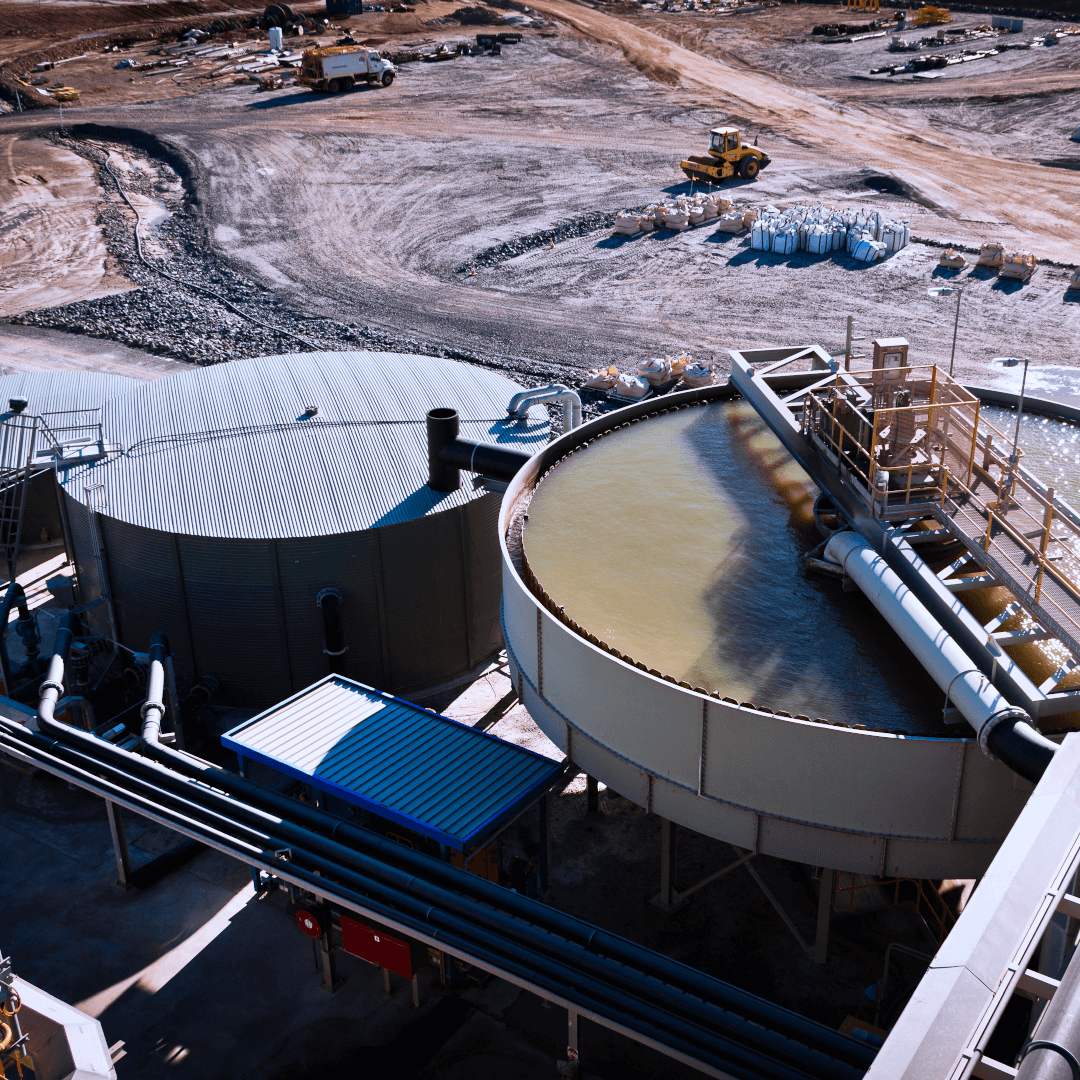

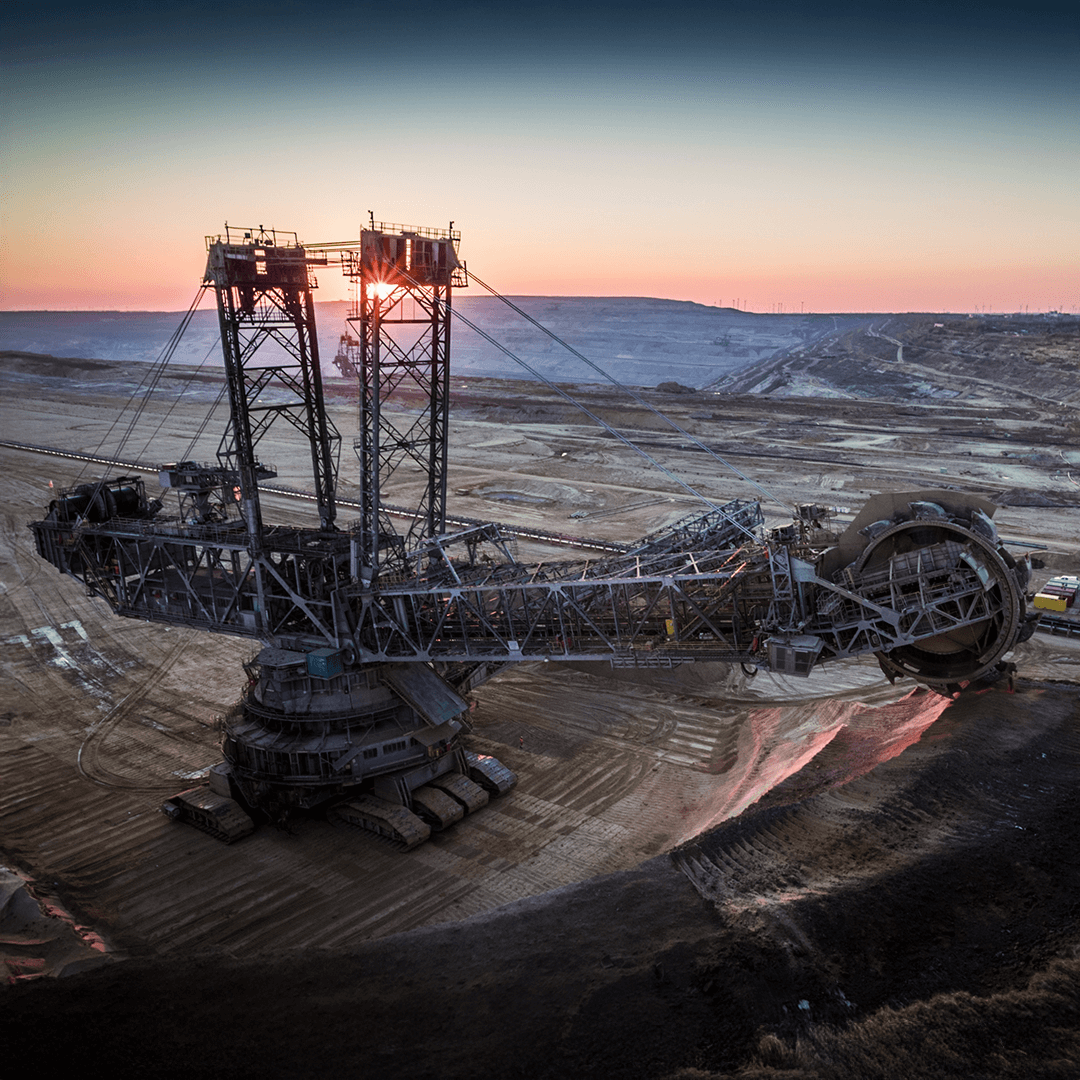

Mining

When Performance Matters.

High performance materials for the mining industry

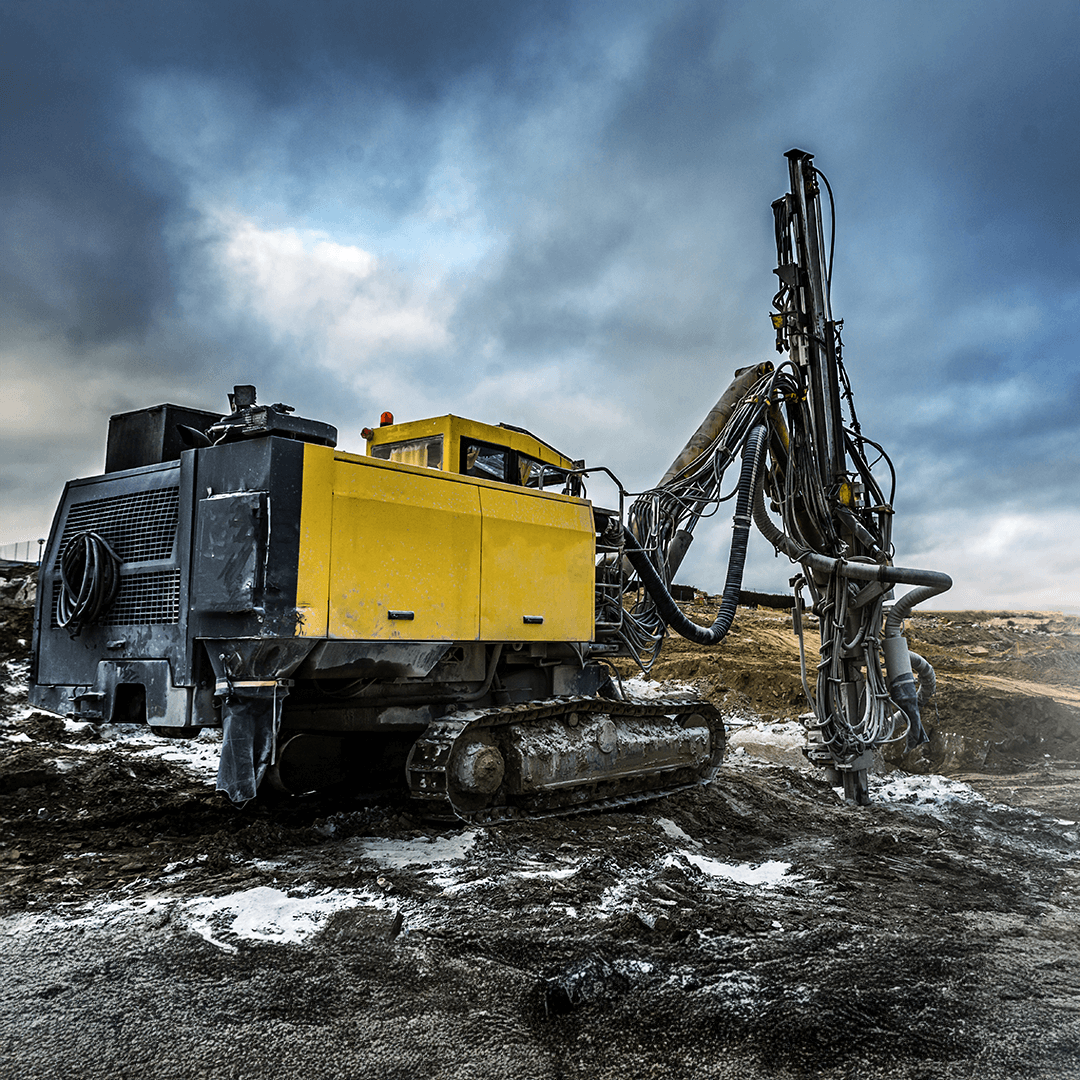

The mining industry is one of the most demanding industry sectors when it comes to component wear and abrasion. Traditionally, many of the parts produced for this sector rely on standard steel grades, but what if there was another way?

The adoption of voestalpine high performance tool steels in the mining sector has been proven to be successful across a wide range of applications from drill clamps to slurry pump valves. With the resulting performance increase – in many cases improving the service life of a component by a factor of 10 – over traditional high tensile or quench and tempered grades, means tool steels can prove to be an extremely cost effective solution in many mining applications.

Explore what is possible

voestalpine High Performance Metals offer a extensive selection of tools steels, with over 250 different grades available – each offering unique chemical compositions and material properties – you can be assured we have material grades designed to perform in the most demanding environments.

While tool steels are an excellent alternative to standard high tensile steel grades, tool steels also offer several benefits over tungsten carbide solutions, particularly in applications requiring toughness. While tungsten carbide is harder and more wear-resistant, tool steels provide improved machinability and ductility, making them less brittle and better suited for impact and dynamic loading conditions.

This makes tool steels an ideal alternative as they are easier to machine and process, which in turn reduces maintenance time and costs. Additionally, they are tool steels more affordable and available in a wider variety of grades tailored for specific applications.

Designed for the harshest environments

Our premium tool steels have many of the characteristics found desirable in the mining sector, these include:

- Wear Resistance

- Toughness

- Ductility

- Chipping Resistance

- High Hardness

Meet our Experts

Our experts are on hand to help you with your next project – contact us using the contact form below.

Global

Matko Bozanic

Americas

Miguel Carrion

Europe & Middle East

Mohit Modi

Asia Pacific

Bernie Tee