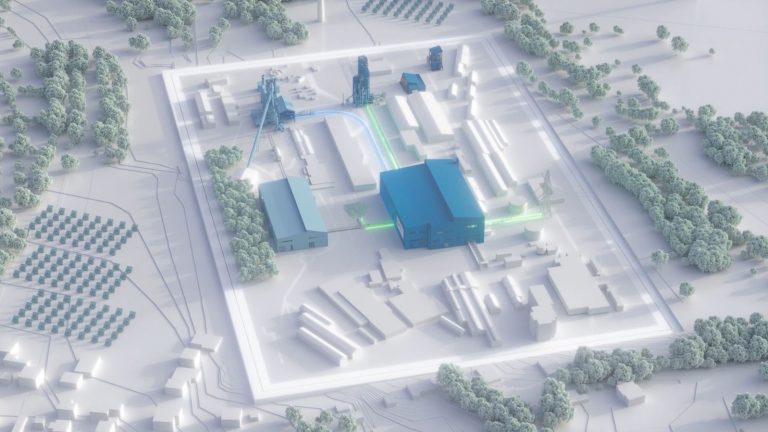

The state-of-the-art cold-rolled strip testing center at the site in Linz has now been successfully operating for several months. It is now gradually increasing the level of automation and digitalization in its ongoing operations through to 2025.

13 Jan, 2023