Driving the future of steel: #FavoriteMoments of our pioneering spirit

- 8

Around 750 researchers work at over 70 research locations worldwide, and the research budget for the 2025/26 fiscal year is EUR 241 million, making us one of Austria’s most research-intensive companies.

In a pilot project, we are working with WEB Windenergie AG WEB Windenergie AG to test how electricity from wind power can be sensibly integrated into energy-intensive steel production. With greentec steel, we have developed a long-term plan to make steel production more sustainable and decarbonize it step by step. This requires a lot of green electricity. That is why we are researching innovative processes and investing specifically in pilot projects that promote the use of renewable energies. At our Linz site, we are investigating how dynamic electricity generation from wind power can be optimally combined with the continuous processes of the steel industry. By analyzing and evaluating extensive data, we want to find out how the interaction between industrial production processes and renewable energy can be made more efficient.

Since 2023, RAG Austria AG has been conducting research into seasonal electricity storage in the form of hydrogen together with us and renowned partners from industry and science. Over several months, around 500,000 m³ of hydrogen was stored in an underground sandstone gas reservoir as part of the Underground Sun Storage 2030 (USS 2030) flagship project in Rubensdorf/Gampern (Upper Austria) and extracted from the reservoir in high purity. This allows the surplus amount of solar electricity generated in the summer months to be stored in sufficient quantities so it can be used in winter. The demonstration operation in Gampern has now been completed and the large-volume summer electricity storage in depleted gas reservoirs is ready for scaling.

In Styria, we are working on a research project in the field of circular economy. This involves recovering valuable metals from metal dust, which was previously considered a waste product. The aim of the project is to conserve resources and significantly reduce emissions. The research focuses on so-called steel mill dust – a residue from stainless steel production. Instead of disposing of this waste at great expense, we are working on an innovative process in the “HydroStäube” project that enables the recovery of high-quality alloy metals such as chromium, nickel, and zinc. With the help of hydrogen chloride, we were able to recover around 70% of the chromium and over 95% of the zinc and nickel – clear proof that circular economy in the metal sector works. In addition to us, the Montanuniversität Leoben, the competence center K1-MET, and Andritz are also involved in the project as further partners. The raw material recovery process could be put into practice in around two to five years.

Our British company, voestalpine Metsec plc, is currently investigating the role of computer models in the assessment of steel structures under fire conditions in order to offer digital alternatives to conventional physical fire tests. By using tools such as CFD (computational fluid dynamics) and FEM (finite element method; a computer-aided method for analyzing strength and deformation calculations), engineers can simulate fire dynamics and the reactions of structures in order to develop more efficient fire protection strategies without having to rely exclusively on costly physical testing.

A new plastic cable duct has been installed at the Hoorn marshalling yard (Netherlands). What makes it special is that it is made from recycled composite materials, such as rotor blades from wind turbines. The newly developed circular economy solution has proven to be robust, reliable, and significantly easier to handle than alternative products in practice because, for example, bends and corners can be easily and conveniently sawn into shape. With a composition of 98% recycled material, this innovation allows us to make a direct contribution to sustainable rail infrastructure, not only with steel, but also with plastics.

In the DusTES (Dust Thermal Energy Storage) project, an innovative fixed-bed heat storage system is being developed in collaboration with the Vienna University of Technology, Heger Edelstahl, and evon. The aim is to make dust-laden high-temperature waste gases from steel production even more efficient as a heat transfer fluid and to increase the utilization rate of waste heat from the current 45% to up to 97%.

As part of the A4M – Additive for Mobility research project, we are collaborating with the Vienna University of Technology, BMW, and MAGNA on additive manufacturing technologies for sustainable mobility. 3D printing primarily brings more flexibility to production than conventional processes – especially for small batch sizes. Instead of removing material from a blank, the component is built up layer by layer, e.g., by plasma welding or powder-based welding. As part of the project, we are working on 3D printing new casting molds using quartz sand – even large components weighing several tons. The casting mold is designed digitally and manufactured to fit precisely using a 3D printer. This technology can also be used to repair defective or worn machine components instead of having to replace them completely. This not only saves material, but also energy.

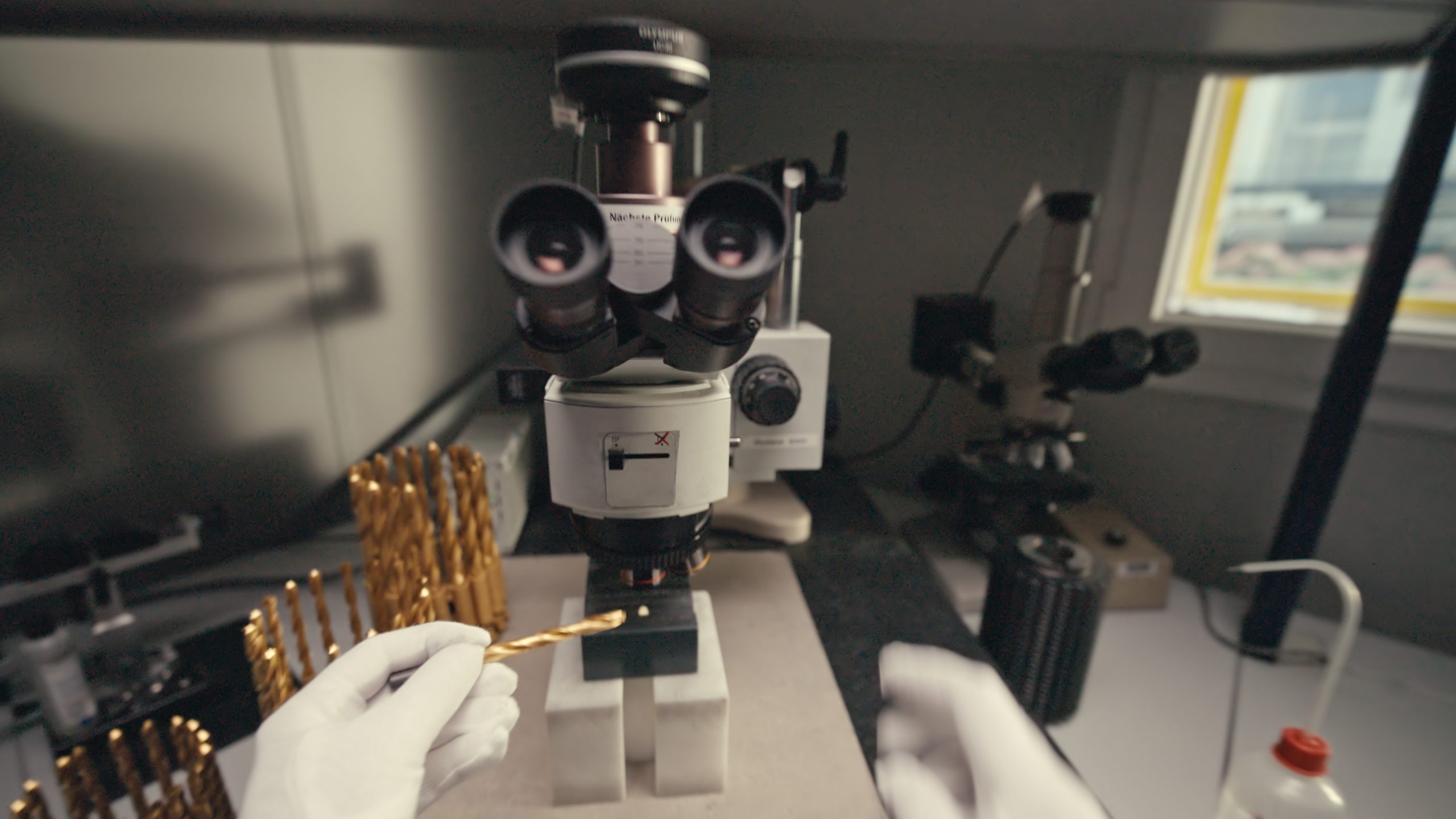

The Ad-Proc-Add II research project conducted by the Institute of Manufacturing Engineering and Photonic Technologies at TU Wien and its research partner FOTEC, in which numerous partners from industry are also involved, focused on optimizing the entire process chain of additive, subtractive, and post-treatment steps in industrial metal 3D printing. The goal: to integrate additive manufacturing into industrial processes. The researchers focused primarily on metallic additive manufacturing in build-up welding, on powder bed processes, and on hirtisation, which is a post-processing technique for the removal of support structures and the smoothing of surfaces.

During ladle purging in secondary metallurgy, liquid steel is homogenized in the ladle to achieve the desired chemical composition, temperature, and purity. An inert gas, such as argon or nitrogen, is introduced through a purge plug and the melt in the ladle is set in motion. This increases the mixing efficiency and homogenization of the melt. Our current development work in Linz and Donawitz (Austria) focuses on the control and classification of this process and thus on how the gas flow can be measured inline. The aim is to further improve steel quality.

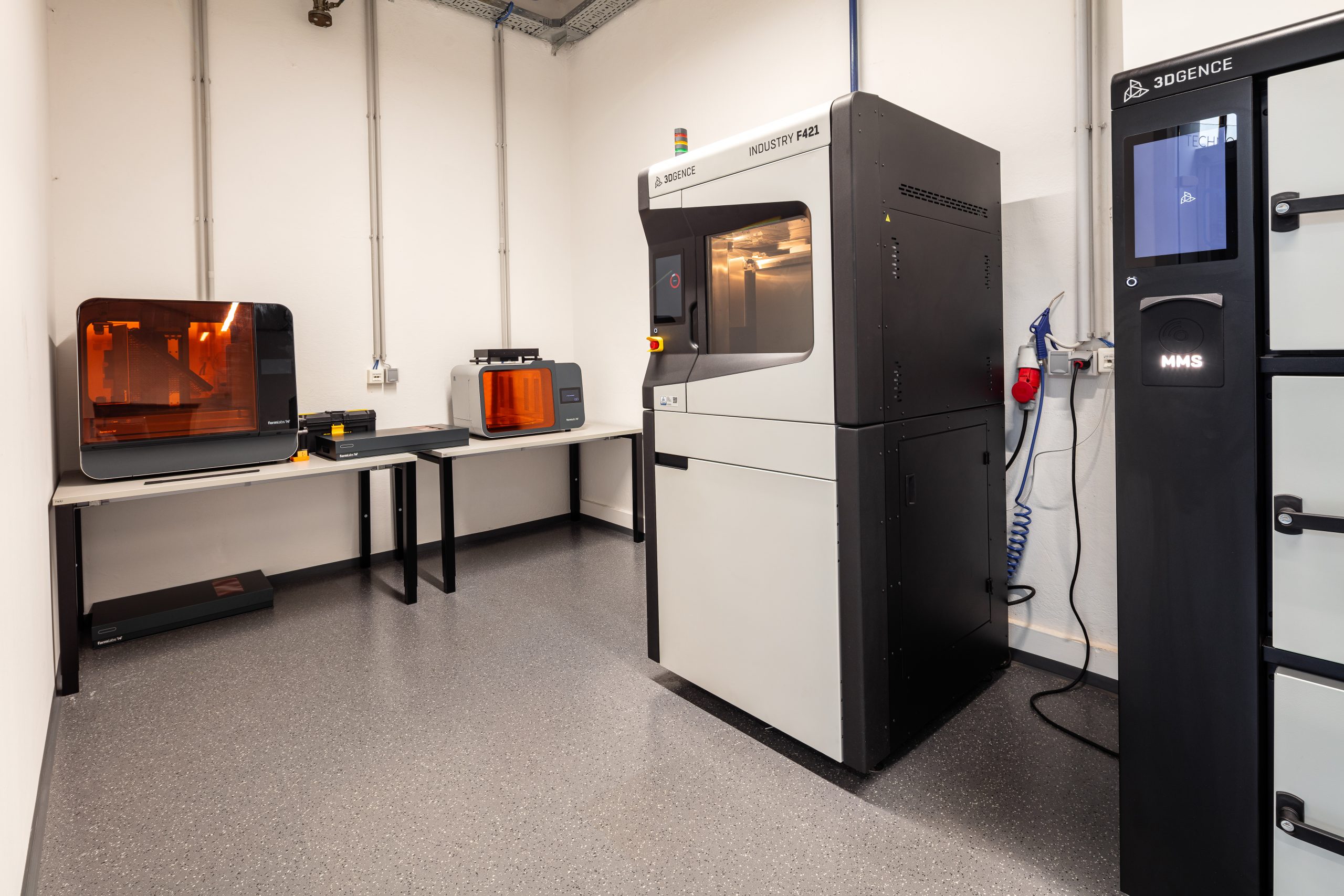

As part of a project in the new business incubator (nbi) of our Steel Division, we examined whether and how a 3D printing competence center could be implemented at the voestalpine site in Linz. The steadily increasing demand, the rapid development of this forward-looking technology, and the desire for professional application confirmed that a “3D printing competence center” makes sense and is necessary! The 3D Printing Competence Center went into regular operation in fall 2025. Three professional devices for filament printing and powder or resin printing for plastic 3D printing are now available there. These printers can be used to manufacture components from a wide range of plastics quickly, safely, and cost-effectively. A professional measurement system for reverse engineering is also available. This means that everything from measurement and design to the finished print of the components can be offered from a single source at the central contact point for 3D printing on site.

Green steel production of the future requires intensive research work in the present. As the examples above show, in addition to our research activities for a clean environment, we are also working on many other innovations, material, product, and process developments – with the clear goal of making our world a little bit better, more beautiful, safer, or more comfortable.

In our new brand and image campaign #FavoriteMoments, we show our contribution to a modern, sustainable life from the perspective of people. We focus on their individual favorite moments and the commitment of our employees that makes such moments possible. The specially composed song “All these moments” accompanies the campaign and musically conveys our values, courage, community and our joy for the future and is authentically accompanied by pictures of our employees.

Die voestalpine ist ein weltweit führender Stahl- und Technologiekonzern mit kombinierter Werkstoff- und Verarbeitungskompetenz. Die global tätige Unternehmensgruppe verfügt über rund 500 Konzerngesellschaften und -standorte in mehr als 50 Ländern auf allen fünf Kontinenten. Sie notiert seit 1995 an der Wiener Börse. Mit ihren Premium-Produkt- und Systemlösungen zählt sie zu den führenden Partnern der Automobil- und Hausgeräteindustrie sowie der Luftfahrt- und Öl- & Gasindustrie und ist darüber hinaus Weltmarktführer bei Bahninfrastruktursystemen, bei Werkzeugstahl und Spezialprofilen. Die voestalpine bekennt sich zu den globalen Klimazielen und verfolgt mit greentec steel einen klaren Plan zur Dekarbonisierung der Stahlproduktion.