Our path to a green future

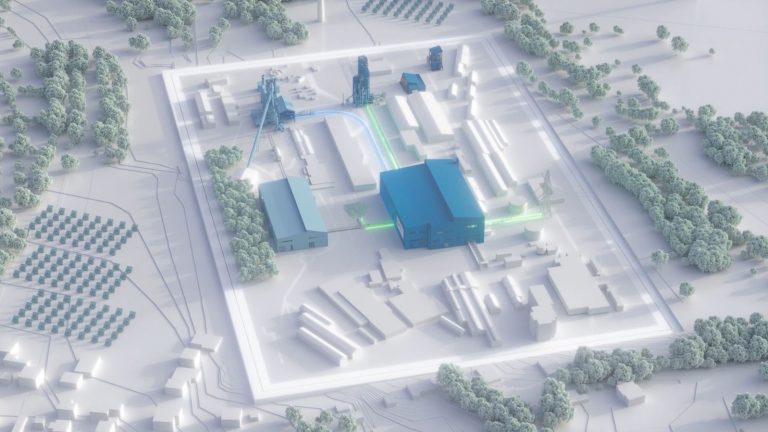

We are upping the pace of emissions reduction. greentec steel from voestalpine is Austria’s largest climate protection program. Starting in 2027, this program will reduce Austria’s annual CO2 emissions by almost 5%. 2024 marks the start of the partial shift from the blast furnace to the electric arc furnace (EAF) route—once unresolved funding issues in Austria are clarified.

- 3