Technology -

Made in United States

The engineering staff of voestalpine Precision Strip WI in our site in Wisconsin has a combined more than 60 years of experience in the special niche of the precision strip steel industry, especially in the field of hardened and tempered products.

Hardening and Tempering

of Steel Strip

Simply put, hardening & tempering is the process of transforming cold-rolled steel into high-strength spring steel through a series of heat-treating operations. These operations are performed at voestalpine Precision Strip WI in Pleasant Priarie in state-of-the-art, continuous heat-treating furnaces manufactured by EBNER, Austria - the universally acknowledged world-wide leading manufacturer of such facilities.

The design and execution of these furnaces enables us hardening & tempering a range of high-carbon and alloyed strip grades to exacting tolerances with respect to both geometrical and mechanical properties. The technology also allows a range of material microstructures from a fully bainitic structure through a fully martensitic structure.

Range of dimension

The design and execution of these furnaces enables us hardening & tempering a range of high-carbon and alloyed strip grades to exacting tolerances with respect to both geometrical and mechanical properties. The technology also allows a range of material microstructures from a fully bainitic structure through a fully martensitic structure.

Range of dimension

| inch | mm | |

| Width range | 0.250" - 25.000" | 6,35mm - 635,00mm |

| Thickness Range | 0.004" - 0.094" | 0,10mm - 2,40mm |

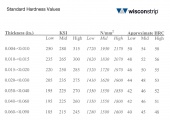

Standard Hardness Values

The range of standard hardness values for our hardened and tempered strip steel is a function of the material thickness and the intended application. The attached table is to be utilized as guideline.

Low range: recommendation for applications where a higher degree of bendability / formability is desired e.g. band saw types

Mid range: recommendation for flat springs and valve steel applications where also blankability is required

High range: recommendation for certain blanking applications and for material such as power springs

Low range: recommendation for applications where a higher degree of bendability / formability is desired e.g. band saw types

Mid range: recommendation for flat springs and valve steel applications where also blankability is required

High range: recommendation for certain blanking applications and for material such as power springs

Thickness Tolerances

voestalpine Precision Strip WI offers a standard thickness tolerance T3 according to the internationally accepted Swedish Tolerance Table. Continuity of a precision thickness tolerance has a direct effect not only on part functionality in many applications but also on the processing parameters of specialty operations used manufacturing those products. It can even directly impact the cost of those operations when considering issues such as die life in precision stamping or the grinding of strip edges.

| Thickness range (inch) | Tolerance T3 (+/- inch) |

| 0.0079" - 0.0098" | 0.00024" |

| 0.0099" - 0.0123" | 0.00028" |

| 0.0124" - 0.0157" | 0.00031" |

| 0.0158" - 0.0196" | 0.00035" |

| 0.0197" - 0.0247" | 0.00039" |

| 0.0248" - 0.0314" | 0.00047" |

| 0.0315" - 0.0393" | 0.00051" |

| 0.0394" - 0.0491" | 0.00067" |

| 0.0492" - 0.0629" | 0.00079" |

| 0.0630" - 0.0787" | 0.00090" |

| 0.0788" - 0.0940" | 0.00098" |