Solutions for plastic injection molding: voestalpine cavity insert

With growing customer demand for high quality plastic parts, injection molders face considerable production challenges to remain one step ahead. More than ever, potential customers weigh up both the technical and aesthetic functions of the plastic part when making a purchase decision. How well an injection molder can meet these customer expectations depends largely on the strength and quality of their value chain—from concept to finished product.

In this article we look out how voestalpine’s know-how, materials, technologies, and services can help plastic injection molders not only meet customer expectations, but also exceed them through superior solutions along the entire value chain. You will discover how the advanced features of the voestalpine cavity insert offers a range of benefits to add value to your plastic products and optimize your productivity.

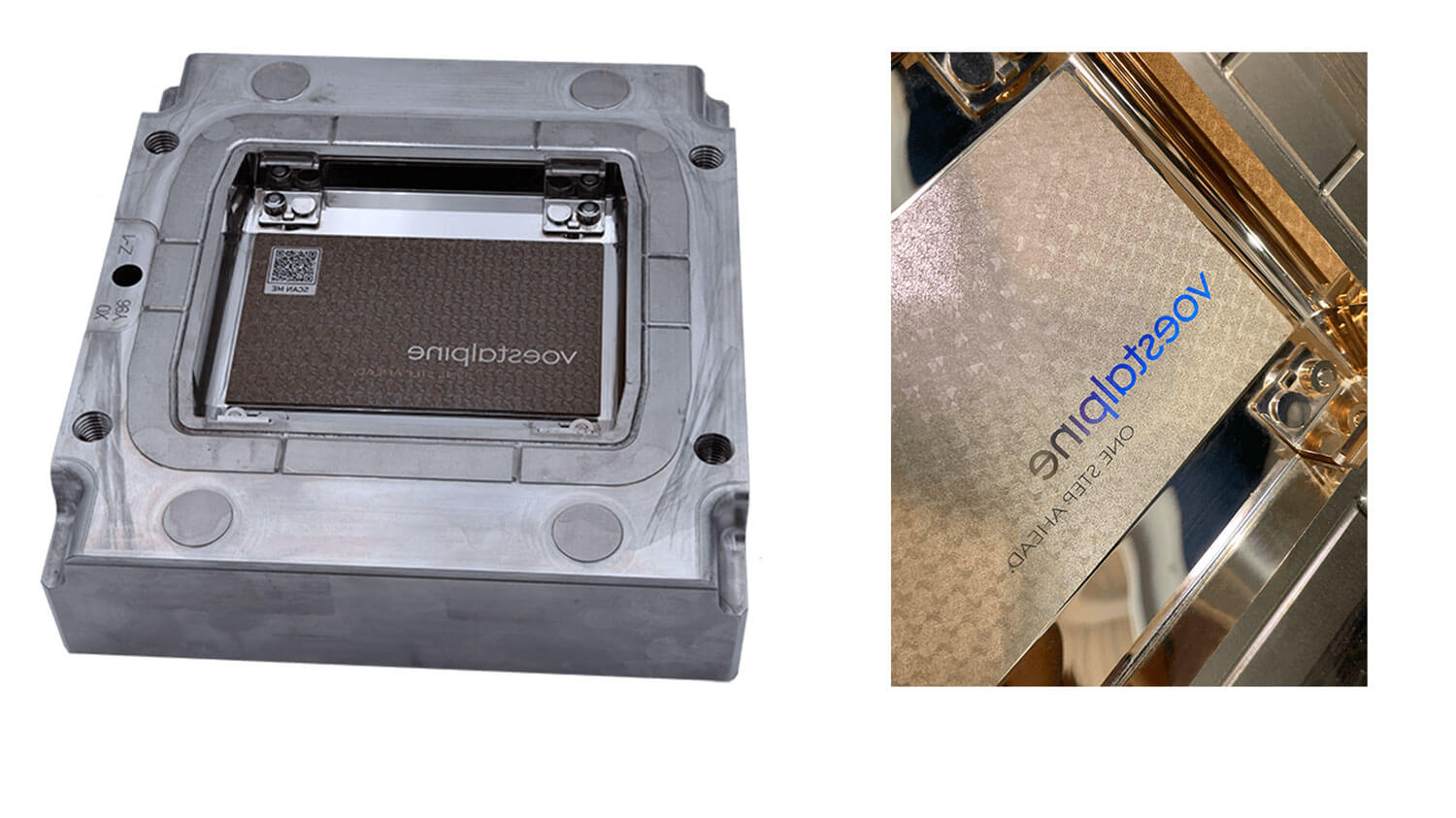

VOESTALPINE CAVITY INSERT AT FAKUMA

voestalpine High Performance Metals (HPM) recently showcased our solutions for plastic injection molding at the Fakuma international trade fair in Germany. Visitors were keen to find out exactly how the voestalpine cavity insert for an electrical housing cover demonstrates a seamless value chain—from concept to finished product. Together with our project partners*, our experts explained the many state-of-the-art design features of the cavity insert and their added value for customers.

This application achieves full elimination of the flow lines on the plastic part, and an overall cycle time reduction of 18%**. These improvements to the injection molding process and the part quality are enabled through variothermal temperature control of the AM conformal cooling channels. And new design features such as DigiMarc and the hologram are achieved through texturing, whereby the combination with the PVD coating ensures a protection against wear and thus a high lifetime.

** Compared to the original conventionally manufactured insert.

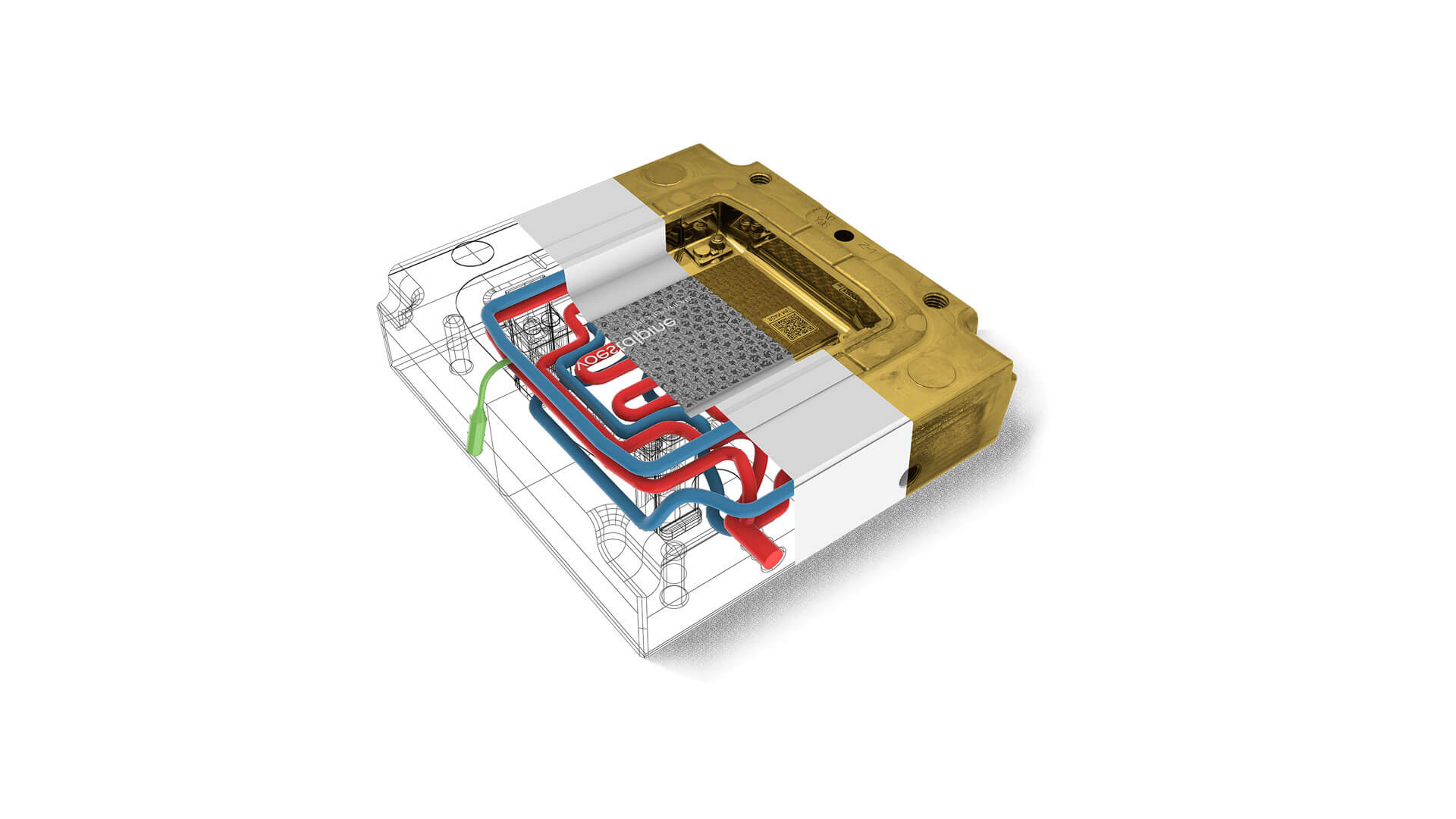

FULL ELIMINATION OF SURFACE DEFECTS

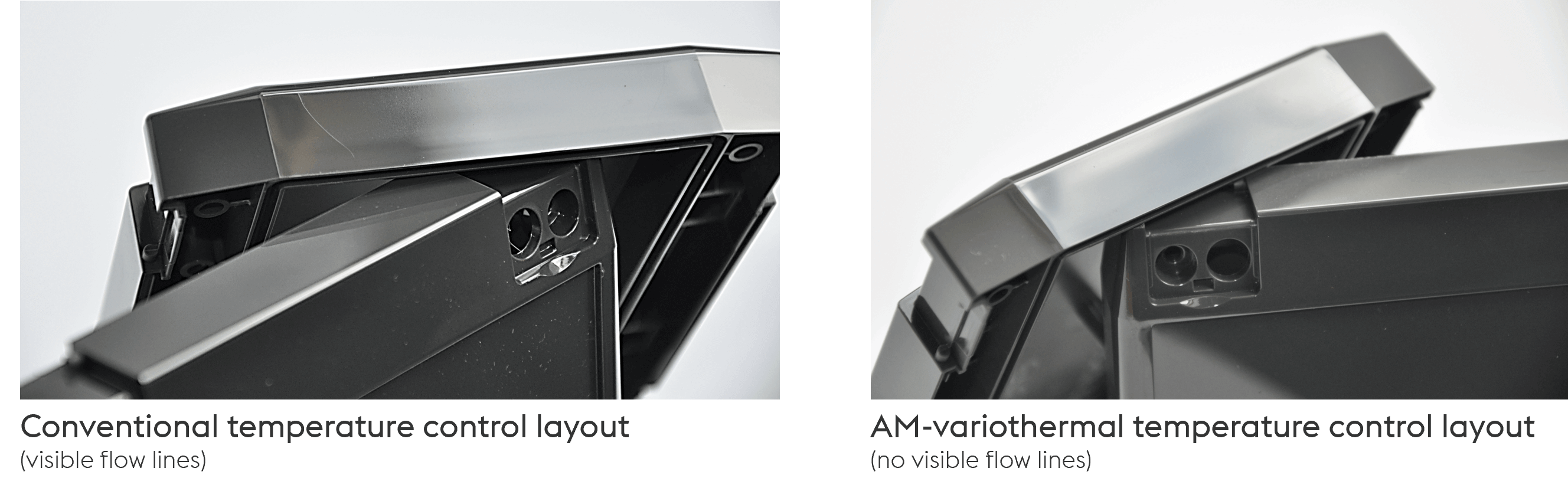

18 % CYCLE TIME REDUCTION BY LEVERAGING CONFORMAL COOLING

EXACTLY WHAT MAKES THE VOESTALPINE CAVITY INSERT SO UNIQUE?

In order to produce high-quality and technically complex parts, the required boundary conditions must be satisfied through the precise interaction of every manufacturing process in the value chain. Both the quality of the individual process steps (such as additive manufacturing, texturing, coating, etc.) and the seamless interaction between these are of equal importance. The voestalpine cavity insert for an electrical housing demonstrates the potential that can be unlocked by combining these state-of-the-art design and simulation methods, manufacturing technologies and materials.

From optimized thermal management and sensorized process monitoring for eliminating defects such as flow lines and improving productivity to unique wear-resistant surface texturing for integrating an invisible watermark (DigiMarc), the many cavity insert features and benefits are outlined below.

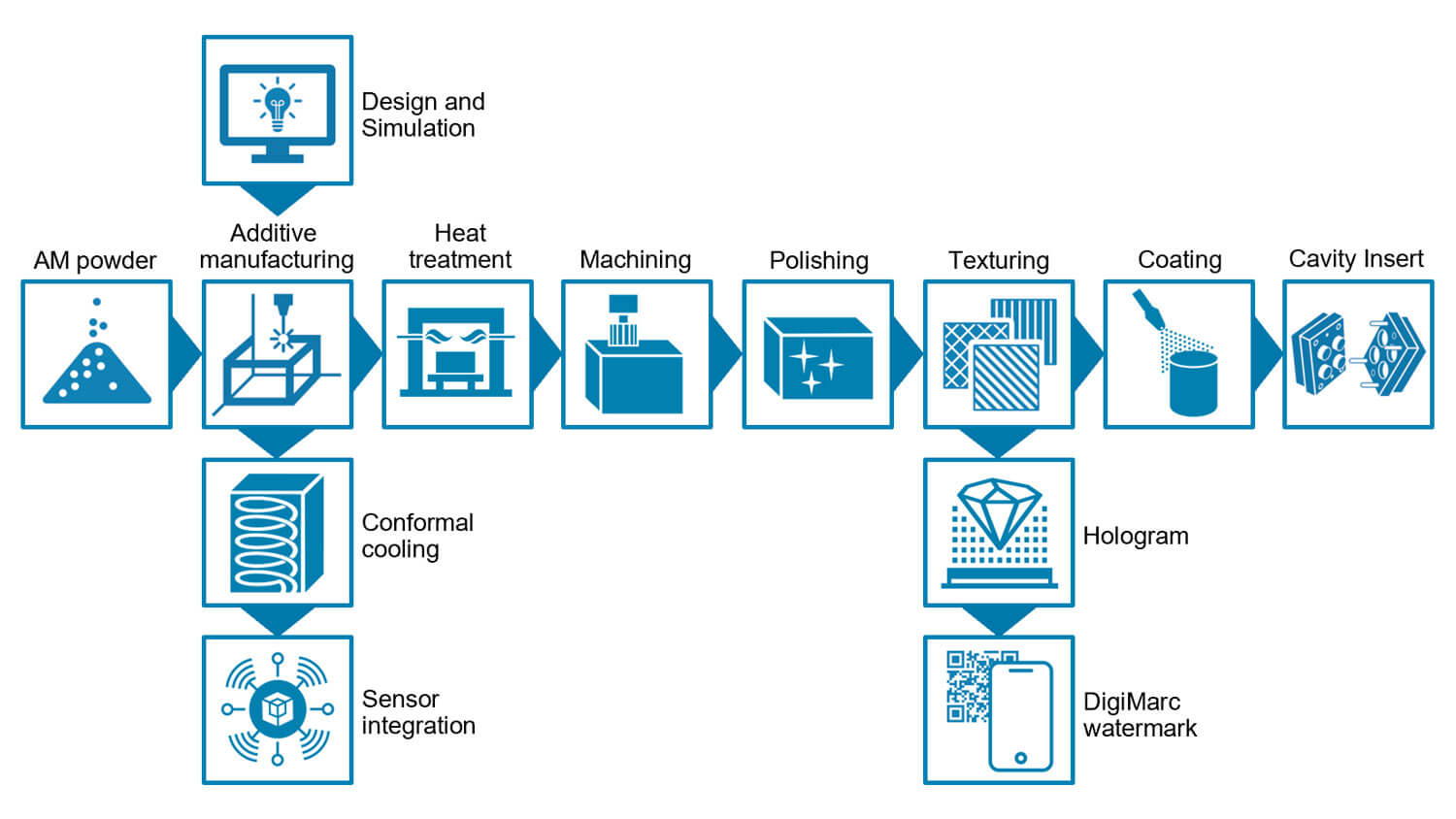

VOESTALPINE CAVITY INSERT VALUE CHAIN

Starting with the selection of the right AM powder and ending with final PVD coating, the voestalpine cavity insert seamless value chain is shown below. The improvements in the injection molding process and in the plastic part quality are achieved through the interaction of the processes and the precise coordination of the individual steps.

Depending on design requirement, all the individual process steps shown above in the value chain are available for the creation of the voestalpine cavity insert. Whether voestalpine HPM customers require only a single process (such as PVD coating) or the entire value chain for a tailor-made solution, they have all the technologies available from the one trusted source.

You can find a comprehensive presentation of all the processes shown in the value chain on our vHPM Germany website here.

For the creation of the cavity insert demonstrated at the Fakuma Trade Fair, the manufacturing process can be summarized as follows:

1. Premium Powders, Additive manufacturing, heat treatment, machining and polishing

Using premium AM powder from BÖHLER / Uddeholm and optimized process parameters, the cavity insert is additively manufactured by the voestalpine Additive Manufacturing center Düsseldorf according to design requirements (including the integration of conformal cooling channels) to meet the highest possible part quality. Post processing begins with optimum heat treatment using a vacuum hardening furnace. The tempered surface allows for mechanical processing (carried out by our project partner FBB Formenbau Buchen GmbH. Subsequent polishing by our experts at voestalpine eifeler Group achieves a high gloss surface finish. The basis for this is the combination of the powders and the optimized AM process parameters.

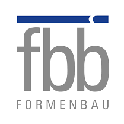

2. Variothermal temperature control and sensor integration (voestalpine Additive Manufacturing Center and Simmo GmbH)

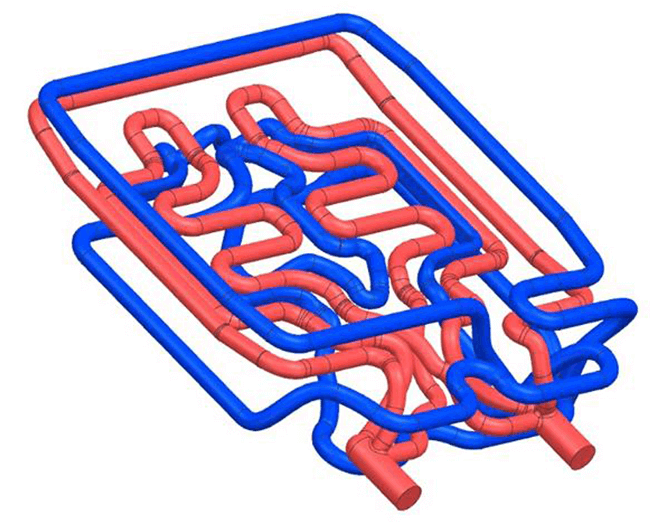

Conventional layout

Conformal layout

The integrated conformal cooling channels follow the intricate cavity wall contours, providing a far more uniform heat extraction compared to conventionally drilled cooling channels. The homogenous temperature distribution within the cavity eliminates hot spots, minimizes thermal stresses, and thereby enables superior part quality (elimination of flow lines) and a reduced cycle time.

The conformal cooling layout in the cavity insert is optimized for variothermal temperature control—with an enlarged heating area and minimized distances between cooling channels and cavity walls. By enabling rapid heating of the cavity walls, flow lines are eliminated from the part surface and fine surface textures (such as the hologram) can be reproducibly incorporated in the plastic part.

Using voestalpine HPM patented technology, two thermocouples are integrated in the cavity insert to allow real-time monitoring as outlined below to ensure part quality and allow optimum switching from heating and cooling.

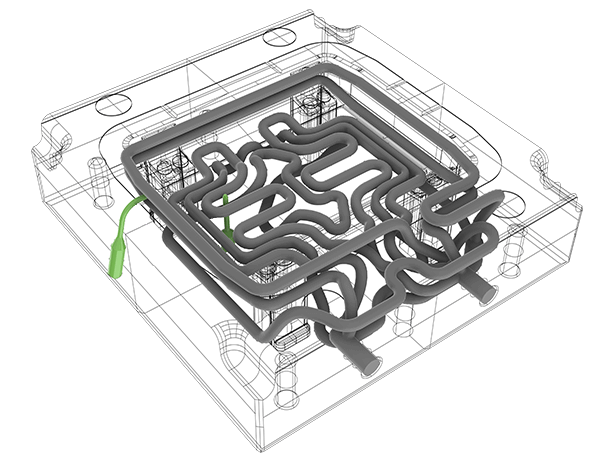

3. Temperature control and sensor monitoring

Two thermocouples integrated in the mold insert

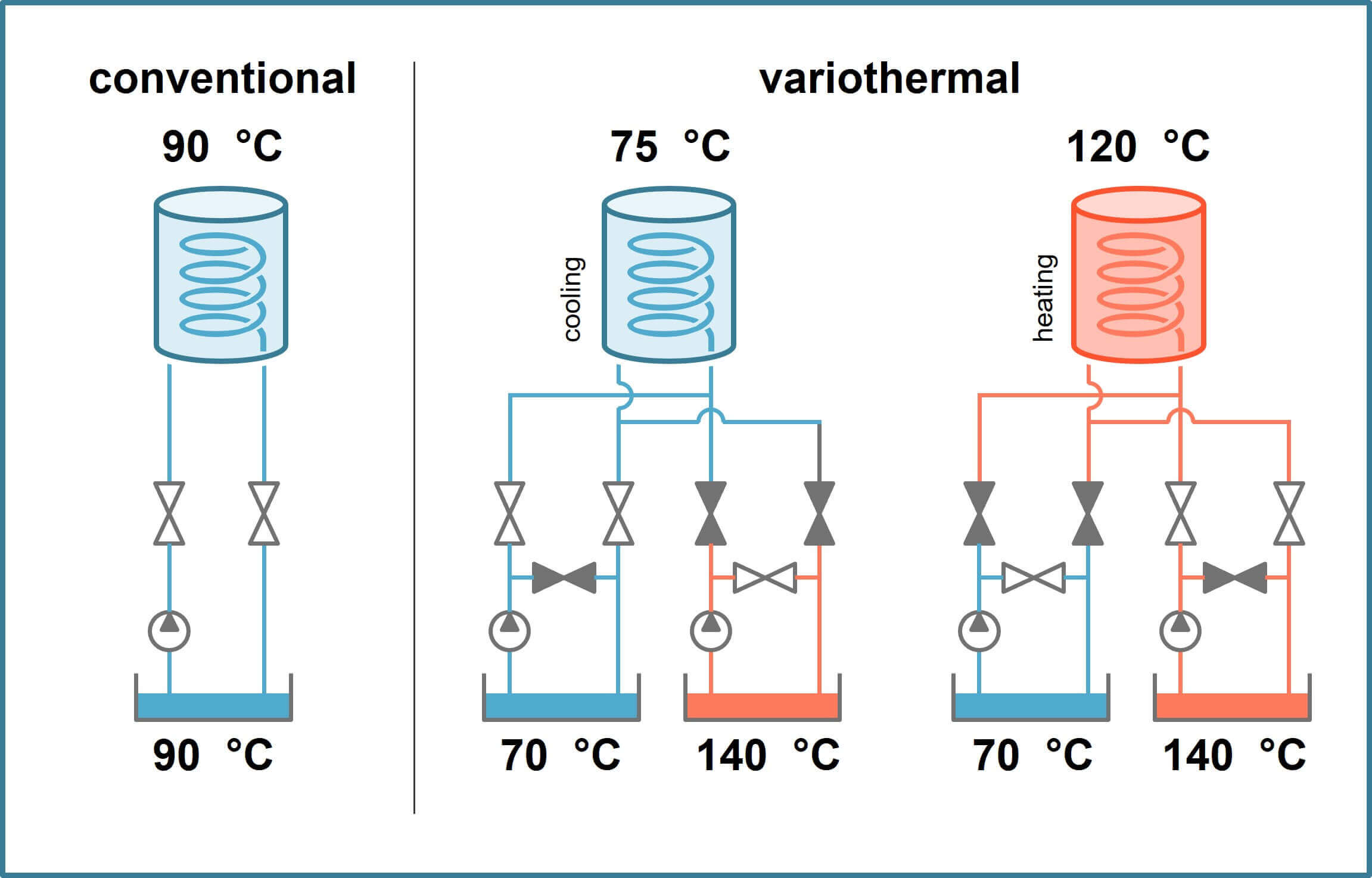

Conventional vs variothermal temperature control

The conformal cooling channel configuration within the cavity insert allows for variothermal temperature control (70/140°C). The increased flow front temperature in the variothermal process eliminates flow lines. Despite the variothermal process control, the cycle time can be reduced by 18% compared to the conventional process (conventionally manufactured insert). The sampling of this process was undertaken by our Partner FBB Formenbau Buchen GmbH.

The two thermocouples integrated in the demonstration cavity insert are shown in green in the image above. One sensor measures the mold wall temperature in the areas of the flow lines; the other sensor measures the area of the hologram structure. These precisely positioned sensors allow real-time measurement of heating and cooling phases, thereby enabling the injection molding process to be optimized for the elimination of defects and a reduction of cycle time. The patented sensor integration process of the voestalpine Additive Manufacturing Center allows the positioning of the thermocouples near to the cavity wall without negatively influencing the cooling channel design.

The data monitoring was supported by our project partner, Kistler Instrumente AG.

4. Texturing and PVD coating

Through the expertise of voestalpine Eschmann Textures, the cavity insert is processed using femto-laser technology to produce a visually appealing surface background texture into which a DigiMarc is integrated. The digital watermark can be used to integrate invisible information into the surface of plastic products.

The use cases of the DigiMarc range from integration of recycling information directly onto the component surface to plagiarism protection. In this case the DigiMarc is used to link to a landing page with additional information about the project.

The femto-laser technology also allows extremely precise fine structures to be engraved into the mold surface, such as the hologram effect (shown above) enhancing the logo: voestalpine – one step ahead.

These fine surface structures use the phenomenon of diffraction, in which light waves hitting the structures spread out instead of being reflected in only one direction. Depending on the position of the observer and the light source, the light is refracted in various spectral colors.

The used polymer – a PC/ABS with additives for flame retardancy and UV-protection – requires protection of the fine texture against wear. Only by the exact interaction of the coating and the texturing in combination with the conformal cooling temperature control and the sensorized process monitoring can the accuracy of the hologram can be maintained over the tool lifetime. The TiN-ultrafine coating of eifeler Coating GmbH enables the required surface quality for the plastic part.

This hologram effect can be molded onto the surface of the part using the injection molding process. Along with a myriad of creative optical applications, the hologram effect can also be used for security purposes.

READY TO INCREASE EFFICENCY AND ADD VALUE TO YOUR INJECTION MOLDING PRODUCTS?

As you have discovered in this article, the voestalpine cavity insert demonstrates a seamless value chain—from concept to finished product. The value chain not only enables improvements to the injection molding process through features such as AM conformal cooling design and variothermal temperature control, but through technologies such as texturing and PVD coating, it also enables value-added product features such as DigiMarc and the hologram effect.

Depending on design requirements, all the processes within the seamless value chain are available to create voestalpine Engineered Products for plastic injection molding. And these very same processes— whether as a single technology such as PVD coating or as a chain of technologies comprising a tailormade solution—are what enable our customers to increase their efficiency and add value to their plastic products.

CONTACT OUR EXPERTS

If you’d like to find out how voestalpine HPM can help your injection molding business, our experts are ready to speak with you. You can contact them below.

WANT TO FIND OUT MORE?

Find out more about the voestalpine cavity insert for an electrical housing by visiting our website in Germany here.

We’re continually expanding our collection of interesting and informative articles about plastic injection molding. Here are a few more articles that might interest you:

Increase profits through voestalpine Engineered Products for plastic injection molding

Read hereYou can read all our articles about voestalpine Engineered Products by visiting our blog here.