Revolution of the skip container.

alform® makes many things lighter. The thermomechanically rolled (TM) material combines lightness with stability like no other, making it the perfect candidate for countless applications where high load capacity and low weight are essential. This applies to high-tech and complex machinery as well as comparatively simple containers.

Skips are among the most frequently used containers. It may seem a simple task to carry a maximum-capacity load, but the advantages of lightweight skips are many-faceted. Skip containers can be parked most anywhere at any time and their design can be flexibly adapted to their specific loads and loading requirements. The transportability of skips is not complicated at all. They are indispensable in the world of transport,

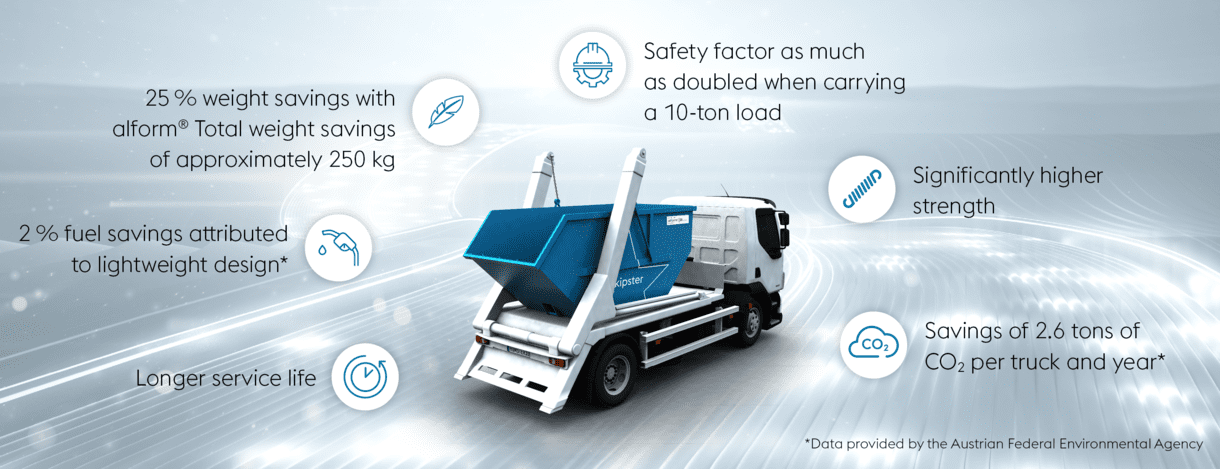

and these fundamental advantages have now been fully integrated by voestalpine using high-tech materials and intelligent design. A revolutionary skip container is the result. At maximum load, it is approximately 25 % lighter and significantly more stable than any other skip container on the market.

25% lighter

When made with alform®, the skipster weighs roughly 25 % less than conventional skipster containers with the same volume. The weight reduction results from the special stability of alform® steels that allow reduced material thickness in the skipster container design without impairing stability. The light weight and maximum load-bearing capacity of the skipster container make it more cost-effective than conventional products, especially in long-term use.

Maximum loads

The enormous stability of alform® becomes very evident when the material is subjected to maximum stress. When compared to conventional containers, the skip provides a significantly higher level of safety at maximum load. Though the wall thickness is substantially reduced, the material effortlessly withstands loads at the upper weight limit. This means that the skip volume can be utilized to full capacity.

Efficient

Material processability plays a major role in the production of skips. High-quality properties are particularly required during the welding and edging processes. The steels of the alform® series perfectly meet these requirements. The fine-grained microstructure ensures excellent formability, while the low carbon content combined with a temper-resistant material design results in excellent weldability.

Material | Hanging load 1 ton/m³ hydrostatic load | Tilted load 1 ton/m³ hydrostatic load | Containers Weight | ||||

Tension stress | Sag | Tension stress | Sag | ||||

abs. [MPa] | Safety | [mm] | abs. [MPa] | Safety | [mm] | [kg] | |

| S235 | 214 | 1.10 | 30.6 | 327 | 0.71 | 17.7 | 929 |

alform 700 | 513 | 1.37 | 48.0 | 444 | 1.60 | 29.8 | 678 |

Maximum values of an open, asymmetrical ten-cubic-meter skipster container. | |||||||