Optimizing Tool Life in High-Volume Molding: A Case Study with 30% Glass-Filled Nylon (PA66)

In high-volume injection moulding, tool performance and consistency are crucial for operational efficiency.

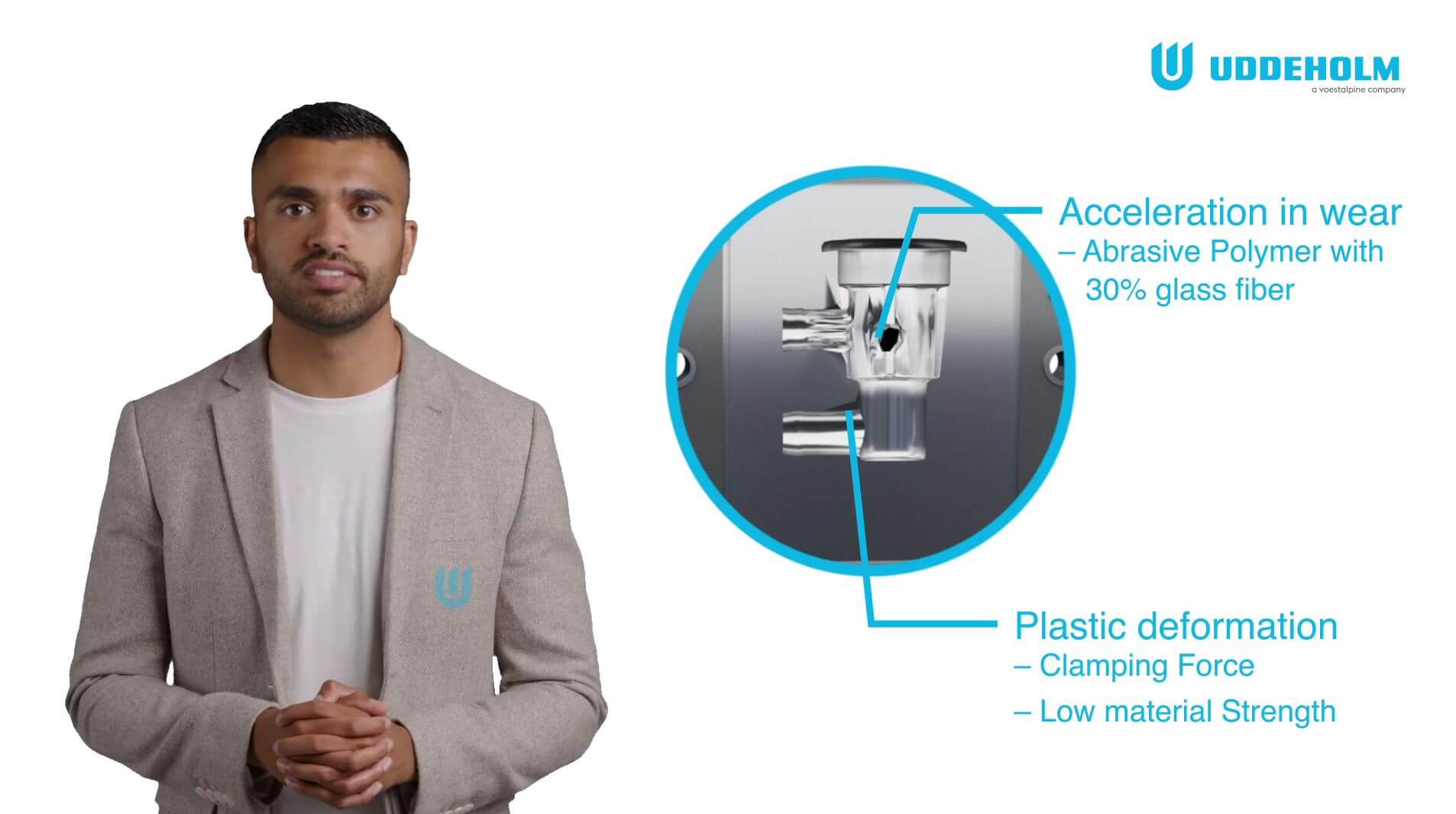

A leading manufacturer approached us with a recurring challenge while molding 30% glass-filled PA66—a highly abrasive engineering polymer. Their tool, made from Uddeholm Orvar Supreme at 44–46 HRC, had delivered consistent performance but was reaching its limit at around 1.5 lakh shots, mainly due to:

- Progressive plastic deformation

- Accelerated wear under continuous cycles

As this was a high-output application, the customer sought an option to further extend tool life and reduce downtime.

🔍 Our approach was application specific.

Uddeholm Orvar Supreme is a versatile and proven steel for demanding moulding applications. However, given the aggressive nature of this polymer and the need for extended tool life, we evaluated alternative solutions within our portfolio. We recommended an upgrade to Uddeholm Unimax—a grade designed for extreme wear conditions, with higher hardness and superior toughness.

✅ Why Uddeholm Unimax for this application?

- Better wear resistance

- Higher hardness (54–56 HRC)

- Improved resistance to plastic deformation

📈 The result?

The new Unimax tool has already surpassed 2 lakh shots and continues to perform reliably—demonstrating the value of selecting the right steel for the specific challenge.

This project reinforces an important principle:

Even among high-performance steels, the best choice depends on the application. Matching material properties with operating conditions is key to maximizing tool life and production efficiency.