greentec steel: the people behind the megaproject

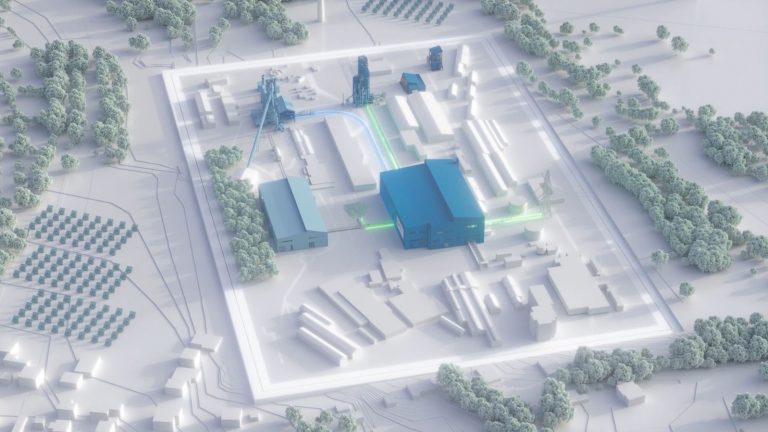

Austria’s largest climate protection program and the most extensive investment project in our company’s history: greentec steel. A project only made possible thanks to the people behind it. Read on to learn more about the members of the project team in Linz.

- 3