MEETING THE HIGHEST REQUIREMENTS FOR PLASTIC HOUSINGS

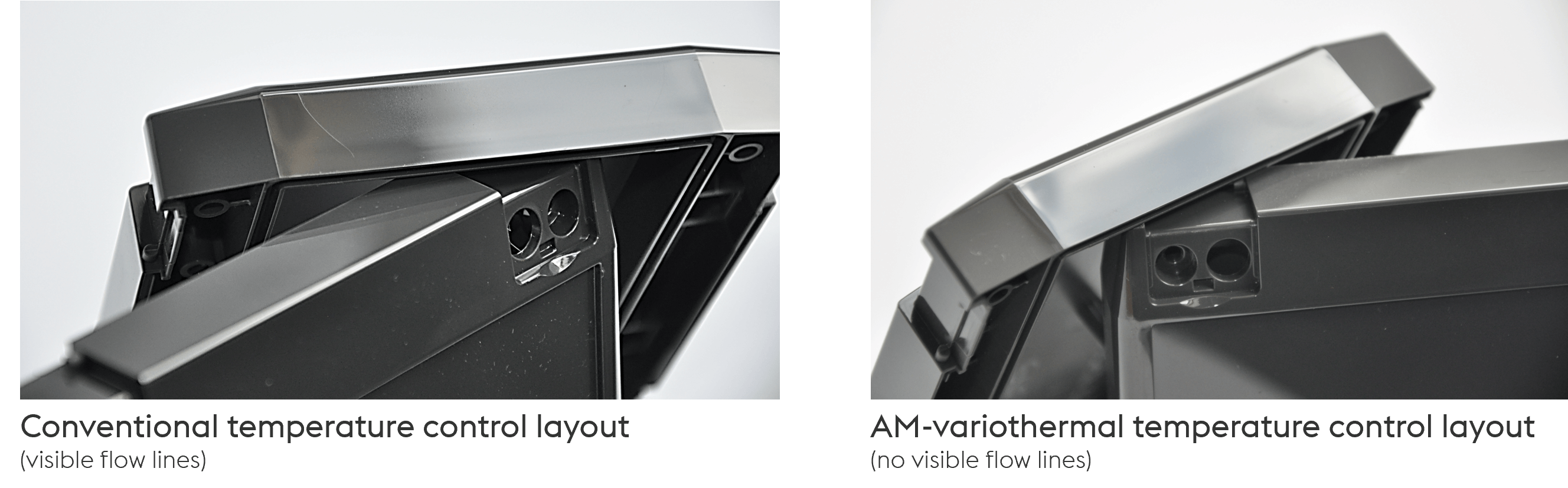

In addition to the technical function of a plastic molded part, aesthetic aspects in particular play a decisive role in the purchase decision nowadays. In the case of housing components – such as this demonstrator – non-optimized thermal management of the mold insert can lead not only to dimensional deviations, but also to visible weld lines and flow lines in the area of functional elements and cutouts. This often results in higher reject rates as well as longer cycle times due to process-related corrective measures.

» Avoidance of visible surface defects through conformal, variothermal process control

Customers often associate quality and durability with the external appearance of a product. Surface textures can convey a certain value and strengthen customer loyalty. In addition to the aesthetic aspects, the finest textures can also increase product protection. In the future, hidden codes in the texture will play an increasingly important role. These codes can not only guarantee counterfeit protection, but also make additional product information accessible to customers.

» Customizable surface design through FEMTO laser technology and integrated product protection through DIGIMARC watermarks

FROM CONCEPT TO PRODUCT - SOLUTIONS FOR PLASTIC INJECTION MOLDING

In the case of highly complex molded parts, meeting the diverse requirements and boundary conditions demands precise interaction and fine-tuning of the individual disciplines. The demonstrator presented illustrates the potential that can be unlocked by combining state-of-the-art design methods, manufacturing technologies and materials.

To learn more, click on the boxes:

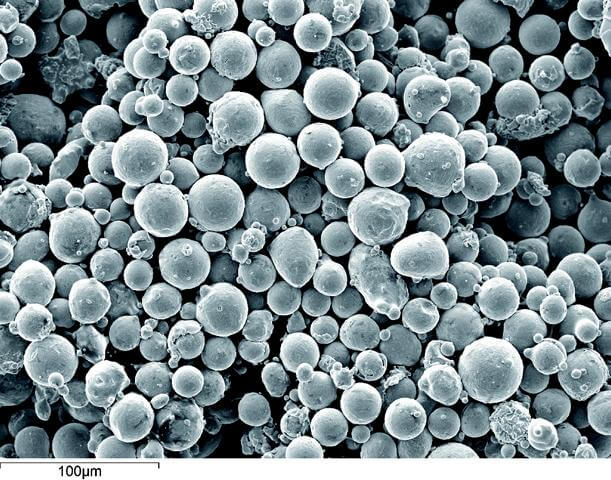

AM-POWDER (premium materials from BOHLER and UDDEHOLM)

Our long history of developing materials for the injection molding industry means that the powders we use are of the highest quality and provide superior tool life. Our AM powders are developed and manufactured by the same experts responsible for our premium tool steels.

| Uddeholm Corrax® for AM and BÖHLER M789 AMPO | Uddeholm Dievar® for AM and BÖHLER W360 AMPO |

|

|

| Material | Achievable hardness | Corrosion resistance | Wear resistance | Polishability | Notch impact energy |

| 1.2083 ESU | 52 HRC | «« | ««« | «««« | / |

| Uddeholm Corrax® for AM | 50 HRC | ««««« | ««« | ««««« | «««« |

| BÖHLER M789 AMPO | 52 HRC | ««««« | ««« | ««««« | «««« |

| 1.2343 ESU | 53 HRC | / | ««« | ««««« | / |

| BÖHLER W722 AMPO (~1.2709) | 54 HRC | / | ««« | «««« | / |

| Uddeholm Dievar® for AM | 48 HRC | / | ««« | ««««« | ««««« |

| BÖHLER W360 AMPO | 57 HRC | / | ««««« | «««« | ««« |

DESIGN AND SIMULATION

Mold design for additive manufacturing and process simulation go hand in hand. Our AM experts generate extensive computer models to help identify potential failure modes and remove these problem areas before they can cause premature tool failure. This process ensures the best possible design solution is adopted before we print the part.

» PEACE OF MIND THROUGH DESIGN OPTIMIZATION

The conventional cooling channel layout requires increased mold temperatures to minimize the visual appearance of weld lines and flow lines. However, this is accompanied by an increase in cycle time and the scrap rate due to visual defects cannot be completely avoided. Using our data-driven approach, we generated a conformal cooling channel layout and optimized it for variothermal process control. Process parameters and mechanical loads were analyzed to create a detailed digital twin of the injection molding process for the housing. Thanks to the optimized temperature control, reject rates were eliminated by avoiding flow lines and surface defects.

» OPTIMIZATION OF THE CONFORMAL COOLING LAYOUT FOR VARIOTHERMAL PROCESSING

CONFORMAL COOLING

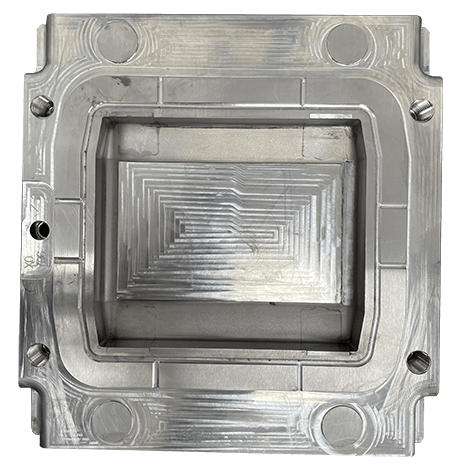

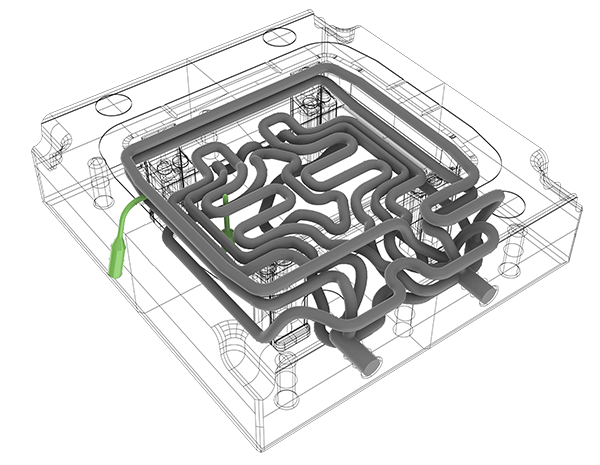

In general, conformal channels follow intricate mold contours, ensuring uniform heat extraction compared to conventionally drilled cooling channels. This consistency guarantees uniform temperatures across the mold, eliminating hot spots and minimizing thermal stresses. Conformal cooling channels have the potential to significantly reduce cooling time, thereby enhancing production efficiency. Additionally, the conformal design enables superior part quality by minimizing warpage and defects.

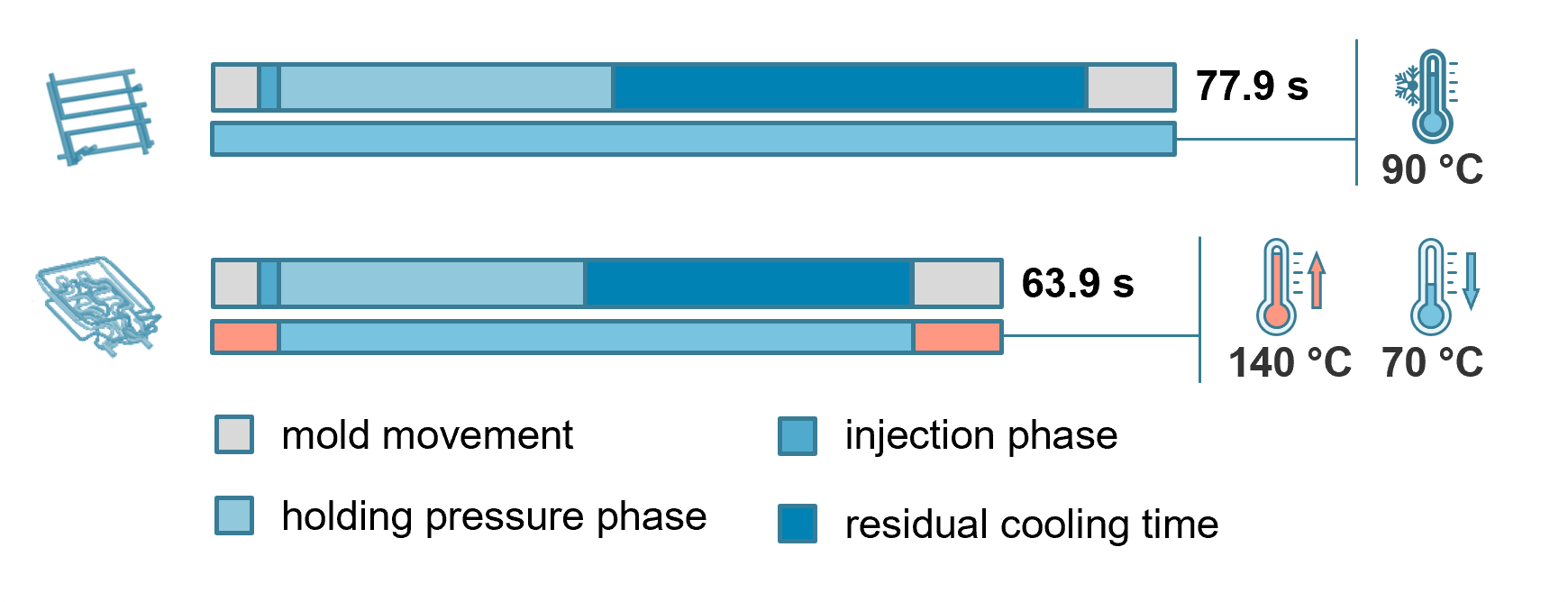

The conformal cooling layout in the demonstrator was optimized for variothermal mold tempering. By enlarging the heating area and minimizing the distance between the cooling channels and the cavity wall, rapid heating of the cavity wall became possible. This eliminated the appearance of flow lines on the part surface and fine surface textures such as holograms. During the holding pressure and cooling phase, the conformal cooling layout facilitated quicker cooling compared to the conventional layout. This made it possible to produce a defect-free part with a shortened cycle time.

Conformal cooling layout in mold insert

Conventional layout

Conformal layout

VARIOTHERMAL MOLD TEMPERING

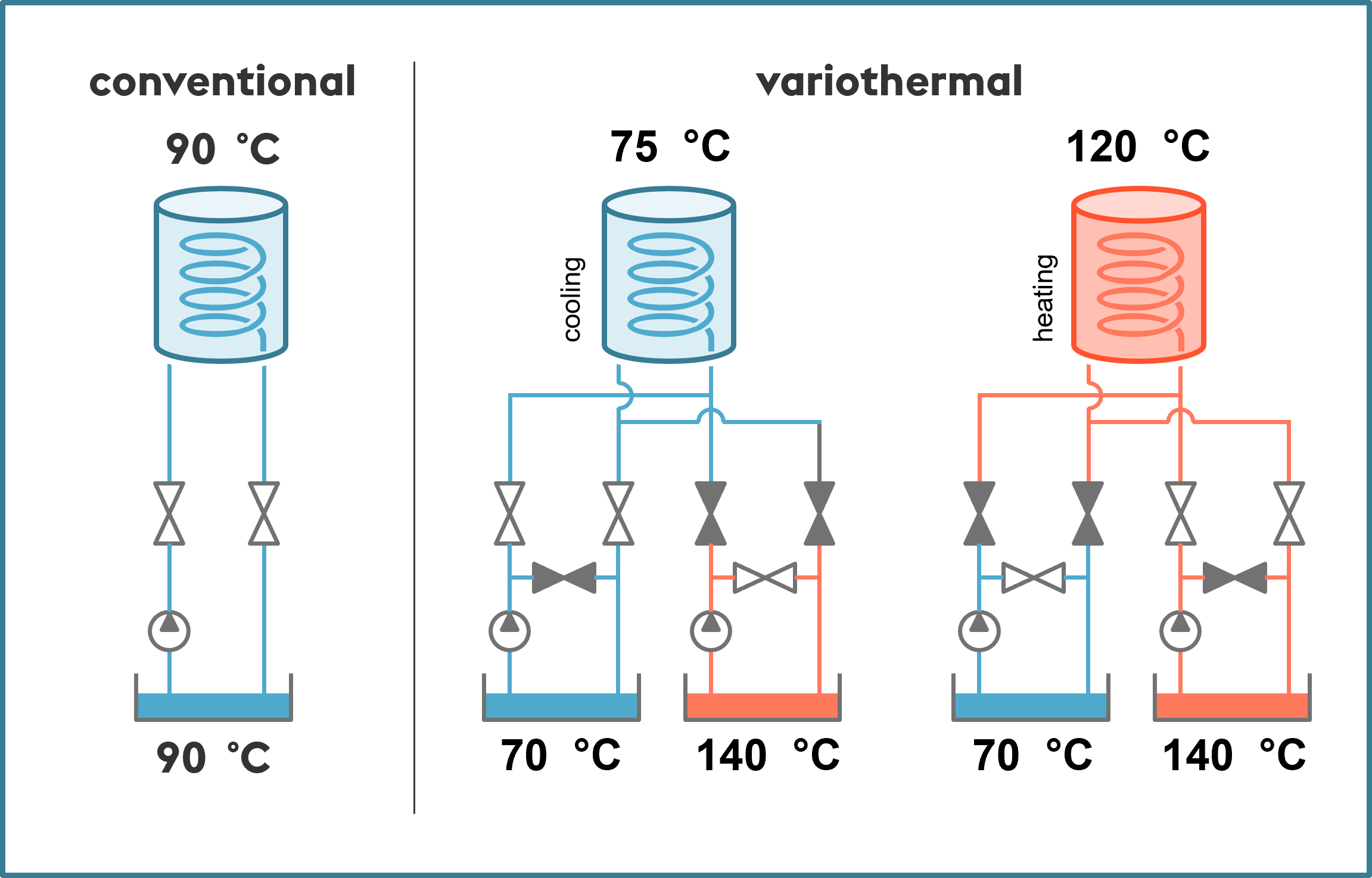

Variothermal temperature control of injection molds improves the aesthetic properties of injection molded structures compared to conventional injection molding by adjusting the mold temperature. In contrast to conventional injection molding processes, in which the molten plastic immediately forms a frozen edge layer on contact with the mold wall, the variothermal process raises the temperature of the mold wall before injection and only cools it down after the filling process. This prevents immediate freezing of the surface layer, improves the gloss level, molds surface structures more precisely and the viscosity remains constant throughout the injection phase. For the economical use of variothermal temperature control, the temperature-controlled mold volume must be kept as low as possible in order to ensure the efficient and rapid supply and removal of heat.

Variothermal and conventional temperature control in comparison

SIMULATION RESULTS

The conformal cooling channel layout in conjunction with variothermal cooling was numerically analyzed in collaboration with our cooperation partner SIMMO GmbH. The great potential of conformal cooling in conjunction with variothermal process control was demonstrated and optimized. At an inlet temperature of 120/60 °C, for example, the mold insert can be heated from 62 °C to 116 °C within 11 seconds.

Part temperature during injection phase - conventional

Part temperature during injection phase - variothermal

position and imprint of weld and melt lines - conventional

position and imprint of weld and melt lines - variothermal

ADDITIVE MANUFACTURING AND HEAT TREATMENT

We ensure the highest possible part quality, reliability and consistency by managing every step of the value chain from powder production to the delivery. Whether for a single part order or series production, our internal quality systems ensure we meet your requirements every time. We use state-of-the-art tools to continually improve and refine our internal printing processes. Design of Experiments, Statistical Process Control, and Process Monitoring form the basis of our methodology. Continued innovation from our AM and materials groups ensures we deliver superior material properties in the most demanding applications. As a result, our customers can put parts into service with the highest degree of confidence.

We understand the interactions between laser and material. This deep understanding of AM and PIM allows customers to add value to their business and realize competitive advantage.

left: De-powdered mold insert

Our post-processing options range from simple separation of the component from the platform to powder removal from cooling channels to the finished and ready-to-install product. Our vacuum hardening shops are equipped with vacuum hardening furnaces of various sizes and thus offer a high degree of flexibility in hardening and tempering. Thanks to the know-how and many years of experience of our specialists, we can ensure optimum heat treatment results and reproducible properties for our additively manufactured components.

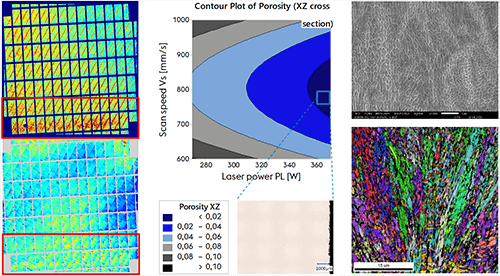

OPTIMIZED PRINTING

We understand the interactions between the additive manufacturing process and the material, and this in-depth understanding enables a process-safe solution as well as pore-free surfaces for the highest part surface quality.

left: Optimization goal „build zone“ detected by process monitoring using EOSTATE Exposure OT (top) and EOSTATEMeltPool (below)

middle: Design of Experiments for paramter optimization using contour map of response surface design for porosity (top) and the related metallographic sample after optimization (below)

right: Microstructure of AM processed H13-type analyzed by SEM (top) and EBSD (below)

MECHANICAL PROCESSING

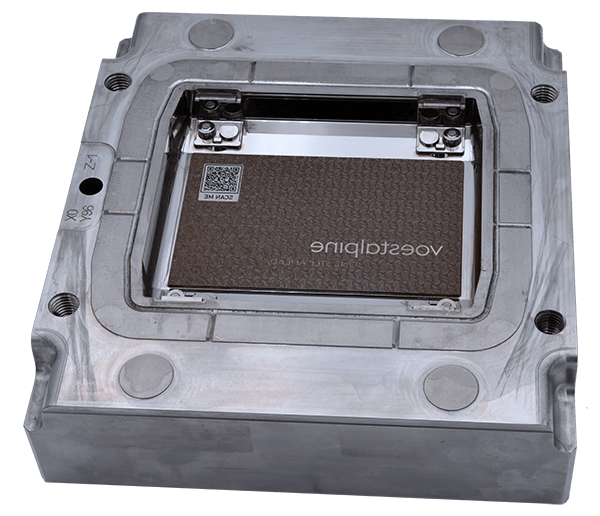

The mechanical processing of the additive manufactured insert was carried out by our cooperation partner FBB Formenbau Buchen GmbH. This forms the basis for all downstream machining steps.

FBB is an experienced expert in the manufacture of plastic and silicone products, developing customized tools and molds that take into account customer requirements and quality standards. Whether for injection molding or silicone injection molding, FBB is your reliable partner for high-quality and functional products in professional and private use.

left: Mold insert after EDM

POLISHABILITY OF ADDITIVE MANUFACTURED MOLD INSERTS

Polishability is a hugely important factor in the plastics injection molding industry. The resulting polishability of additive manufactured mold components depends on a number of factors such as the printing parameters and the quality of the powder. We have optimized our printing and powder manufacturing processes to ensure our printed inserts can be polished to meet SPI industry standards. Through close cooperation between parameter development and our polishing experts at voestalpine eifeler Group, we can guarantee the best polishing quality.

The processing parameters optimized for our own powders ensure that the components are free of pores (density 99.98 %) and enable high-gloss polishing (SPI-A1).

High-gloss polished parts

TEXTURING OF THE MOULD SURFACE

Eschmann Textures offers a wide range of technologies worldwide for the surface treatment of plastic processing molds according to individual customer requirements. Depending on the specific requirements for mold geometry and design, we always provide the appropriate technology for subsequent mold processing. For this purpose, we utilize a diverse production portfolio, which includes high-precision 5-axis laser processing as well as classic etching technology. In this way, we open up new perspectives for plastic molds by realizing appealing visual and haptic surface textures, ranging from automotive applications to lifestyle products.

The mold insert is finished with a background texture into which a digital watermark has been integrated. Thanks to the femto-laser technology used, even the finest structures can be introduced.

DIGIMARC-WATERMARK

Digital watermarks can be used to integrate invisible information into the surface of plastic products. We have integrated the digital watermark into the laser structuring of the housing surface. Possible uses of this technology include efficient tracking of content, increasing consumer interaction and maintaining brand reputation. Furthermore, the technology can gain importance in the future for the integration of recycling information directly into the component surface.

Using the demonstrator as an example, you could follow the watermark directly to this website. For the integration of digital watermarks into tools for plastics processing, Eschmann Textures is your partner.

Link to Digimarc-App

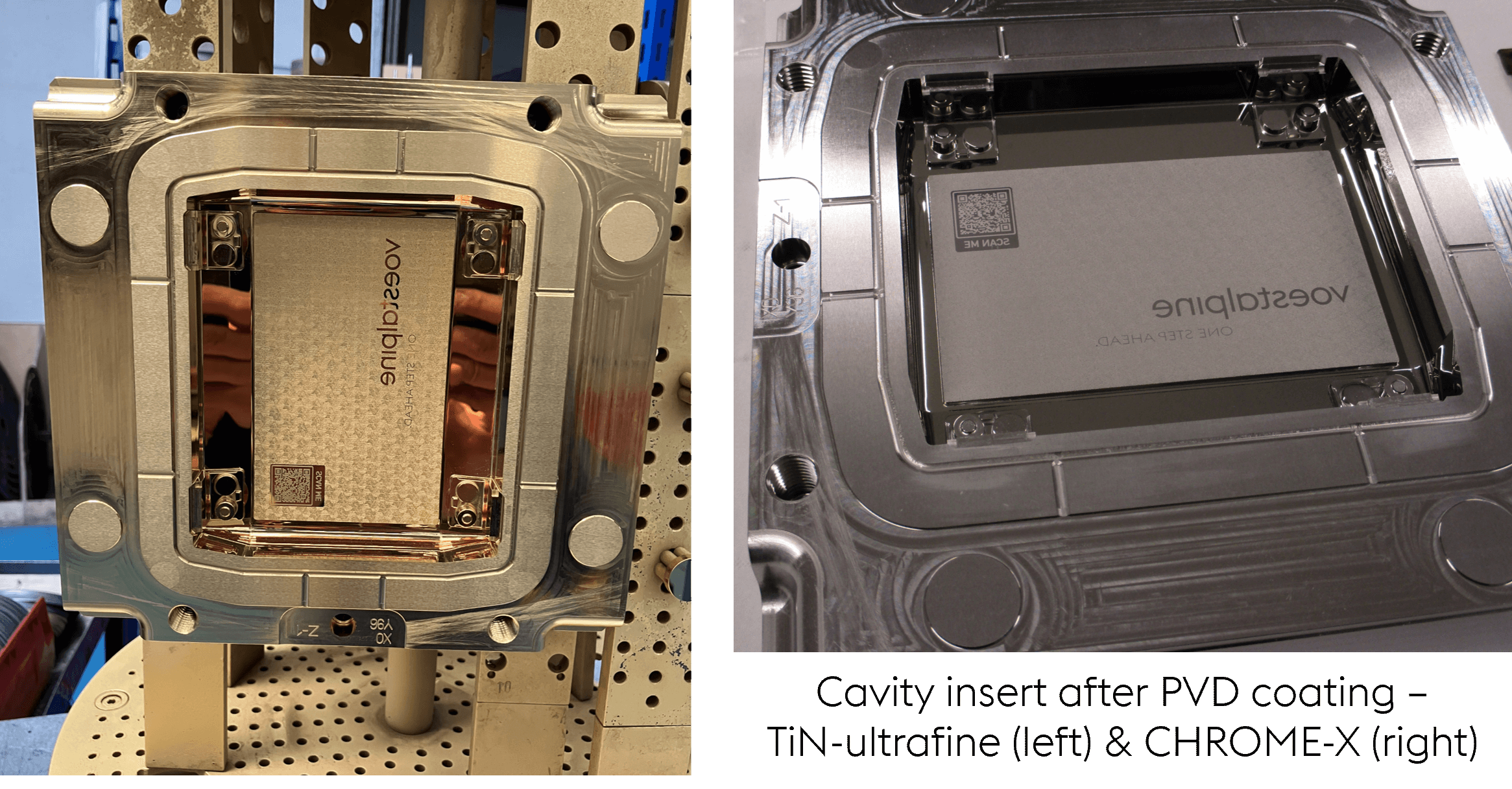

PVD-COATING

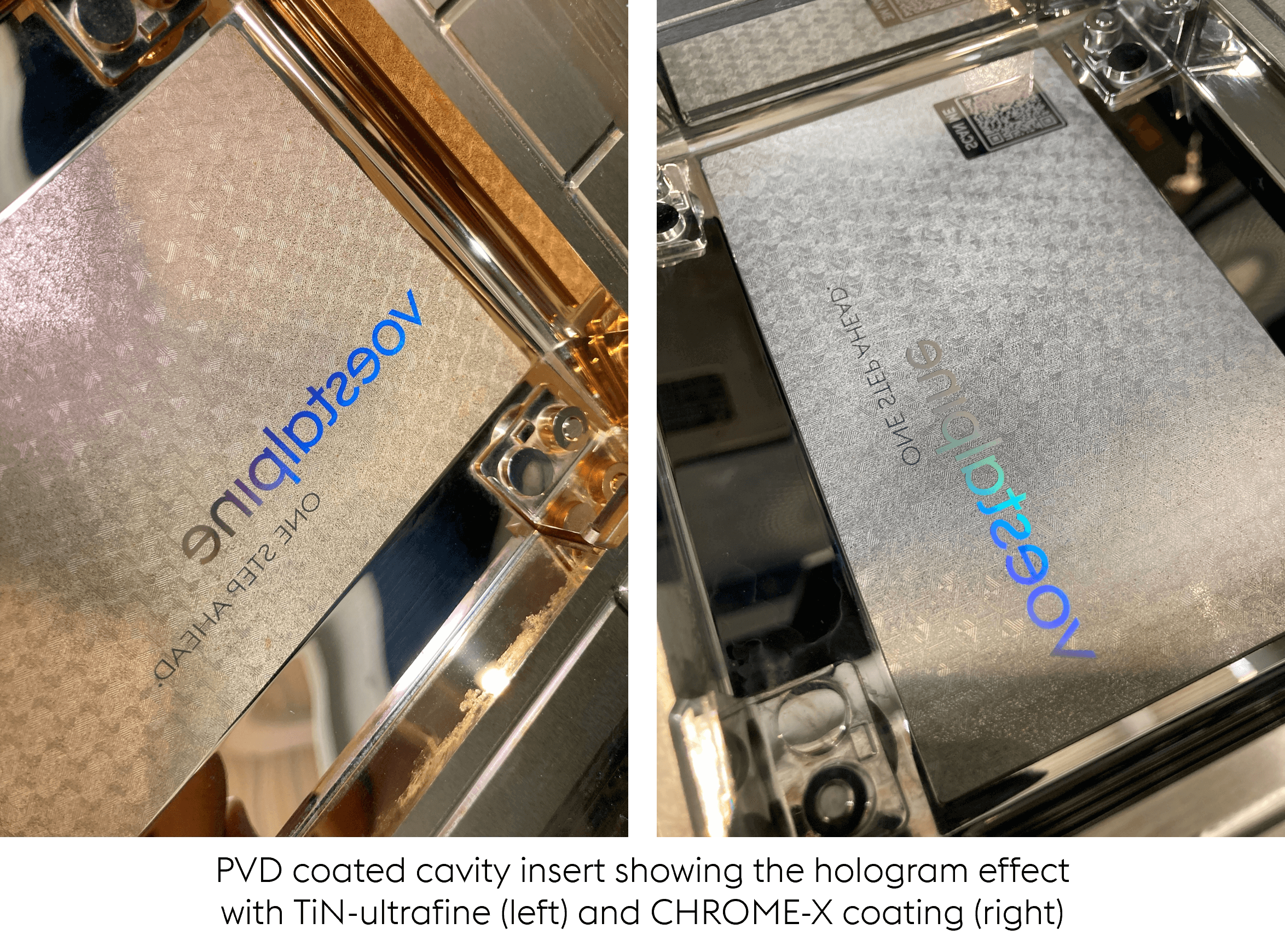

The flame-retardant PC/ABS molding compound used for the housing makes wear protection of the fine hologram texture necessary in order to maintain the effect over the tool life. The required wear resistance of the surfaces while maintaining the high gloss surface is achieved with the TiN-ultrafine or CHROME-X coating from voestalpine eifeler Coating. In addition to wear protection, the coating also has a positive effect on demolding. The TiN-ultrafine is a wear-resistant Arc-coating that is produced using SPCS technology and therefore has fewer droplets than the conventional Arc-TiN-coating. In contrast, CHROME-X uses sputtering technology, which enables droplet-free application. TiN-ultrafine or CHROME-X can therefore be used to achieve the ideal compromise between wear resistance and gloss preservation.

With its advanced services, technologies and products, voestalpine eifeler Coating has been offering targeted adjustments to surface properties for over 40 years, thereby enabling the optimization of manufacturing processes and mold properties. The right product solution for the respective customer application reduces wear and increases the service life of molds and components.

HOLOGRAM

Our femto-laser technology allows extremely precise fine structures to be engraved into cavity inserts, such as hologram effects that back the logo „voestalpine – ONE STEP AHEAD.“. These structures use the phenomenon of diffraction, in which light waves hitting the structure spread out instead of being reflected in only one direction. Depending on the position of the observer and the light source, the light is refracted in various spectral colors. This effect can be controlled by laser parameters.

The hologram-effect can be molded onto the surface of the part using the injection molding process and not only serves an optical purpose but can also be used for security applications.

INJECTION MOLDING

The mold insert was sampled by the cooperation partner FBB Formenbau Buchen GmbH. Both the conventionally drilled insert with continuous water tempering (90 °C) and the additively manufactured insert with conformal, variothermal tempering (70/140 °C) were sampled. The increased flow front temperature in the variothermal process completely eliminated flow lines. The conformal cooling channel layout allowed rapid heating of the mold insert to the target temperature of 120 °C. This made it possible to achieve heating during secondary times. The lower mold temperature in the holding pressure phase and residual cooling time enabled the cycle time to be reduced by 18 %.

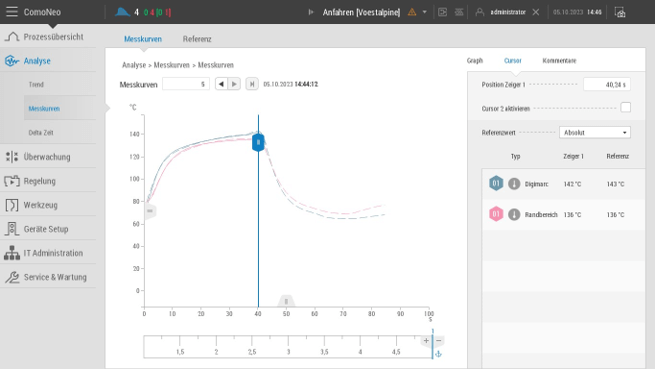

SENSOR INTEGRATION

Our patented technology for integrating thermocouples into additively manufactured mold inserts enables extremely precise placement of the measuring points directly below the mold wall. In doing so, we use the greater design freedom of additive manufacturing for the integration of the sensors without affecting the layout of the tempering channels. The application possibilities of this technology are numerous. They range from monitoring the mold temperature to analyzing the functioning of cooling channels over a certain period of time. In addition, potential faults in the temperature control can be detected. In this demonstrator, variothermal process control is quantitatively recorded. Process monitoring systems such as the ComoNeo from our cooperation partner, the Kistler Group, can be used to perform these tasks.

Two thermocouples are integrated in the demonstrator shown. One sensor measures the mold wall temperature in the area of the flow line, the other in the area of the hologram structure. With the help of these sensors, the heating and cooling phases in the areas of the flow line formation and the hologram structure could be quantitatively captured. This provided insights into the process that can be used to both improve part quality and optimize cycle time. Due to the precise positioning of the thermocouples, the heating and cooling phases could be measured without any time delay compared to the measurement of the backflow temperature. This enabled the variothermal injection molding process to be optimized efficiently in terms of cycle time.

FULL ELIMINATION OF SURFACE DEFECTS