voestalpine HPM tooling solutions increase performance and reduce carbon emissions

Wherever your manufacturing business lies in the value chain, your ability to increase productivity and reduce carbon emissions are key competitive factors. In this article, we share a recent case study showing how one of our customers in the automotive industry addressed these factors by using a voestalpine Sub Insert in their high pressure die casting operation. By partnering with voestalpine High Performance Metals to develop an innovative tooling solution, they were able to keep one step ahead. Read on to discover how they did this and how your business can do the same.

We also share background information about the case study, touching briefly on climate impact, scope 1,2, and 3 emissions from a foundry’s perspective, and the advantage of additive manufacturing (AM) in relation to increased performance and reduced carbon emissions.

CASE STUDY BACKGROUND

CLIMATE PROTECTION CONCERNS US ALL

Climate protection concerns us all. As a global company, we see it as our duty to seize opportunities to make our business as climate friendly as possible. Our sustainability framework inSPire leads the way to ensure long-lasting performance for current and future generations. Developing solutions together with a network of experts and our customers is a good way to jointly promote sustainability in the industry.

You can learn more about climate impact and the definition of GHG Scope 1, 2 and 3 emissions by referring to our recent article “Climate Impact at HPM: Our contribution to climate protection”

SCOPE 1,2, AND 3 EMISSIONS FROM A FOUNDRY’S PERSPECTIVE

voestalpine High Performance Metals has been working hard for years to reduce our carbon footprint, for example, by increasing energy efficiency in our operations, using energy from renewable sources, as well as closing scrap cycles with our production mills. Our ambitious roadmap envisages a 50% reduction in our Scope 1 and 2 emissions in 2029 compared with the base year 2019. We have also committed to supporting our customers in achieving their decarbonization goals. By delivering on the above-outlined ambitions, our customers benefit from products and services with a lower carbon footprint impacting their Scope 3 emissions.

Our case study below provides a good example of how we helped one of our customers substantially reduce their energy consumption and related Scope 1 and 2 carbon emissions in their die casting cell.

THE ADDITIVE MANUFACTURING ADVANTAGE

The demand for performance has always driven the development of voestalpine Engineered Products. Regardless of the market segment in which these ready-to-use products are aligned—including High Pressure Die Casting (HPDC), Plastic Injection Molding, and Food Processing —all have made use of innovative design and manufacturing techniques such as additive manufacturing (AM).

AM offers the design freedom to create conformal cooling channels on any complex shape, thereby providing homogenous cooling and enabling increased productivity. Similarly, channels can be created for sensorized inserts to provide real-time monitoring of production and aimed at increasing efficiency and part quality.

These AM advantages enable our customers to increase their manufacturing productivity, often measured according to the following indicators:

- Reduced scrap rate

- Optimized cycle times

- Reduced maintenance effort

- Reduced downtime

- Extended tool lifetime

Altogether these advantages result in increased overall equipment effectiveness (OEE) for the tool user.

But with voestalpine’s commitment to sustainability, another key performance indicator is the carbon emissions resulting from the production and use of a voestalpine Engineered Product. The optimal outcome:

Performance + sustainability = superior tooling solutions

Dr. Armin Wiedenegger shares his insight into decarbonization in the manufacturing value chain:

Dr. Armin Wiednegger

Managing Director of voestalpine Additive Manufacturing Center Düsseldorf

Major players in the automotive industry have embarked upon the path of decarbonization. This has significant consequences: We see the emerging requirements for transparency on the product carbon footprint, and we expect that the demand to reduce emissions will be pushed back towards suppliers in the value chain. Solutions that support this development are needed—and voestalpine HPM already offers them.

CASE STUDY: DOES AN AM SOLUTION ENABLE INCREASED PERFORMANCE AND A REDUCTION OF CARBON EMISSIONS?

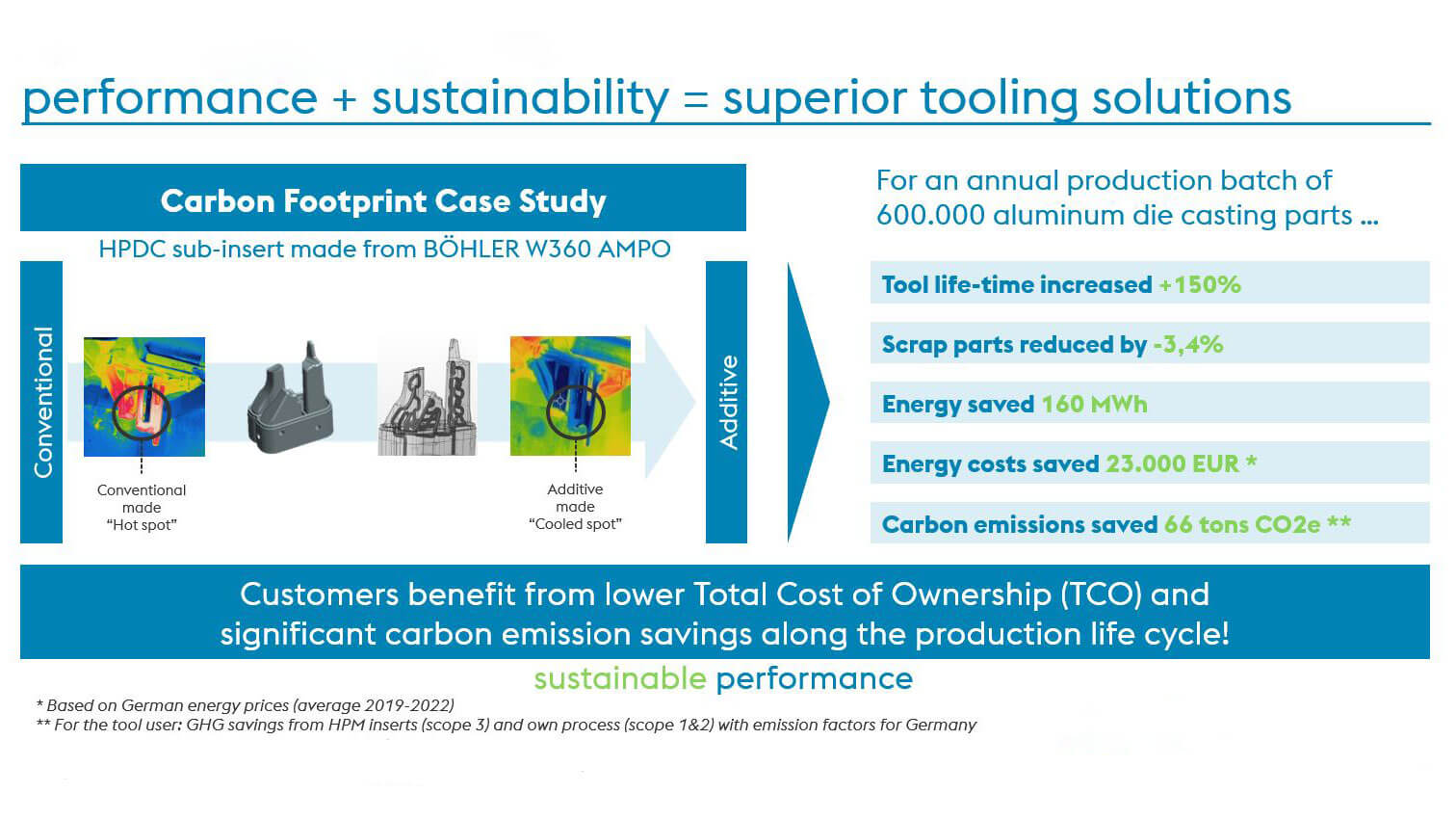

The aim of our case study was to compare the performance and carbon footprint of a conventionally manufactured sub insert with a voestalpine AM Sub Insert in both their production and use phase.

Key case study data:

| Application: | High pressure die casting (HPDC) sub-insert |

| Customer part: | Automotive |

| AM powder: | BÖHLER W360 AMPO |

| Powder manufacturer: | voestalpine BÖHLER Edelstahl |

| Part designer: | voestalpine Additive Manufacturing Center, Düsseldorf |

| Printing center: | voestalpine Additive Manufacturing Center, Düsseldorf |

The testing for the case study was undertaken at our customer’s die casting operations in Germany. Both sub inserts (conventionally manufactured and AM) were used by our customer in their HPDC tool to cast aluminum parts for the automotive industry. Due to the high thermal loads and extremely hot temperatures exerted on these sub inserts, they are one of the most critical components in HPDC.

The voestalpine AM Sub Insert was 3D-printed using our premium metal powder BÖHLER W360 AMPO in our Additive Manufacturing Center in Düsseldorf, Germany. Post-processing technologies included heat treatment and machining. In addition to the key data above, you can find out more about voestalpine AM Sub Inserts here.

TEST RESULTS

Based upon the testing in production, we were able to extrapolate results for an annual production batch of 600,000 aluminum parts. As shown in the figure below, the voestalpine AM Sub Inserts provide a significant increase in performance (+150% tool lifetime increase), a substantial reduction of carbon emissions (66 tons CO2e in total), and an annual energy cost saving of 23,000 EUR. The customer also benefits from a reduction in the total tool costs for the sub inserts as a result of the reduced number of sub inserts required (10 instead of 25) to complete the full production batch.

We can also present the test results in relation to the energy and carbon emissions along the tool life—from sub insert manufacturing to its use phase, covering Scope 1, 2, and 3 emissions as described earlier in this article.

As shown in the figure above, the voestalpine AM Sub Insert produces less CO2 to manufacture and less CO2 in its use phase. Key points:

- The single AM Sub Insert saves 74kg CO2e (-21%) compared to the conventional tool manufacturing process. This is due to the world-class powder manufacturing capabilities at voestalpine BÖHLER Edelstahl and significantly reduced material losses (better “buy-to-fly” ratio) from the AM process

- For the customer’s production batch of 600,000 parts / year the following savings could be achieved:

- ~6 tons CO2e in the tool manufacturing process due to the combined benefit of emissions saved for each individual AM Sub Insert and a reduced number of total inserts needed due to the extended sub insert life (only 10 inserts to meet annual batch demand as opposed to 25 conventionally manufactured sub-inserts

- ~60 tons CO2e during the use phase due to a significant scrap reduction (-3,4%) in the die casting cell and post-processing

The use phase (by our customer) represents the greatest reduction of carbon emissions and energy costs. And through savings in both the manufacturing and use phase, our customer benefits from a lower total cost of ownership (TCO) and significant carbon emission saving of 66 tons CO2e along the production lifecycle.

SO, DO VOESTALPINE SUB INSERTS ENABLE INCREASED PERFORMANCE AND A REDUCTION OF CARBON EMISSIONS?

The test results show that the answer is clearly, “Yes!”

But what are the wider implications of this case study? Just how important is it for businesses in the HPDC industry to consider both performance and carbon emissions in production now and in the future?

Philipp Aggarwal, Sustainability Lead for Value Added Services, is convinced about the future potential:

We believe sustainability is becoming an increasingly decisive factor in our key industries. At the same time, we understand that economic criteria remain dominant. By adopting a holistic, product-life-cycle perspective, we see that both ecological and economic criteria can be satisfied. Using the right partner, collaboration and tailor-made solutions are the key. The result is clearly win-win

The anticipated trend towards large castings along with an increasing proportion of casted aluminum per vehicle produced implies growth opportunities for the HPDC industry. Enabling this development in an economically and ecologically viable way may become a source of competitive advantage.

IS YOUR HPDC OPERATION READY TO TAKE ADVANTAGE OF VOESTALPINE HPM TOOLING SOLUTIONS?

As we have shown in this HPDC case study, by using voestalpine AM Sub Inserts, our customer was able to significantly increase their production performance and reduce their carbon emissions. In doing so, they put themselves one step ahead, favorably positioning their business as the tool user of preferred choice in the value chain.

Every day voestalpine HPM continues to develop our Engineered Products and work with our customers in various segments, including HPDC, to provide them with performance-enhancing solutions that can be measured in both economic and ecological terms. If you would like to find out how voestalpine HPM can help your business get one step ahead, our experts are ready to speak with you. You can contact them below: