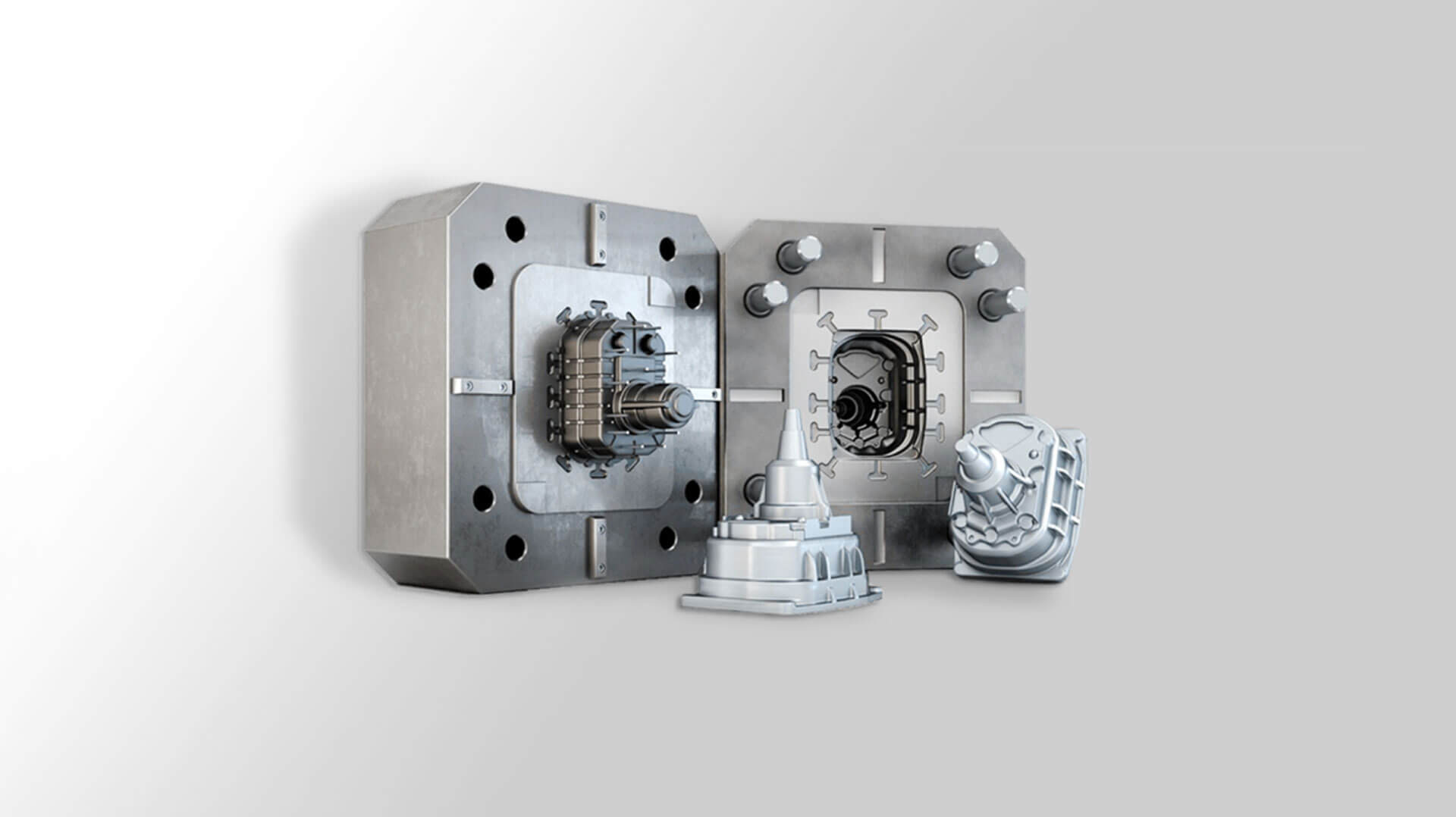

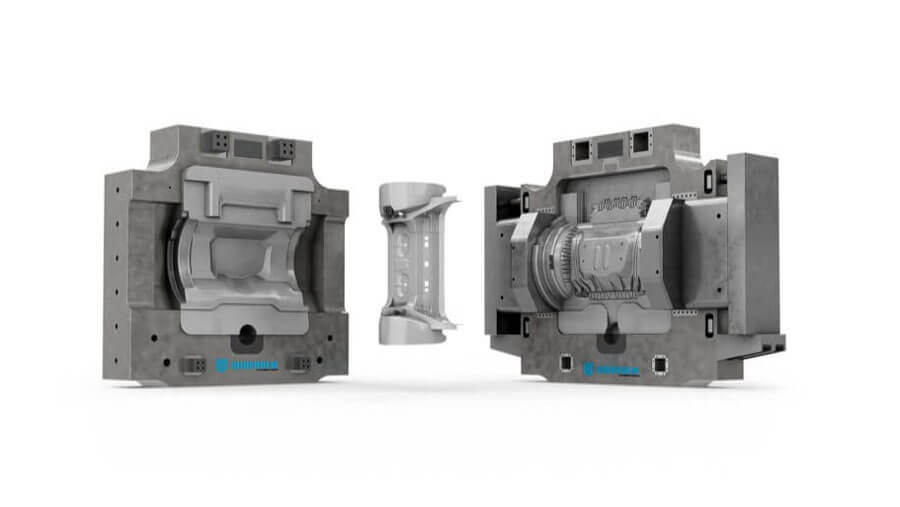

High Pressure Die Casting

Ready for Your Casting Challenges

We Understand Your Process And Your Pressure.

You need more than just good steel—you need a partner who knows your world, helps you cut costs, speed up production, and boost your margins. That’s why we offer a holistic die approach: one team, one network, all the solutions you need.

Key strengths of our approach:

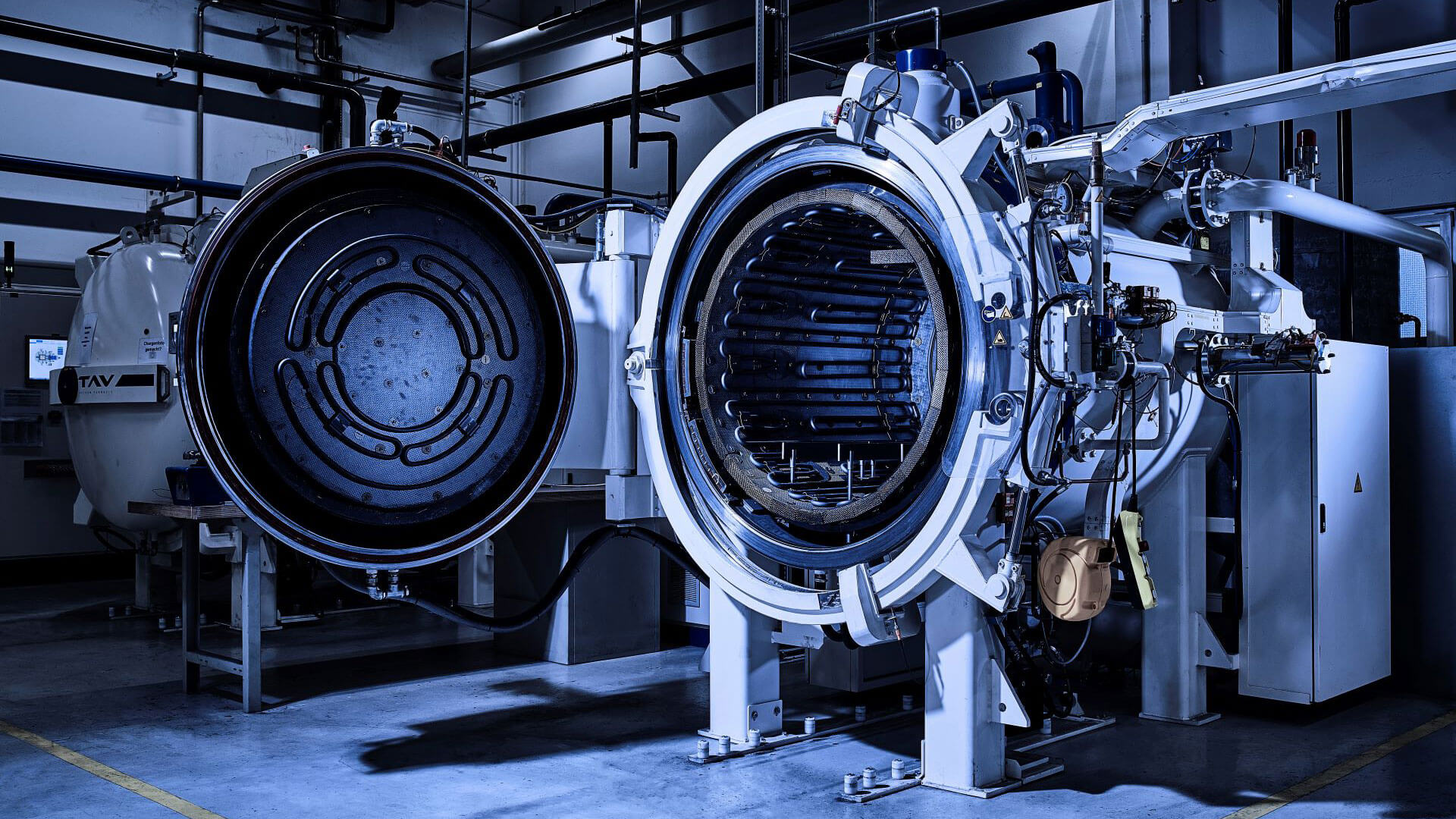

- Single Point of contact: Tool Steels, Additive Manufacturing Powder, Heat Treatment, PVD Coating —all from a single source

- Technical support and consulting

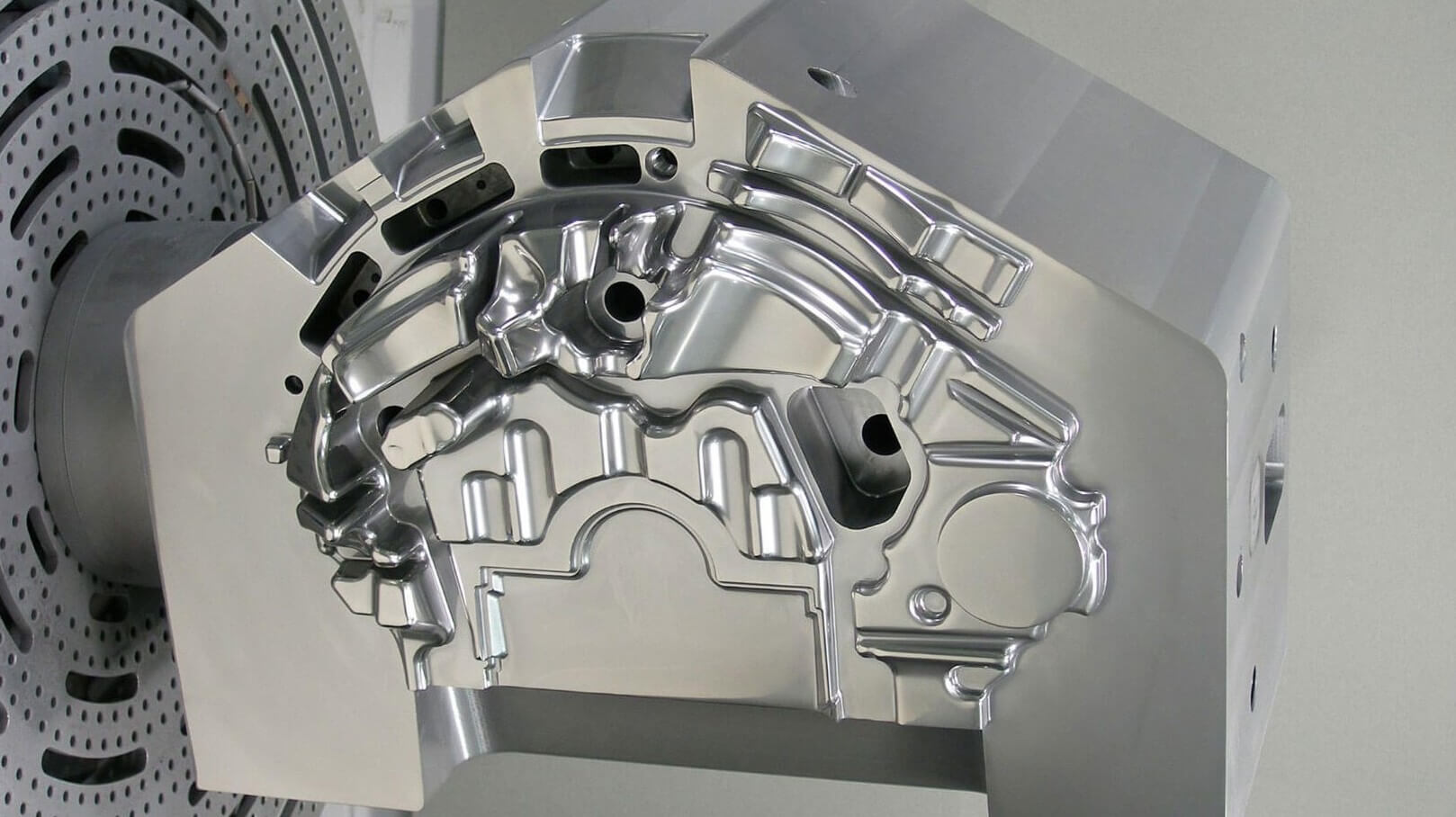

- Optimized Components

- Laser Metal Deposition for Tool Repair

- Global network, local support: we’re close to you, wherever you are

From material selection to technical support, we offer tailored solutions for every need.

Download HPDC Brochure

OEE Improvement

We know what OEE improvement really means on the shop floor—less downtime, more output, and better margins. Here are a few real cases that speak louder than theory. Want to see more? Let’s set up a meeting and we’ll show you what’s possible for your business.

Real-World Case Studies

Extended Maintenance Intervals

Maintenance intervals extended by 87.5%

Ready to reduce the risk in your casting operation?

inSPire is our sustainability framework, built for real impact. It’s driven by a dedicated team focused on practical projects that make a difference—helping our customers and our industry move toward a more sustainable future, one step at a time.

Closing Material Cycles

Closed Loop: Circular Economy in Action

We take your worn-out dies and tools off your hands and recycle them through our closed-loop process. You free up space, avoid disposal hassles, and know your old tools are being put to good use—turned into new steel, safely and responsibly, with your know-how protected.

Maximizing Recycling, Securing Supply

We’re serious about using less primary raw material. Already, 81% of what goes into our melt shops is recycled. Our goal: over 90% by 2030. We’re always looking for new ways to recycle, reuse, and secure the key materials our industry needs—so you can count on supply.

From materials to lifecycle support—we’re here to help.

Our TOP Services

Our TOP Products

CONTACT US FOR MORE INFORMATION: