H2FUTURE: Research facility generates valuable findings

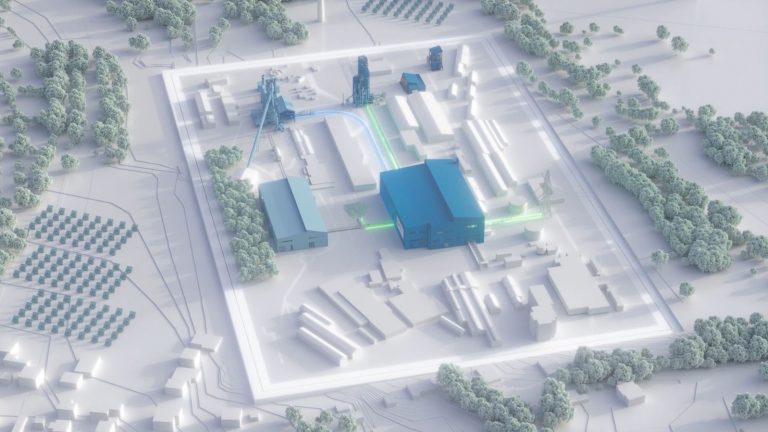

voestalpine’s H2FUTURE project is investigating whether green hydrogen produced on an industrial scale can replace fossil fuels such as coal and coke in steel production over the long term. The electrolysis facility at the plant in Linz is generating important research findings for our future steel production.

- 21 Oct, 2021