Quality culture ambassador

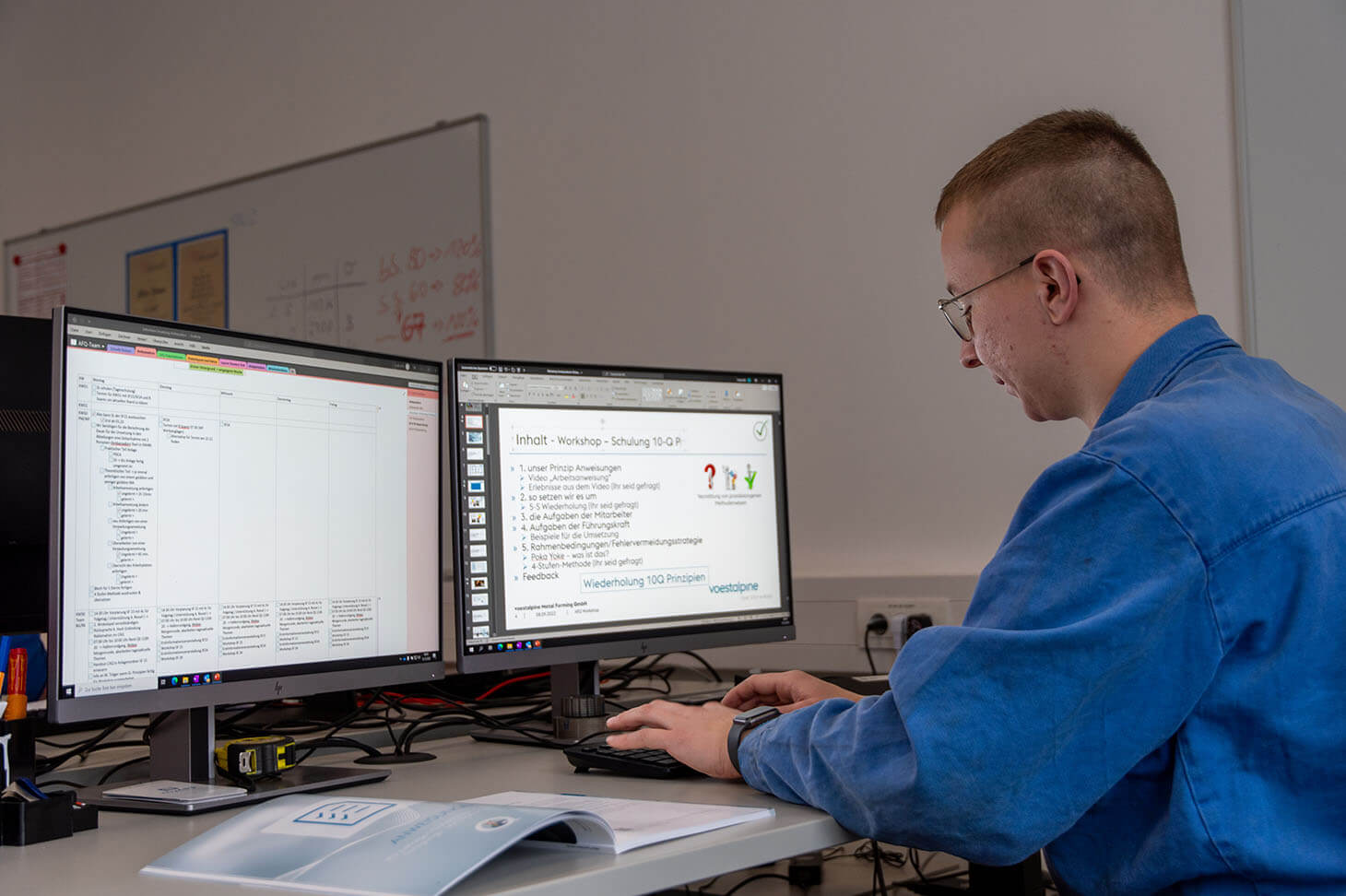

Willi’s position as Act for Quality Ambassador at voestalpine Automotive Components in Schmölln allows him to take a creative approach to his work. He provides insights into how he uses shoelaces, for instance, to get people to focus on quality.

- 15 Mar, 2023

- 4