Less weight, more freight: Setting new standards with higher productivity and efficiency

Rail Cargo Group (RCG) was looking for a lightweight design that would meet the logistics requirements of the 21st century. RCG, a subsidiary of ÖBB, has many years of valuable experience in freight transports and is part of a very strong international network. TransANT was jointly developed using the material expertise of voestalpine. With the new TransANT flatbed railcar design, RCG and voestalpine are setting a new standard in the freight transport market and are adapting transport solutions to specific market demands and customer requirements.

Benefits at a glance

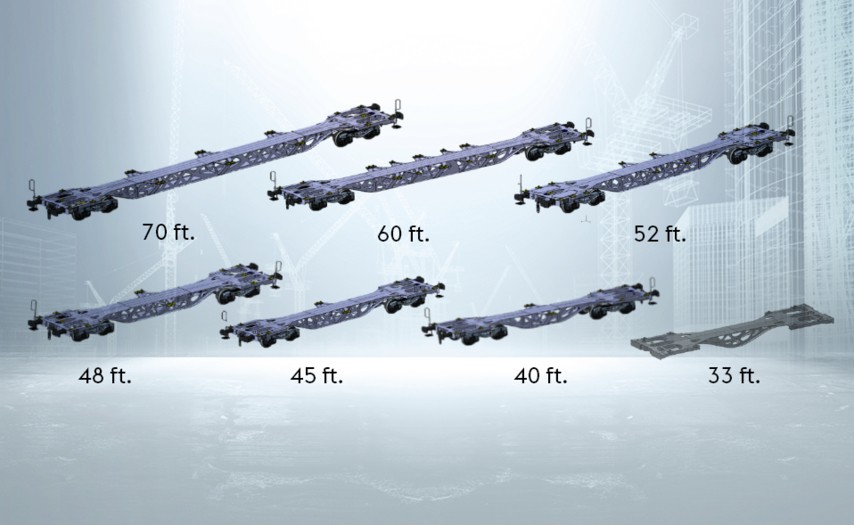

Markets demand modular lightweight designs that can be used universally in the transport sector. This innovation is approximately twenty percent lighter than standard freight cars, thus resulting in a significant payload advantage, even when a superstructure is added. The standardized flatbed is also available in different lengths ranging between 33 and 70 feet, and the modular structures are available in various industry-specific versions. The exchangeable structures make it possible to quickly adapt to changes in logistics requirements.

Design freeze in the railcar family

Improved loading and unloading possibilities coupled with integrated load securing systems optimize the handling and security of transported goods. Superstructures can be used on the TransANT without any restrictions in conventional single-railcar transports. The intelligent interface between superstructure and flatbed enables use in classification yards, and the flatbed can be used to carry transport containers in intermodal transports without any additional superstructure. The railcar features automatic coupling, thus ensuring optimized and automated railway operations.

All-in-one lightweight solutions

A pioneer in the field of ultra-high-strength lightweight components, voestalpine is particularly popular in the automotive sector. The TransANT project has now for the first time made it possible for voestalpine to transfer this expertise to the railway sector. High-strength alform® steels and cut shapes from the Steel Division, welding consumables from the voestalpine Böhler Welding Group and high-strength sections from Krems are used in the innovative flatbed railcar. All of these materials make a significant contribution to weight reduction and versatility.

From innovation to the brand name

The advantages of the TransANT are reminiscent of the special abilities of animals in nature, particularly those of the extremely powerful ant. Ants are flexible, strong, organized, social, adaptable, hardworking and very persistent. These attributes perfectly match the benefits of the innovative railcar of RCG. Ants can lift many times their own body weight, and this idea was integrated into the design.

Product launch in Linz

Wolfgang Mitterdorfer, member of the Management Board in the voestalpine Steel Division, and RCG board members Clemens Först and Thomas Kargl introduced TransANT to roughly 100 interested customers, trade journalists and partners at the exclusive pre-launch event at voestalpine in Linz. The platform railcar was also presented at the Innotrans trade fair in Berlin between 18 and 21 September.