Additive manufacturing: the aerospace test of maturity

- 3

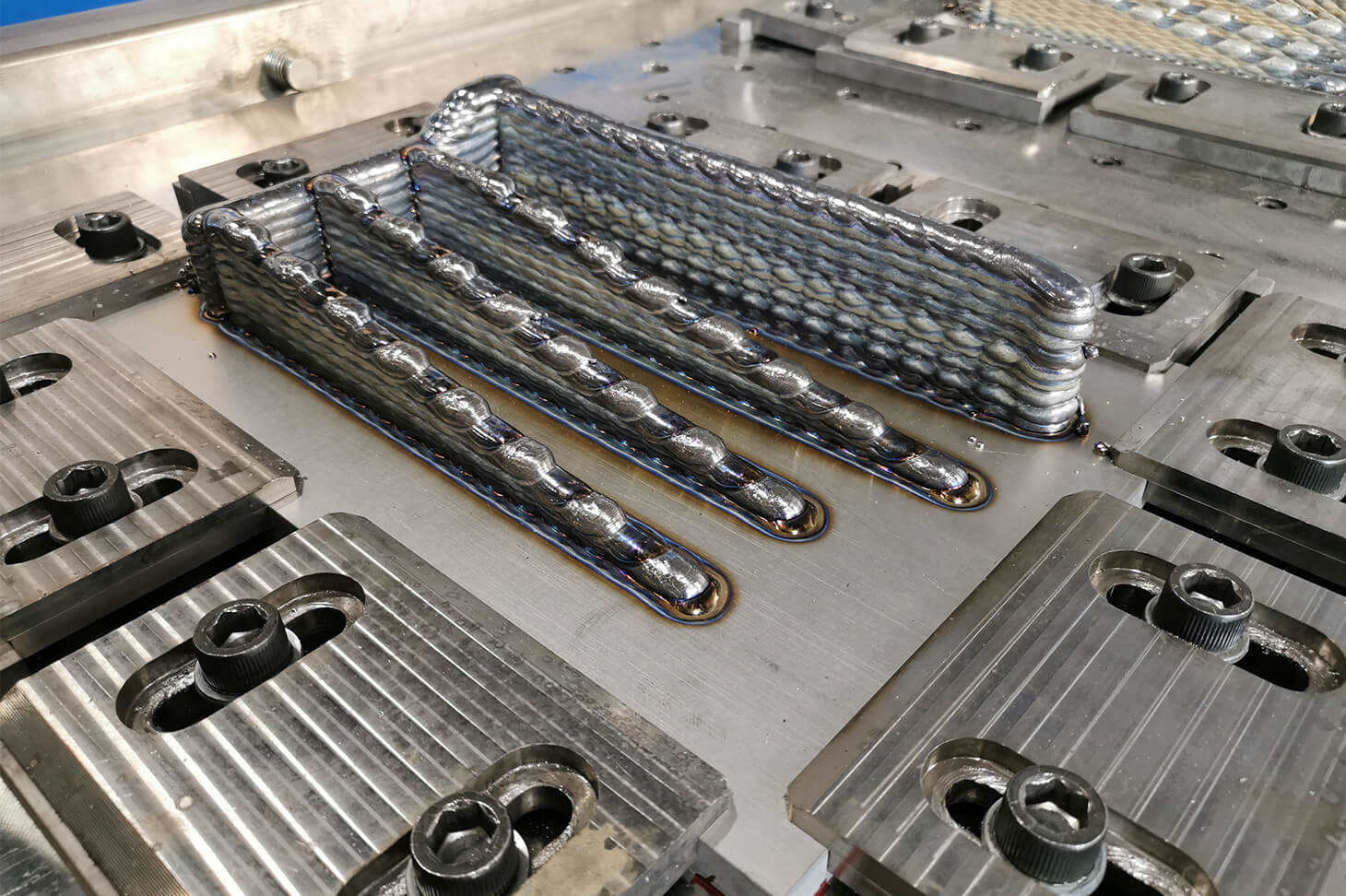

Additive manufacturing is an emerging and promising production technology, whose potential was recognized by the demanding aerospace industry some time ago. It includes processes in which material is applied in layers to create a single workpiece. However, additive manufacturing is very different from the established reductive production technologies such as machining forged parts when it comes to maturity. Consequently, much development work remains to be done before the technique is accepted as having reached the degree of technological maturity demanded by the aerospace sector.

voestalpine started some time ago to test metal-based additive manufacturing technologies for its customers in the aerospace segment. However, the significant demands placed on aircraft components make research and suitability testing complex and time-consuming. Whereas in other sectors, such as toolmaking, testing in practice is not inherently dangerous, safety-critical aircraft components may only be installed once it has been shown that they reliably meet all quality standards to the full—and assuming they have received all the necessary approvals. For that reason, in the aerospace sector new production methods generally require a much higher level of technological maturity than in other industries. This is also the case for additive manufacturing.

At voestalpine, the innovative technology is currently undergoing its aerospace maturity testing. Of particular interest here is wire arc technology using titanium, a promising material, as well as the production of powder especially designed for additive manufacturing. There is already a clear understanding of the technology, its possibilities, and limitations, and the relevant standards and specifications are currently in development. “We have the expertise needed to produce highly complex forged parts. That means that, in principle, we also have the expertise needed to produce aerospace components using additive manufacturing,” explains Paul B,, Chief Operating Officer of the Aerospace Platform in the voestalpine High Performance Metals Division. The technology will be first tested on less safety-critical parts.

If the technology achieves the necessary degree of maturity, some parts and components currently produced using conventional methods could, in future, be made using additive manufacturing. The added value this offers would be reduced production complexity, an optimized buy-to-fly ratio, and lower component weights. voestalpine’s investment in additive manufacturing is a clear investment in its future, so that it can also provide the level of support required by the demanding aerospace industry with this promising technology.

voestalpine has been an established supplier to the aerospace industry for around 100 years. The Group manufactures extremely complex, highly stressed, safety-critical components for renowned customers worldwide so that virtually every aircraft flies with a piece of voestalpine. After the severe turbulence during the COVID-19 pandemic, the company with its focus on aerospace is providing insights into the very special (aero)dynamics of this business area.

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.