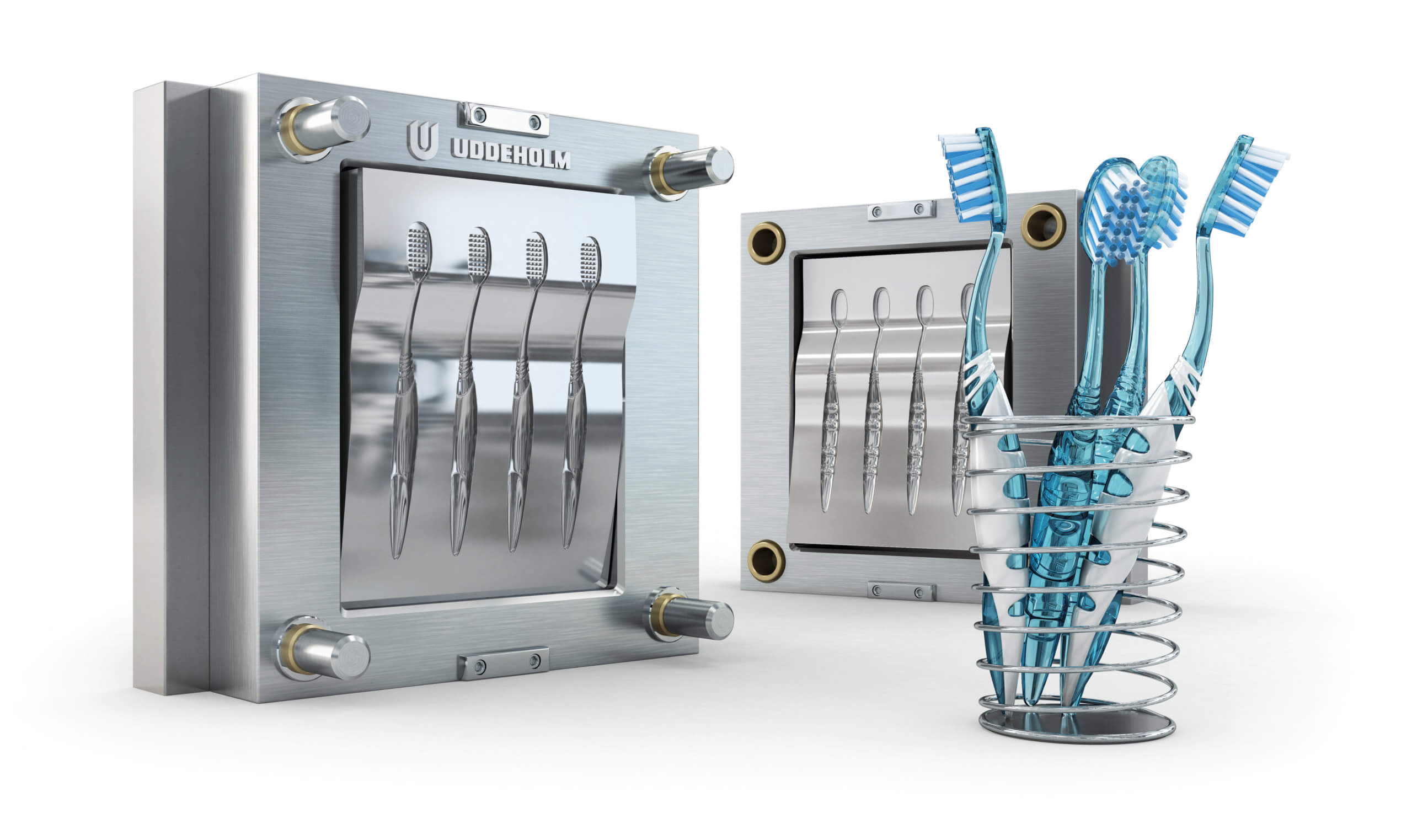

PLASTIC MOULD MATERIALS

Plastic Moulding is a part of our everyday lives. Car parts, mobile phones, spectacles, computer chassis are all manufactured by moulds. However, the materials needed to make these moulds often require unique and demanding characteristics. This is why it is crucial to select the correct steel grade for your specific mould. Below is a list of our BÖHLER and Uddeholm plastic mould steels that offer premium solutions to cater to the most demanding manufacturing requirements.

PLASTIC MOULD STEEL

ALUMINUM PLATE PRODUCTS

| PRODUCT | SPECIFICATION | DESCRIPTION | DOWNLOADS |

|---|---|---|---|

| 6061-T651 | Prehardened HB 73 | High machinability, high corrosion resistance | – |

| 7075-T651 | Prehardened HB 73 | Excellent corrosion resistance, high toughness | 7075-T651 – Technical Sheet |

| ACP 5080R & ACP 5080P | Prehardened HB 95 | Excellent wear resistance, high tougness | – |

| Duramold-2™ | Prehardened HB 150 | Good wear resistance | Duramold-2™ – Technical Sheet |

| QC-10 | Prehardened HB 160 | High corrosion resistance, high toughness | QC-10 – Technical Sheet |

COPPER ALLOY PRODUCTS

| PRODUCT | SPECIFICATION | DESCRIPTION | DOWNLOADS |

|---|---|---|---|

| MOLDMAX HH | Prehardened HRC 40 | This copper alloy has a hardness and strength comparable with standard tool steels but its thermal conductivity is four to six times higher. | MOLDMAX Brochure |

| MOLDMAX LH | Prehardened HRC 30 | Provides hardness and strength comparable with standard AISI P-20 tool steel and a thermal conductivity five-times higher. | MOLDMAX Brochure |

| MOLDMAX V | Prehardened HRC 28 | High conductivity, moderately high strength, copper nickel silicon chromium alloy with no beryllium. | MOLDMAX Brochure |

| MOLDMAX XL | Prehardened HRC 30 | The alloy provides excellent toughness, wear resistance and surface finishes. | MOLDMAX Brochure |

Contact voestalpine High Performance Metals Canada for further information

Fields marked with * are mandatory.