Additive Manufacturing

Additive manufacturing is one of the most advantageous production methods for parts with complex shapes and integrated functions, as it pushes the boundaries of conventional manufacturing. Even the most complex structures, such as curved internal channels, can be printed with our premium AM grades by adding metal powder layer by layer.

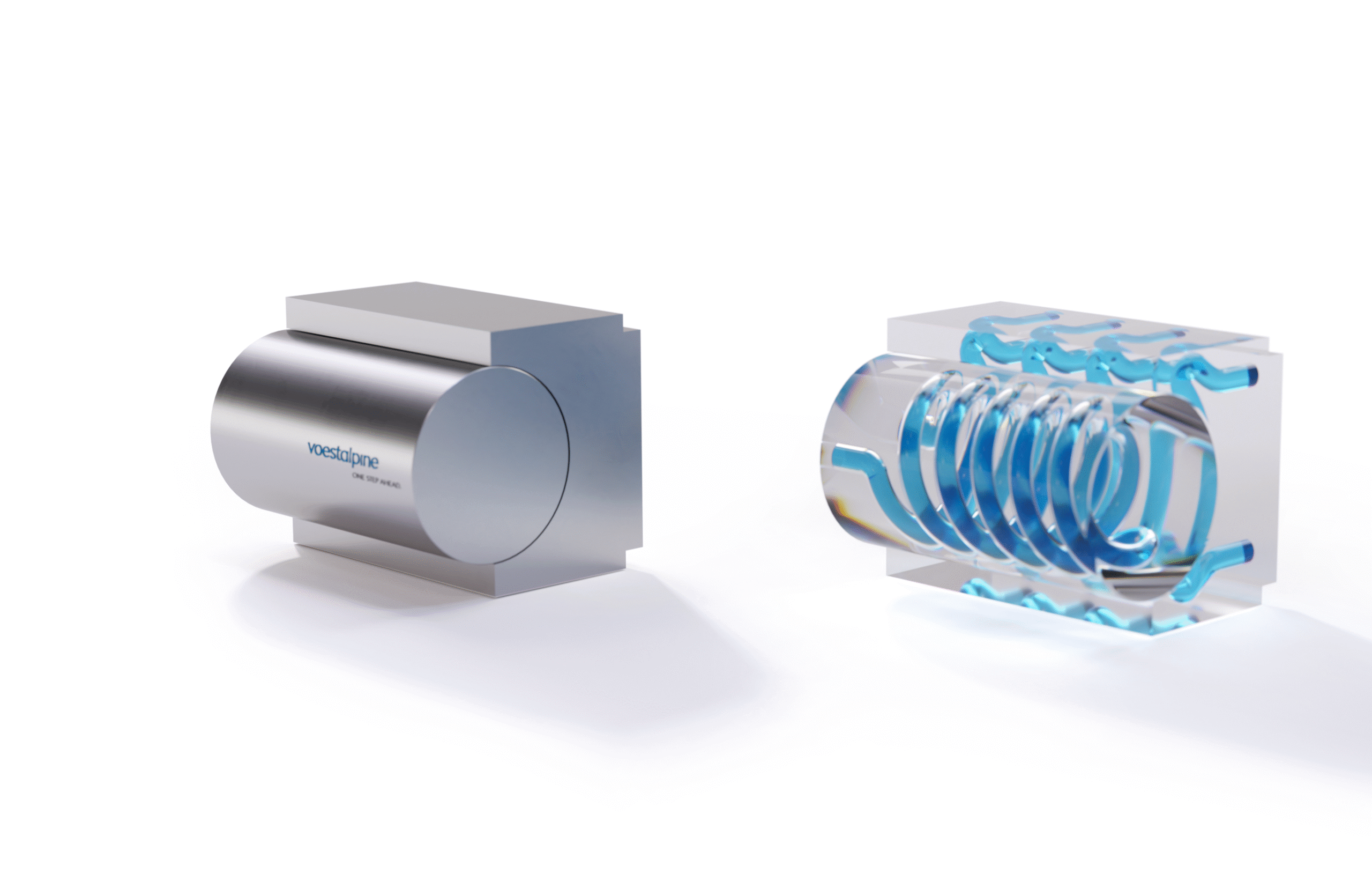

In high pressure die casting and plastic injection molding, shorter cycle times in part production can be realized using AM’s design capability of creating tailored conformal cooling designs (compared to conventionally manufactured tooling inserts). Conformal cooling also provides a more homogeneous temperature distribution in the mold during the injection process, which reduces distortion and thus can lead to lower scrap rates. AM’s design also facilitates the incorporation of channels for sensor integration without disrupting the temperature control of the mold to provide real-time data and production monitoring capability.

Many of our Engineered Products, for high pressure die casting and plastic injection molding, are available as additively manufactured components.

designed for pure performance

designed for pure performance

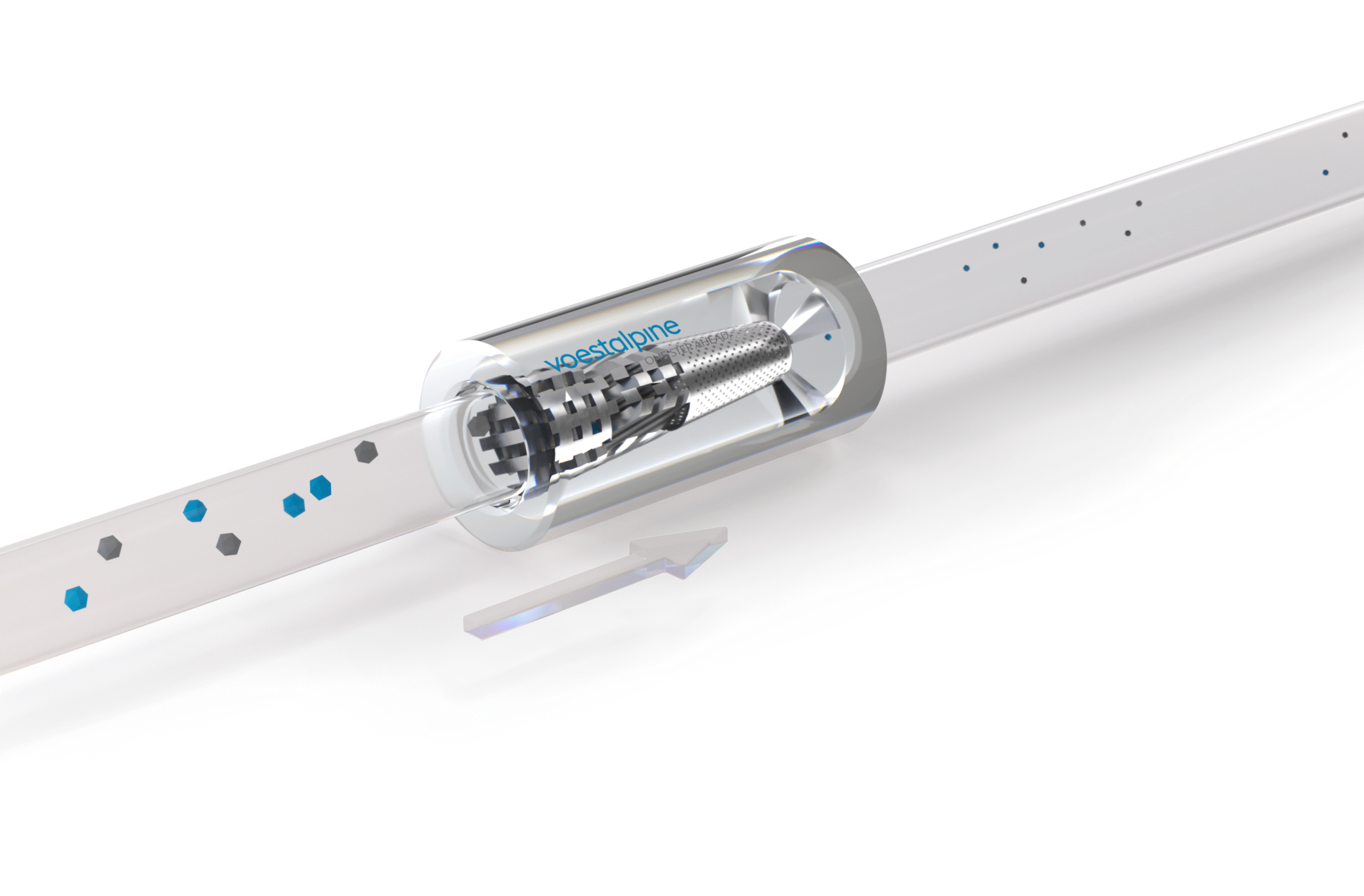

Flow Filter V & X

Nozzle filters are used to prevent contamination from the plastic melt causing blockages or interruptions to the injection process. These contaminates can cause damage to hot runner systems, resulting in extended downtime and increased maintenance costs.

View More designed for pure performance

designed for pure performance

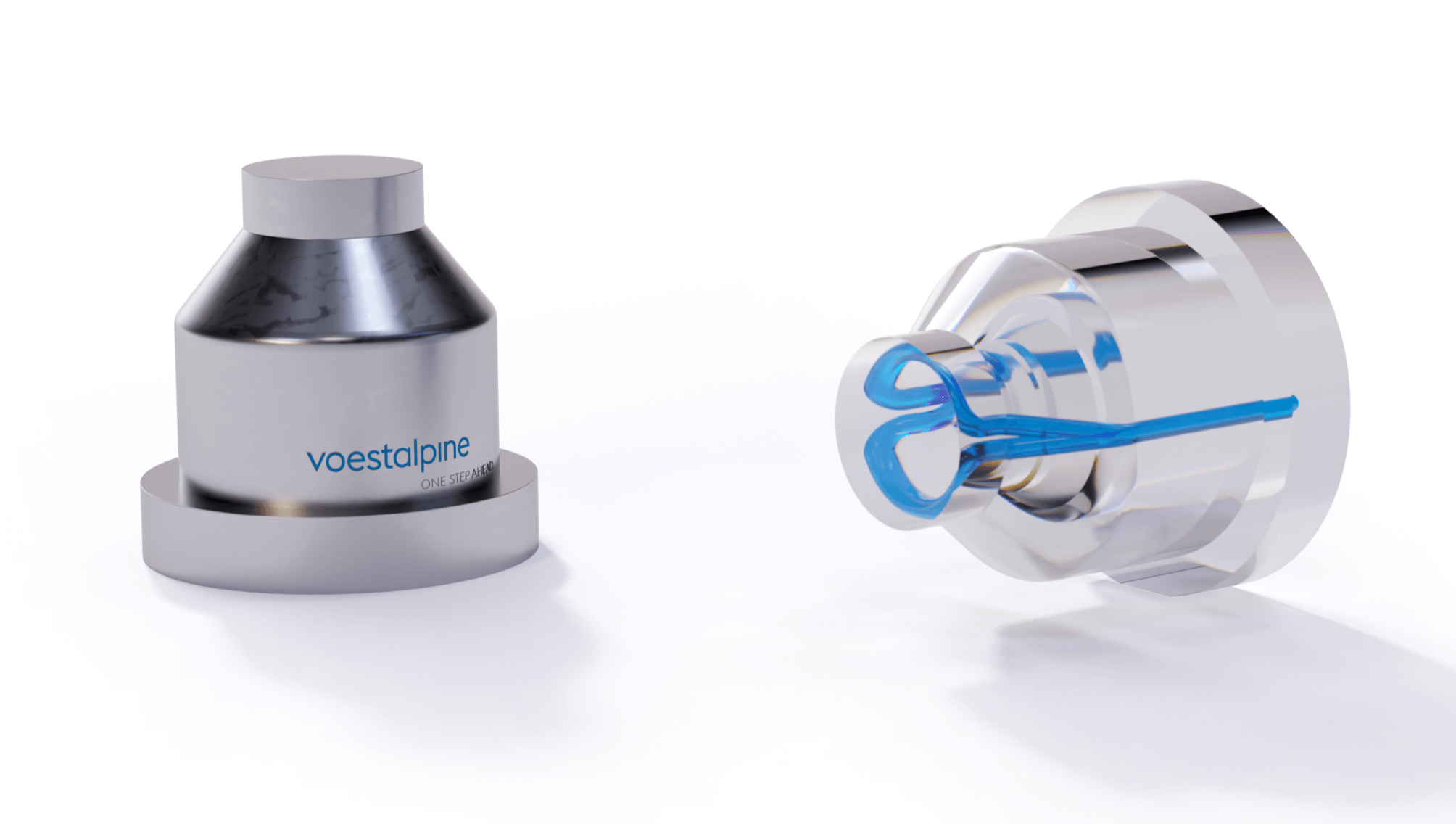

Insert for Botel Caps

voestalpine Inserts for Bottle Caps have optimized conformal cooling solutions, enabling our customers to run a stable and highly efficient production with a minimized cost per plastic part produced.

View More designed for pure performance

designed for pure performance

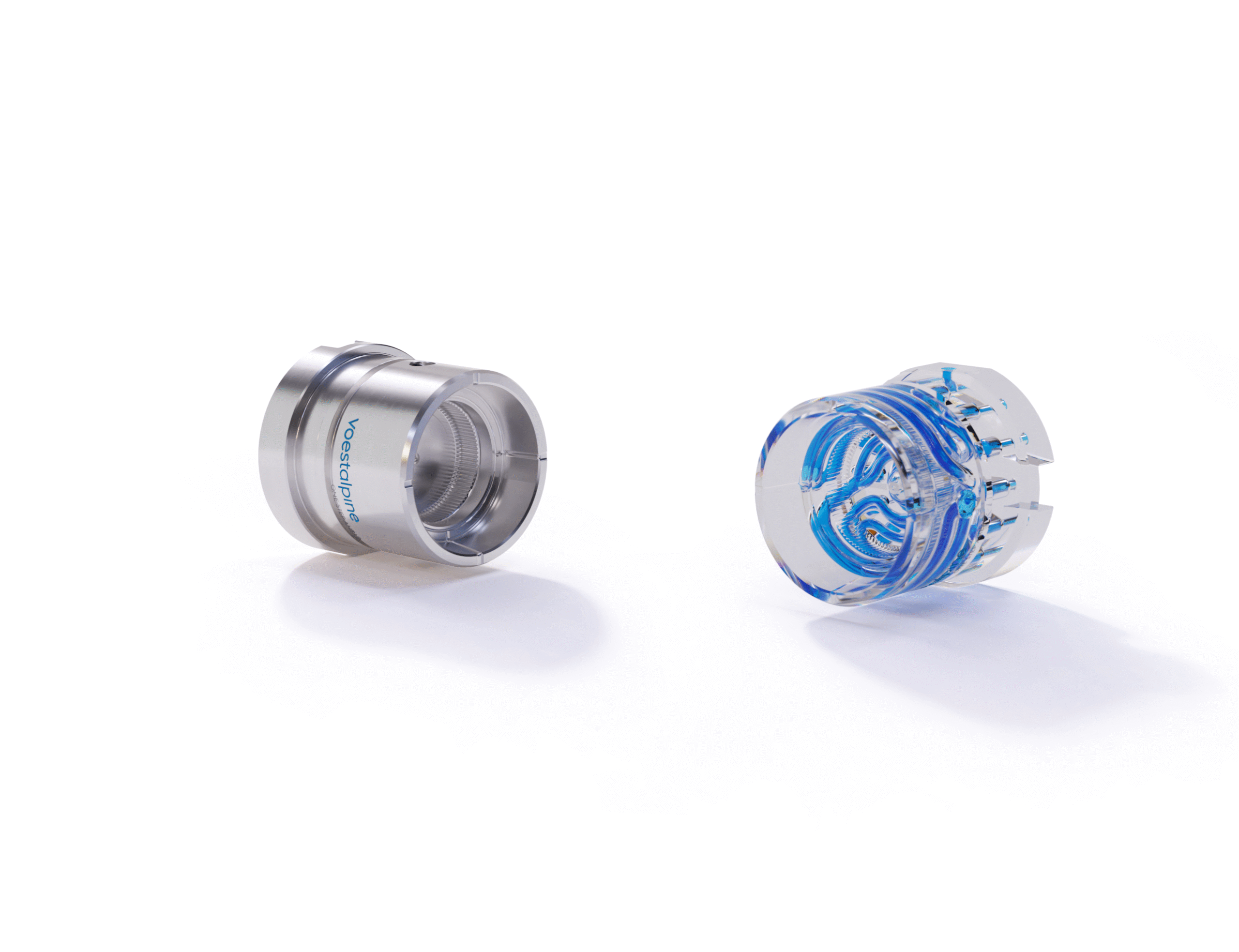

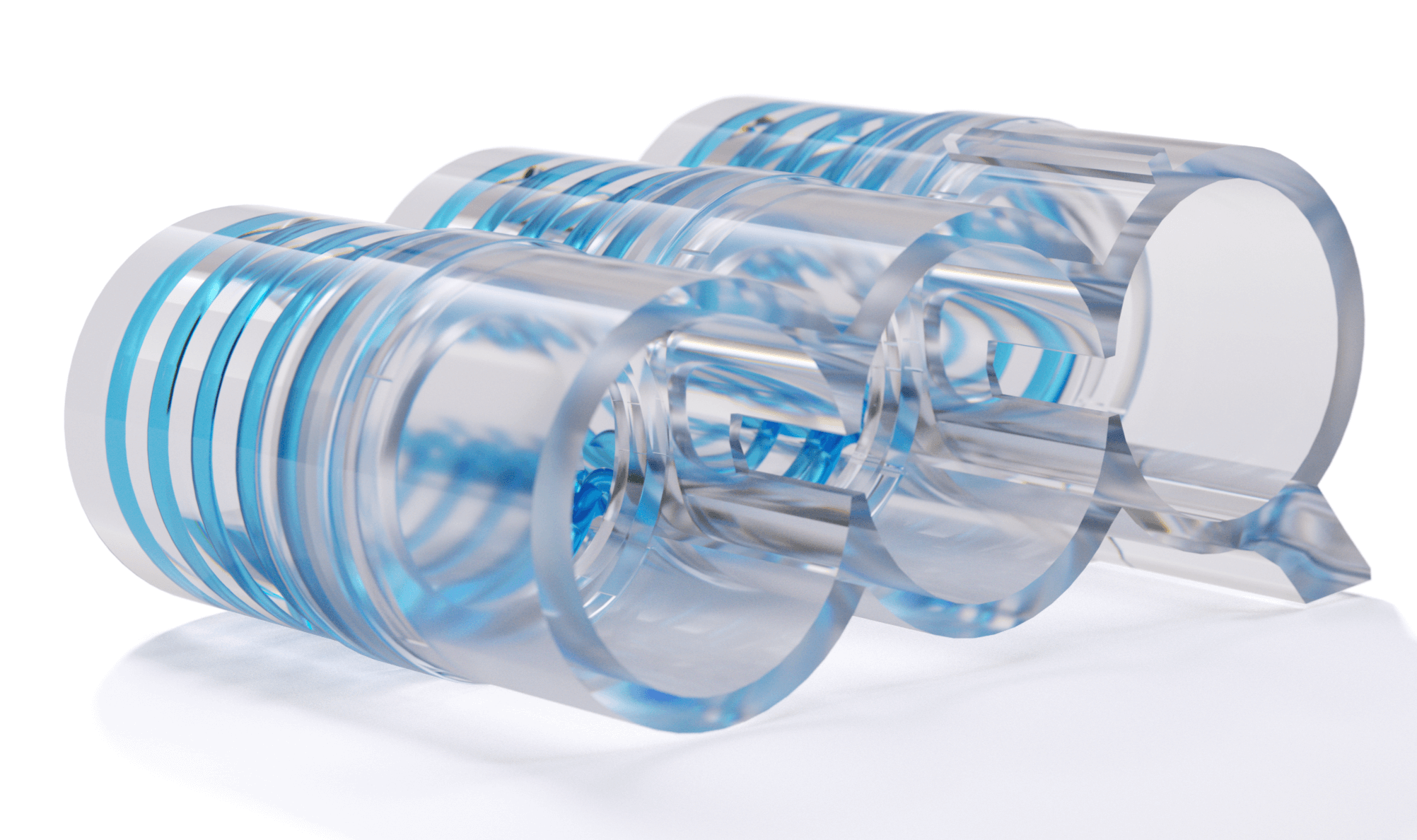

Inserts for Cylindrical Containers

voestalpine Inserts for Cylindrical Containers are produced using additive manufacturing and have optimized conformal cooling channels that enable our customers to run a stable and highly efficient production.

View More designed for pure performance

designed for pure performance

Inserts for Food Container Lids

Our Inserts for Food Container lids have optimized conformal cooling solutions, enabling our customers to run a stable and highly efficient production with a minimized cost per plastic part produced.

View More designed for pure performance

designed for pure performance

Inserts for PET-Preform

Our AM Inserts for PET-Preform have optimized conformal cooling solutions, enabling our customers to run a stable and highly efficient production with a minimized cost per plastic part produced.

View More designed for pure performance

designed for pure performance

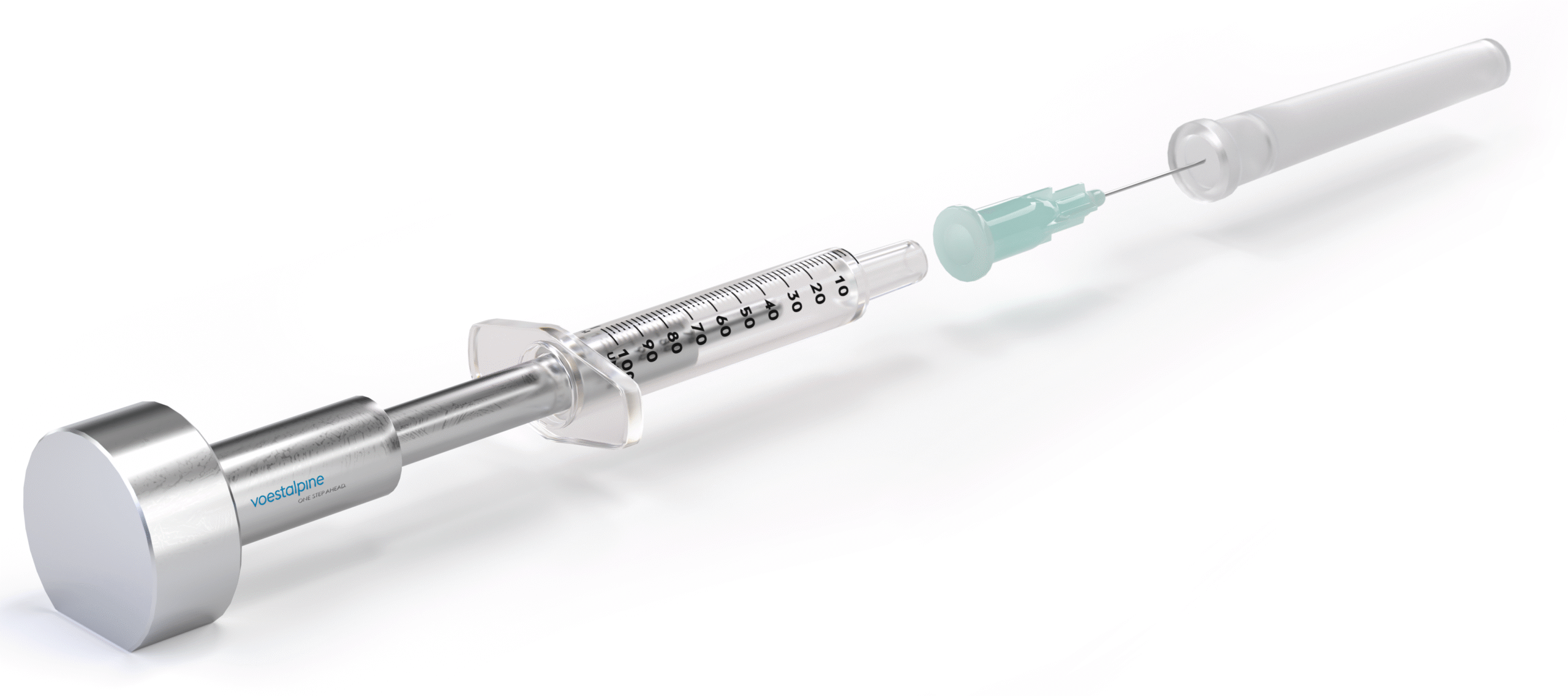

Inserts for Syringes

Our AM Inserts for Syringes have optimized conformal cooling solutions, enabling our customers to run a stable and highly efficient production with a minimized cost per plastic part produced.

View More designed for pure performance

designed for pure performance

Sprues – AM

voestalpine AM Sprues for die-casting applications are produced with premium materials by BÖHLER/Uddeholm. Used mainly in three-plate die casting molds, these finished products include voestalpine heat treatment, final machining, eifeler PVD coating, and customized conformal cooling.

View More designed for pure performance

designed for pure performance

Water Jackets – AM

voestalpine AM Water Jackets are exchangeable tool inserts used for casting aluminum engine blocks. The curved walls of this important component are very thin and generally vary in thickness from top to bottom. To fully leverage this complex form, a superior solution is required.

View More designed for pure performance

designed for pure performance

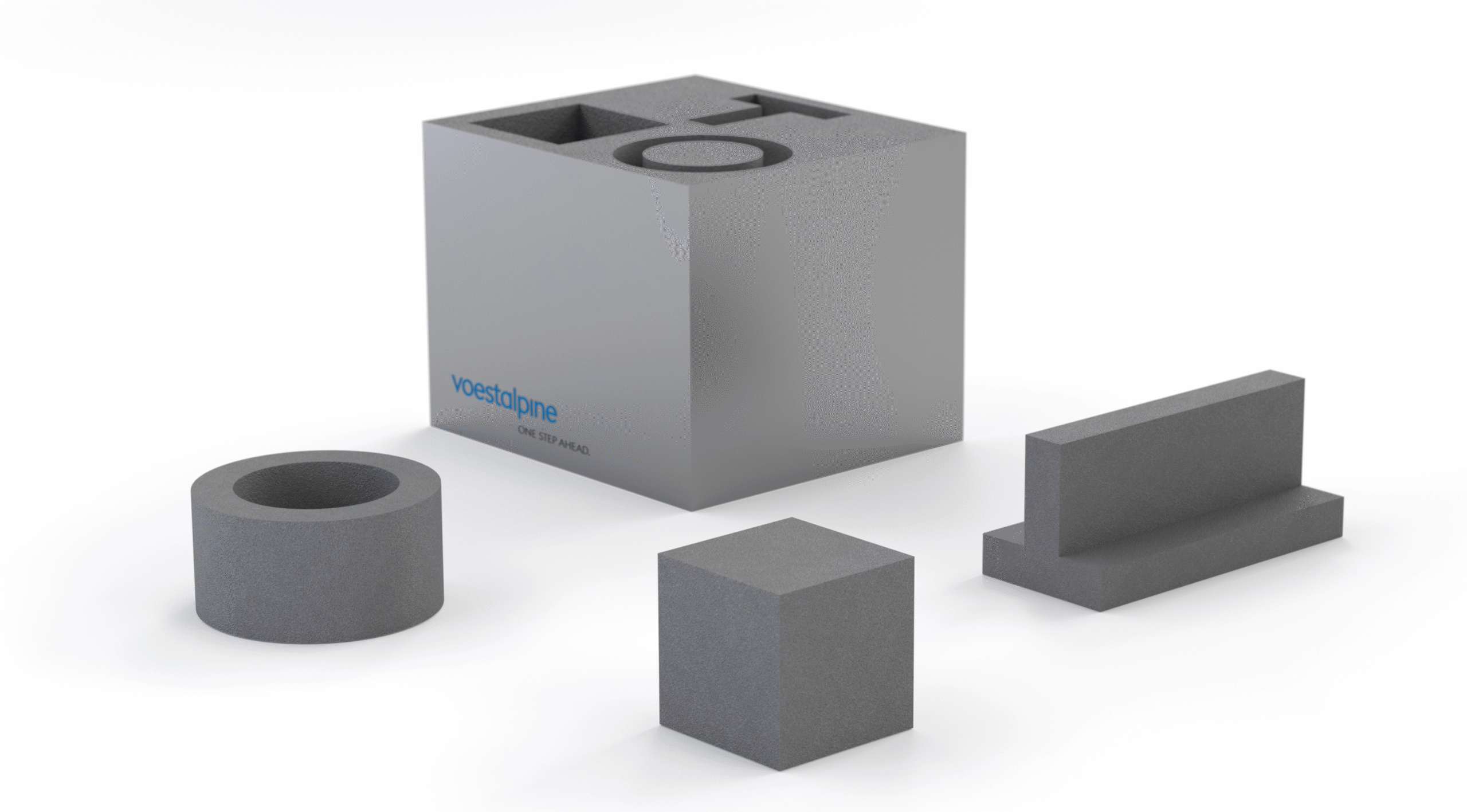

Venting Structures

Using additive manufacturing, venting structures with a microscopic porosity can be produced that allow a targeted release of compressed air and ensure that the mold remains air free during injection. These structures help to avoid defects caused by the diesel effect, which is a well-known industrial problem.

View More designed for pure performance

designed for pure performance

AM Distributors

voestalpine AM Distributors for die-casting applications are produced with premium materials by BÖHLER/Uddeholm. Used mainly in two-plate die casting molds, these finished products include voestalpine heat treatment, final machining, eifeler PVD coating, and customized conformal cooling.

View More