Research & Development

Your partner for innovation

Research & Development (R&D) at voestalpine Wire Technology means practical support for your product development.

With state-of-the-art laboratories, our own technical centers, and a strong network of universities and partners, we accompany you from the initial idea to series production and ensure that materials and processes are precisely tailored to your requirements.

This results in customized, innovative wire solutions that not only impress technically, but also accelerate your entire development process and open up new application possibilities for demanding areas of use.

The MetLab is the heart of our development of new alloys and special steels. It enables fast, flexible development and testing of new materials – even for individual customer requirements.

Equipment & possibilities:

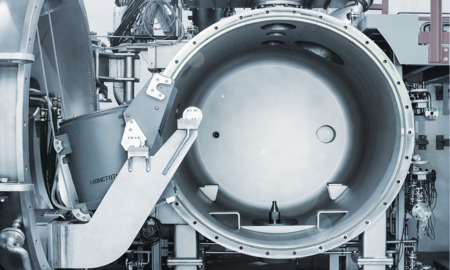

TechMet offers large-scale testing facilities under realistic conditions. From laboratory scale to industrial casting format – optimal transition from development to series production.

Equipment & capabilities:

Wire products are comprehensively tested, simulated, and further developed at the Technical Competence Center Wire. Practical simulation and testing of all relevant properties - from formability to surface quality.

Equipment & capabilities:

We cooperate closely with leading research institutions and universities, including:

4 steps to a customized wire solution with application and R&D expertise

Do you have any questions about R&D services or would you like more information about our application and R&D expertise?