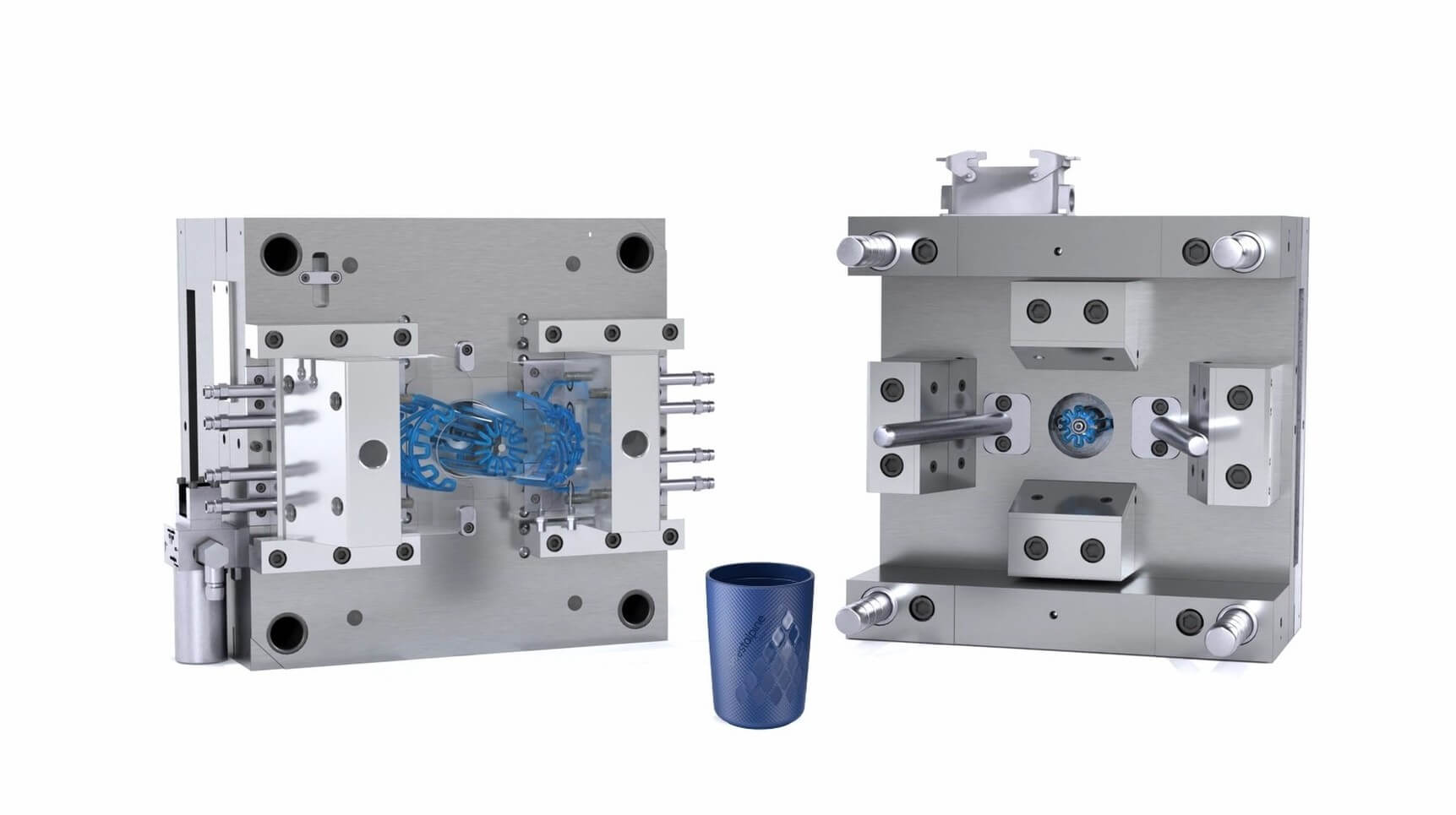

Coffee cup and lid mold video: End-to-end innovation for plastic injection molding

We’re pleased to release our new video featuring the voestalpine Coffee Cup and Lid Molds—a technology carrier that demonstrates how our High Performance Metals Division helps injection molders and tool makers unlock productivity, part quality, and design freedom.

In the video, you’ll see how we support customers across the entire value chain for plastic injection molding solutions:

- Design & Engineering—Simulation‑driven, application‑specific design with conformal cooling technology, sensor integration, and weight reduction built in from the start.

- Additive Manufacturing for Molds—Premium BÖHLER/Uddeholm tool‑steel powders and optimized heat treatment deliver parts with densities up to 99.997%, enabling high performance and high‑gloss polishability.

- Machining & Polishing—Precise downstream processing ensures bar‑stock‑comparable mechanical properties and flawless surface finish.

- Laser Texturing and PVD Coating—Eschmann Textures applies ultra‑short pulse (femto) laser technology to achieve visually and haptically refined surfaces and functional microstructures, while voestalpine eifeler Coating enhances wear resistance and tool longevity.

By integrating these steps early in the mold design, the voestalpine Coffee Cup Mold demonstrates shorter cycle times, tighter dimensional control, and superior microstructure molding—from concept to ready‑to‑use cavity inserts.

Watch the video and explore the details here:

Find out more

Find out more about the Use Case: voestalpine Coffee Cup and Lid Molds here.

Talk with our experts

Our experts are ready to help you explore new possibilities in mold and part design.