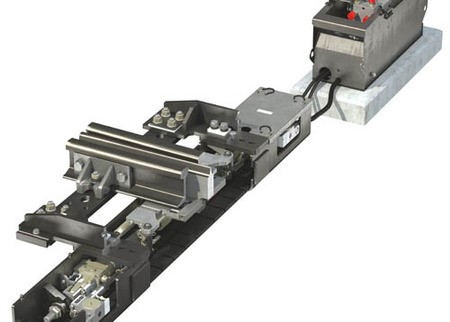

HYDROSTAR® Setting System

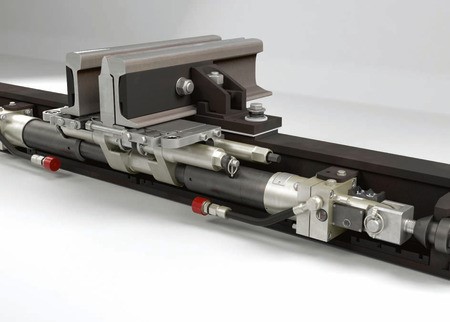

HYDROSTAR® is a modern combined point operating, locking and detection system. It is used for switches (HYDROSTAR® ZV) as well as for movable point frogs (HYDROSTAR® HB).

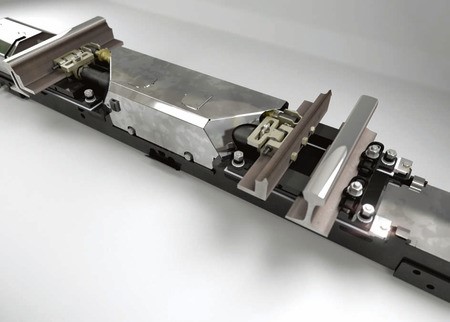

Thanks to positive locking of the closed switchblade as well as the open one, the system is predestined for the use on high-performance tracks.

Its innovative encapsulated design is the main reason for a massively reduced preventive maintenance effort in the area of turnouts. All variants of HYDROSTAR® require only one power unit which enables a very convenient integration into the interlocking system. Smaller turnouts with movable point frogs can even be operated with a combined version that runs both turnout components using again only one power unit.

Benefits

- Compatibility with various interlocking systems

- Easy installation and handling

- Slim-fit design => perfect for installations in tunnels

- Minimal maintenance requirements

- Sealed components

- Low life cycle costs

- Suitability for all turnout types

- Availability for switch assemblies as well as swing nose crossings

- Highest reliability and availability combined with maximum safety

- A system approved according to CENELEC 50126/50129

Maximum Performance. The HYDROSTAR® setting system provides you with optimum efficiency by consistently minimizing life-cycle costs. Its innovative encapsulated design is the main reason for a massively reduced preventive maintenance effort in the area of turnouts. All variants of HYDROSTAR® require only one power unit which enables a very convenient integration into the interlocking system. Smaller turnouts with movable point frogs can even be operated with a combined version that runs both turnout components using again only one power unit HYDROSTAR® is suitable for all turnout geometries and track superstructures. The use of individually tested assemblies and just-in-time delivery to the installation point guarantee maximum availability of your railway track. Fully automated tamping when installing in hollow sleepers also guarantees the highest level of efficiency.

Technical characteristics of HYDROSTAR® setting systems

|

Designation |

Value / Type |

|

Number of possible locking and setting units |

2 to 6 (HYDROSTAR® ZV) |

|

1 to 3 (HYDROSTAR® HB) |

|

|

Maximum setting force |

3500 to 9000 N (HYDROSTAR® ZV) |

|

10000 N (HYDROSTAR® HB ) |

|

|

Operating pressure |

max. 100 bar |

|

Active force onto the switch blade |

up to 2500 N |

|

Active force onto the movable point frog |

up to 2000 N |

|

Ambient temperature |

-40 °C to +70°C |

|

Trailable |

non-trailable |

|

Supply voltage of the drive motor |

3-phase-current 400 VAC |

|

Interface to the interlocking system |

4 wire technology |

|

Interlocking monitoring voltage |

60 VDC |

|

Gauge |

≥ 1430 mm |