We supply steel in greentec steel Edition

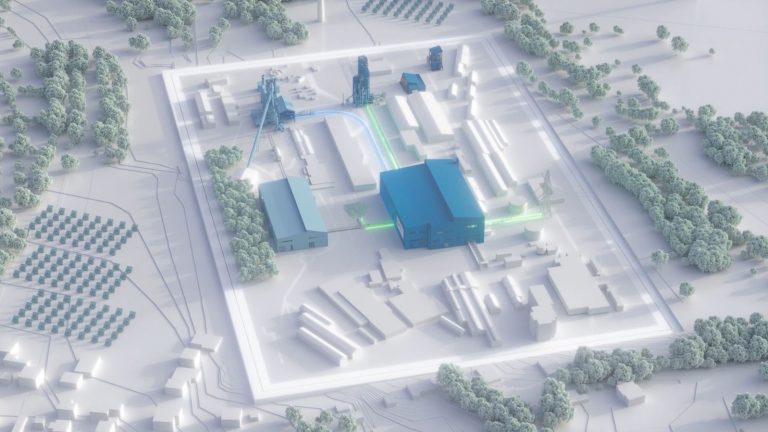

Since the end of 2021, we have been keeping a promise to the future: we are supplying a greentec steel Edition of all the flat steel products manufactured at our Linz site. The steel produced with a reduced carbon footprint is already proving its value in a diverse portfolio of applications.

- 20 Apr, 2023

- 4