reflecting on Formnext 2025—what stuck with us

After the whirlwind that is Formnext in Frankfurt, the team and I have had some time to reflect on what made this year’s event so memorable. With 38,282 visitors and 804 exhibitors, it was the biggest and busiest additive manufacturing expo I’ve ever attended—and the most international, too, with nearly half the visitors and most exhibitors coming from outside Germany. If you ask me, Formnext is all about BIGGER. HIGHER. FASTER. And this year, it delivered on every front.

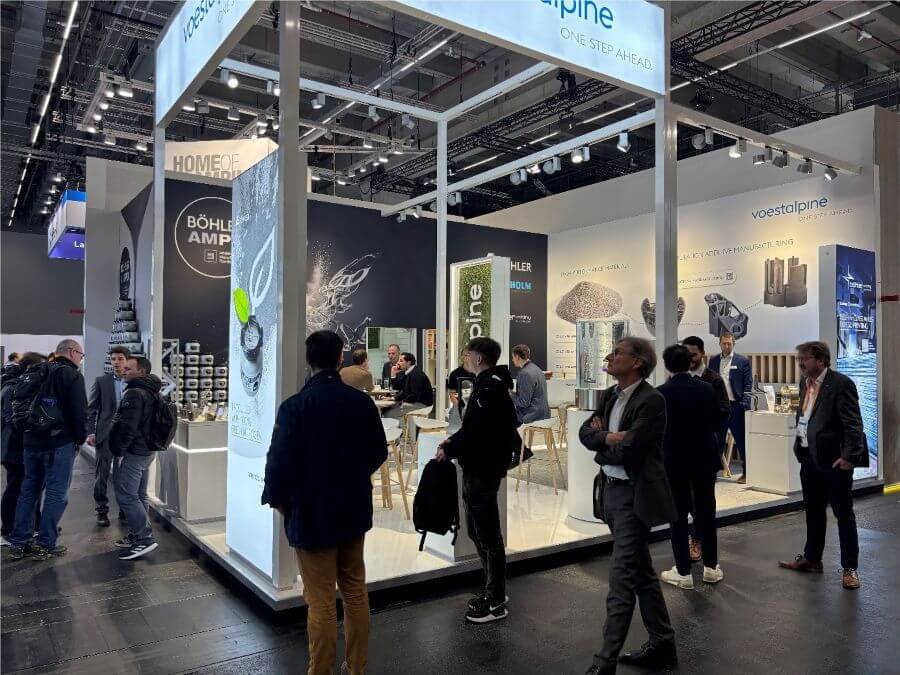

We were there with BÖHLER Edelstahl, voestalpine High Performance Metals Germany, the voestalpine Additive Manufacturing Center, and Uddeholm, showing off our capabilities across the entire value stream for Additive Manufacturing. Whether you need powder, components, or just a little help along the way, we’ve got you covered.

The Scene: From powder to partnerships

Looking back, what really stands out is how much the industry has grown. When we started selling powder in 2017, the average printer was 250x250x250 mm with one laser. Now, printers with build sizes up to 1m³ and multiple lasers are almost standard. Aerospace and defense are still leading the way, but tooling and medical applications are right there too.

And it’s not just about the machines getting bigger and faster. The conversations have changed. Not so long ago, people were still asking, “What is AM and what can I do with it?” Now, it’s all about, “How can I use AM to solve my problems?” That’s real progress, and it’s something I appreciate even more as I reflect on the discussions we had.

A day at the booth: From morning rush to afternoon “Jause”

Formnext was so busy that lunch didn’t happen until 4pm most days. In Austria (where I’m from), we’d call that a “Jause”—a late lunch or hearty afternoon snack. Every time I thought I’d finally get a break, two more interesting conversations would pop up. We had everyone from new leads to long-time partners stopping by. Some just wanted to know who we are and what we do; others dove straight into deep discussions about increasing tool life, choosing the right materials, or even sealing deals for next year.

Our Aquarium and Sand Clock were real conversation starters, and the 3D-printed demonstrator parts showed just how much is possible with AM these days.

Big thanks to Weijia Zheng, Ali Keshvaraz, and Johannes Bruckwilder from the vAMC for jumping into so many of those technical discussions. And of course, to Petra Grosser, Tiffany Nistovic, and Karin Lichey for keeping everything running smoothly.

What stood out: Sustainability and surprises

One thing that really stood out this year: sustainability and circular economy weren’t just buzzwords—they were everywhere. Not just at our booth, but all over the show. From carbon capture condensers made from aluminum to innovative solutions across the industry, it’s clear the focus is on responsible innovation.

And the best part? The conversation has shifted from “what’s possible” to “how do we make it work, better and smarter.” That’s the kind of progress that keeps me excited about this industry.

What’s next: Turning leads into partnerships

Now, as the team follows up on all those great conversations and leads, we’re turning potential into real partnerships. It’s a lot of work, but frankly, it’s what keeps us motivated and moving forward. A tradeshow is only as good as the team behind it, and I have to say, we had the best. The enthusiasm and engagement from everyone—Weijia, Tiffany, Ulrich, Daniel, Tilman, Thomas, Dieter, Petra, Ronny, Karl, Christin, and the whole Additive Manufacturing Center and Sales Team—made Formnext 2025 a truly valuable experience. And a special shout-out to our colleagues from BÖHLER Welding who shared the booth with us.

Wrap-up: See you next year!

Formnext 2025 showed just how far additive manufacturing has come—and how much further we can go together. Thanks to everyone who made it a success. I’m already looking forward to the next chapter!

Featured image: Weijia Zheng, Tiffany Nistovic, Ulrich Brandner, Daniel Diepold, Tilman Seifert, Thomas Schanzer, Dieter Bauernfeind, Petra Grosser, Ronny Krein, Karl Just