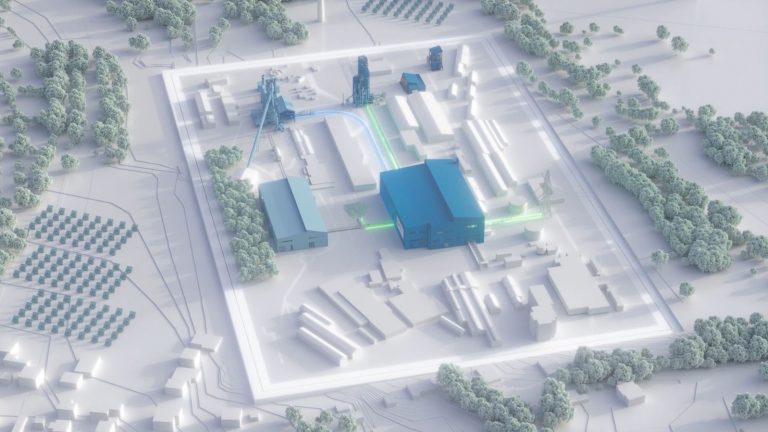

Green electricity for future steel production in Donawitz

From 2027, a new electric arc furnace in Donawitz will significantly reduce the greenhouse gas emissions from steel production. Green electricity is essential for the successful start of production.

- 20 Sep, 2023

- 3