Steel goes digital

Steel with digital functions? Steel which monitors equipment conditions or sends weather reports? Innovative digital applications combined with advanced steel solutions—these are new areas of business for voestalpine. The Group’s “Digital Products” project closed with a meeting which brought together all sub-projects.

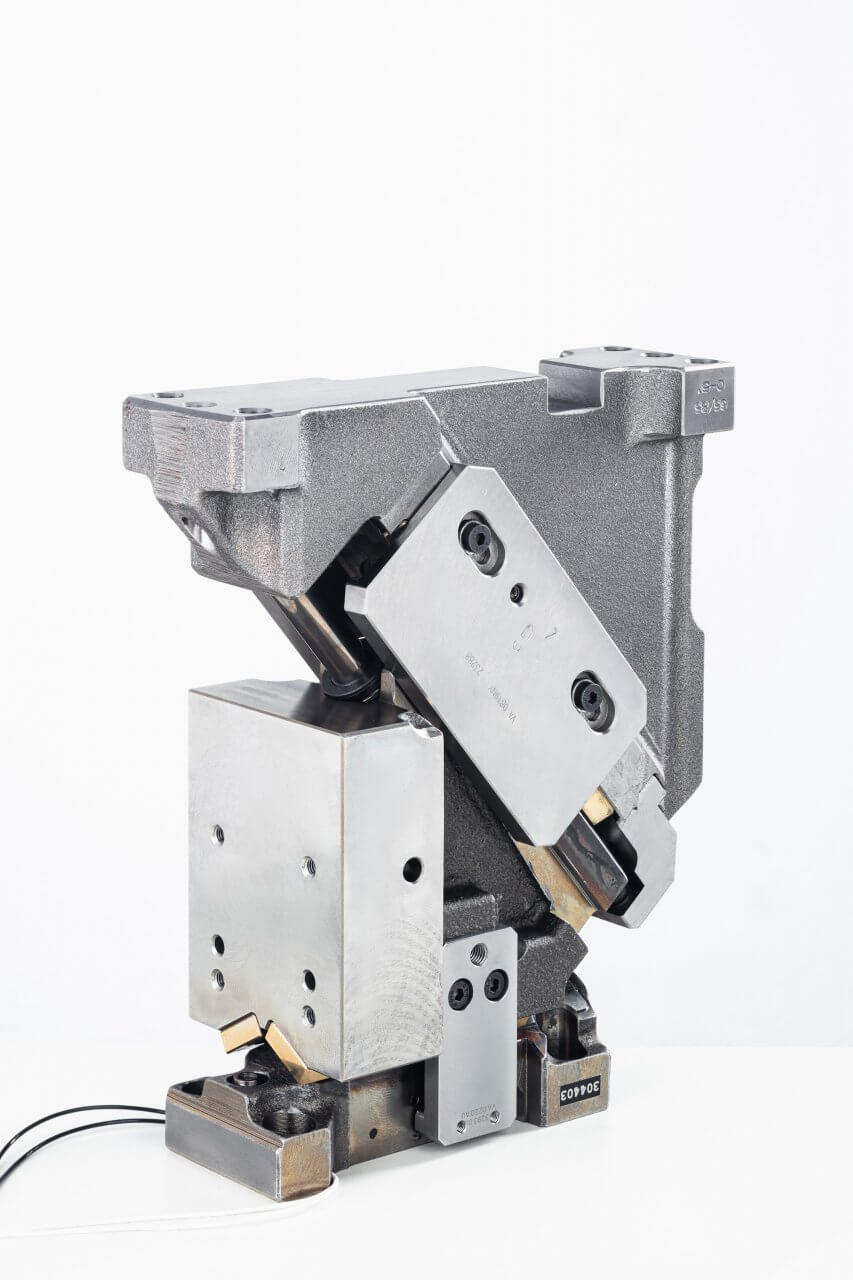

- 3