(00:00 - 01:25)

Welcome to Wire Insights, the podcast of the latest developments, innovations and trends at voestalpine Wire Technology. From cutting-edge materials to sustainable production processes. Experience exciting insights into current projects that are revolutionizing the industry and find out how innovations made of wire are changing the world.

Whether you are a technology enthusiast, an industry professional or just curious about the future, this podcast is for you. Tune in and join us. Welcome back to Wire Insights, your go-to podcast for deep dives into the world of voestalpine Wire Technology, innovation and engineering excellence.

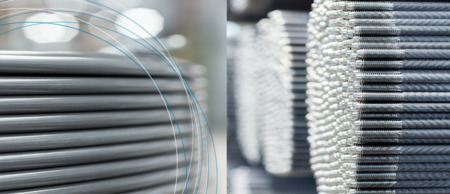

In today's episode Wire Excellence, a deep dive into our core products of cold heading steel grades and prestressing wire. We are exploring two highly specialized and impactful topics. These materials are essential in applications where strength, precision and reliability are non-negotiable, from automotive components to large-scale infrastructure projects.

To help us understanding more about these fascinating materials, we are joined by two experts from voestalpine Wire Technology.

(01:20 - 01:55)

First, a warm welcome to our guests, Mr. Uwe Tertinek. It's great to have you with us. Could you please introduce yourself and tell us about your background and your role?

Hello and thanks for inviting me. I'm really happy to be here. So, as an Application Engineer, I'm responsible for supporting our customers with any technical questions they might have.

I studied material science at the Montanuniversität in Leoben and joined the company back in 2012. I spent six years working in research and development before switching to Application Engineering in 2018.

(01:56 - 01:25)

And also joining us today is Mr. Dieter Kalcher. Welcome to Wire Insights. We'd like to hear about your journey and what you do at voestalpine Wire Technology.

Also a warm welcome from my side. I started as an apprentice at our site in Bruck an der Mur over 35 years ago. After many interesting tasks, some of which were also outside of Bruck, I had the opportunity three years ago to take on the team leadership for sales and application engineering, also for our construction products and thus also for prestressing steel wire.

(02:33 - 03:48)

Mr. Tertinek, what areas of application are there for cold heading steels?

Cold heading steels are one of the most important product groups for our business unit. They are used everywhere in our daily life where precise, durable and often complex shaped components are required. Such as different kind of screws, fasteners and anchors. So typical application areas include industries like automotive, mechanical engineering, household appliances, so-called white goods, the energy sector and last but not least the construction industry.

In general, cold heading steels are used wherever good surface quality and high formability are required. Additionally, their strength increases through cold forming which is particularly relevant for the final component and its intended use. Beside the classic and well known steel grades, we also have so-called AFP grades in our standard product portfolio.

AFP stands for Advanced Ferritic-Perlitic. Those micro-alloyed steels do not require heat treatment to achieve desired properties. So they are ideal for high strength parts that are typically quenched and tempered after forming.

(03:49 - 05:14)

What properties make cold heading steels particularly suitable for the manufacture of precision components? There are quite a few very important requirements and properties of cold heading steels. First, they have a high cold formability. They are able to undergo extensive plastic deformation without cracks or fractures.

This requires high purity and a uniform microstructure. Especially important for multi-stage forging processes that are widely used in the industry is a good toughness. The material must remain ductile and not become brittle and needs uniform mechanical properties.

Very important as well is a good surface quality. A uniform smooth surface is necessary as even minor surface defects can lead to cracks during forming and thus to material failure. Steels are often supplied with phosphate soap and or polymer coatings to reduce friction during forming steps, which also positively affects tool life.

Due to customer production processes, cold heading steels must meet very tight tolerances and high shape accuracy. So in short, cold heading steels must offer a perfect balance between good formability and specifically adjusted high strength, while also ensuring excellent surface quality and dimensional accuracy.

(05:15 - 07:45)

How does the production process for cold heading steels differ from other types of steel and what advantages are there in terms of production within voestalpine Wire Technology? Special requirements in the production of cold forming steels include for example a very precise chemical composition with narrow limits.

Tight tolerances for elements like carbon, manganese, sulfur and phosphorus are important for good formability. Also important is a very low level of non-metallic inclusions, as inclusions can cause cracks during cold forming. The wire rolling process itself involves precise temperature control and targeted cooling to produce a fine-grained homogeneous microstructure.

Here I also want to refer to the podcast with Mr. Kienreich, where he explains the benefits of thermomechanical rolling in detail. At our site here in St. Peter-Freienstein we perform so-called GKZ annealing, meaning annealing for spheroidized cementite. This reduces wire strength and improves formability.

When it comes to the advantages of cold heading steels we deliver as voestalpine Wire Technology, I want to point out especially our high purity steel quality. Our raw material supplier voestalpine Stahl Donowitz produces steel with the state-of-the-art secondary metallurgy. This ensures high purity and thus excellent formability.

The wire rolling mill in St. Peter-Freienstein can deliver very tight tolerances across a wide range of wire diameters, the basis for a trouble-free process in forming machines. There is an ongoing R&D project aiming to launch a phosphate-free alternative to traditional phosphating. This saves the customer a cleaning step and improves the CO2 footprint of the product.

We as voestalpine Wire Technology offer a fully integrated process chain from the steel mill to the drawn wire, everything from a single source. This minimizes potential errors and ensures consistent quality. Our unique R&D infrastructure with the Techmet and the Wire Technikum provides the basis for continuous development and product quality improvements.

And of course we focus heavily on CO2 reduced production, for example the green steel initiative at voestalpine. At the end of the day, this makes cold-heading steel greener.

(07:46 - 09:44)

Before we move on a big thank you to Uwe Tertinek for the valuable insights and perspectives you've shared with us today. Now let's turn our attention to a topic that's fundamental to structural engineering.

Pre-stressing steel wire. Dieter Kalcher is here with us and he brings a wealth of experience in this area. Mr. Kalcher could you walk us through what makes prestressing wire so essential? What role does pre-stressing steel wire play in the modern construction industry and what advantages does it offer?

Pre-stressing steel puts the concrete in the structure under pressure, thus limiting the tensile stresses that occur and therefore the cracks in the concrete. Concrete is generally very resistant to compression but is more sensitive to tensile stresses. The pre-stressing steel is also responsible for absorbing dynamic stresses, for example in concrete slippers.

Okay, how is the quality and strength of pre-stressing steel wire ensured? The quality of pre-stressing steel wire begins with the use of qualified high carbon wire rod as the starting material. The tensile strength of the pre-stressing steel wire produced is determined by the diameter of the wire rod and the individual cold deformation steps in the drawing and stabilizing process. In addition to the high tensile strength with correspondingly good ductility, the stabilization process also achieves very low relaxation of the pre-stressing steel wire.

This means that the prestressing steel wire can permanently maintain the pre-stressing force applied in the concrete of structure. And the stabilization process also ensures that the wire is very straight when in use.

(09:45 - 10:41)

What challenges and trends do you see in the future for the use of pre-stressing steel wire and what solutions does voestalpine Wire Technology offer?

Prestressing steel wires are always divided into tensile classes according to existing standards and approvals.

One noticeable trend is certainly the development towards higher tensile strength in the same diameter range. Furthermore, we are also noticing the trend from classic concrete construction. So this is prestressing steel wire anchored in concrete towards the use of pre-stressing steel wire in wind energy.

Prestressing of concrete wind towers with external pre-stressing. In this case, the pre-stressing steel wire is located outside the concrete as an external tendon to tension the individual concrete segments of the tower together.

(10:42 - 11:03)

Thank you for the comprehensive insights. It's always enriching to dive so deeply into your areas and your expertise. And that brings us to the end of this episode of Wire Insights with Uwe Tertenek and Dieter Kalcher. Thank you to our guests for joining us today.

It's been a pleasure hearing your thoughts and experiences.

(11:04 - 11:37)

Before we wrap up, we'd like to hear what's currently keeping you busy. Any exciting projects or ideas you're working on that you'd like to share with our listeners? Mr. Kalcher first.

Of course, I think we have a very interesting project. We are currently working on a large stay cable bridge project in Taiwan. Designed by Zaha Hadid Architects and we are supplying the strand products for this project.

I would also like to take this opportunity to thank the entire team that makes it possible for us to realize such large projects.

(11:38 - 12:12)

And what projects are you currently working on, Mr. Tertenek?

As an Application Engineer, I'm in contact with many customers from various industries. But what is important for all of them and for our future in general is resource saving and CO2 reduced production throughout the entire process.

Therefore, the upcoming conversion of our steel base to EAF is of course a topic that accompanies me every day. Thank you. That wraps up this episode of Wire Insights with Uwe Tertinek and Dieter Kalcher.

(12:13 - 12:37)

A big thank you to our today's guests for sharing your expertise and perspectives. Your insights truly sparked some powerful conversations. And to our listeners, thanks for tuning in.

We've got something exciting lined up for next time. So stay curious and stay connected. Until then, take care and keep exploring the world of voestalpine Wire Technology.