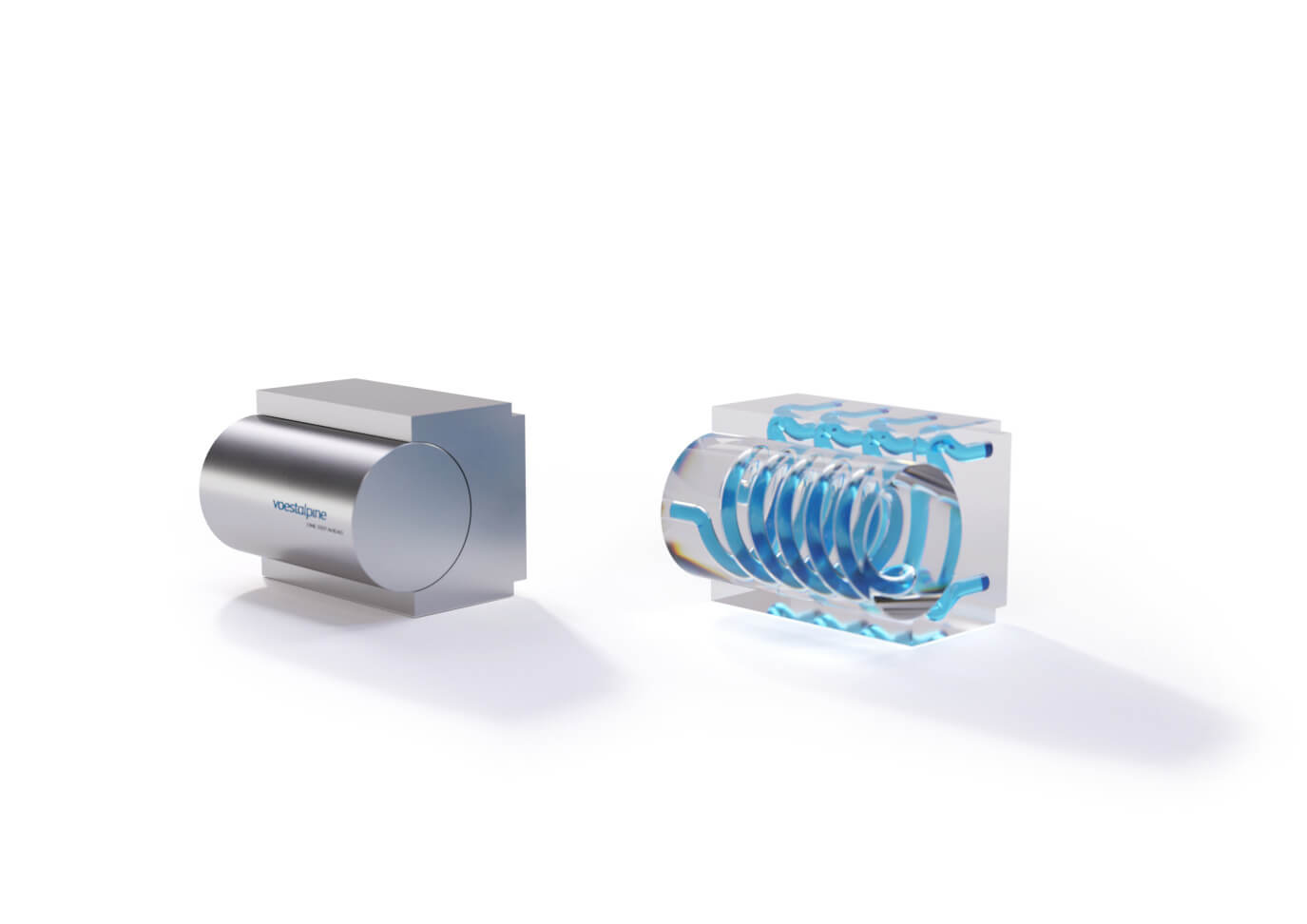

voestalpine Inserts for Cylindrical Containers

designed for pure performance

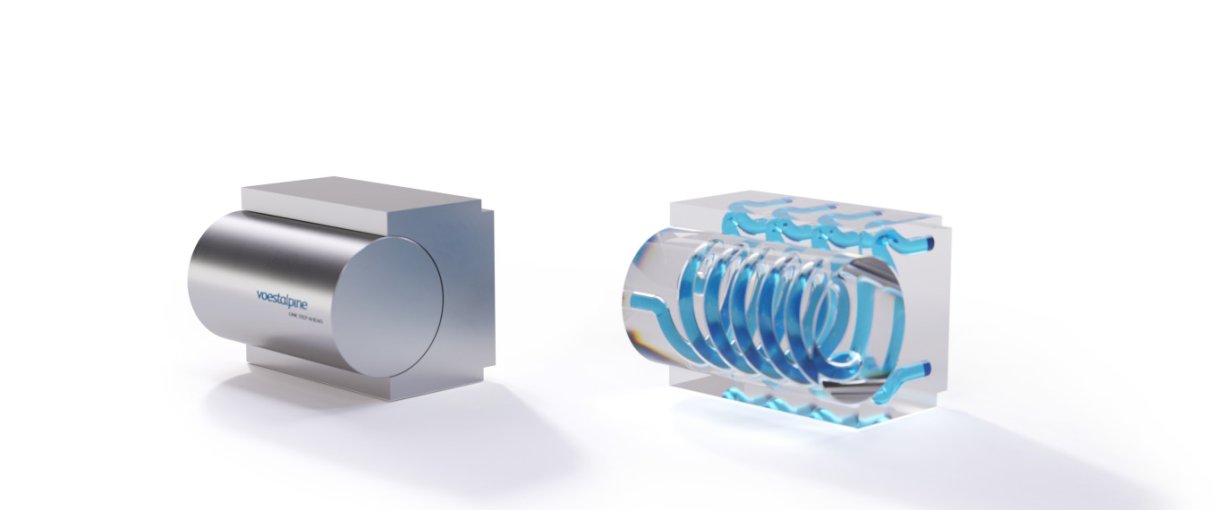

voestalpine Inserts for Cylindrical Containers are produced using additive manufacturing and have optimized conformal cooling channels that enable our customers to run a stable and highly efficient production. This results in a cost reduction per plastic part produced.

Our inserts for cylindrical containers offer an overall cycle time reduction of up to 26% compared to conventionally manufactured inserts. Improved part tolerances are also achieved through homogeneous and conformal cooling design, leading to lower scrap rates and increased productivity. The inserts are highly polishable, highly ductile (safety against cracks), and have high wear- and corrosion resistance.

Many globally active plastic injection molding companies in various industries have confirmed the premium functionality and profitability of our corrosion-resistant inserts for cylindrical containers.