About us

voestalpine Wire Technology - PERFORMANCE IN WIRE

voestalpine Wire Technology is one of the leading European manufacturers of wire rod and drawn wire. As a specialist for cold heading wire, flat and shaped wire as well as prestressing steel wire and strands, we offer customized premium solutions for demanding applications - from the automotive supply industry and railroad infrastructure to mechanical engineering, construction and the energy sector.

As part of the voestalpine Group, we combine decades of experience with state-of-the-art technology and a clear focus on quality, innovation, flexibility and sustainability. Our customers benefit from a unique research and development setup, a fully integrated production chain – from raw material extraction to the finished product – and a broad premium product portfolio of over 400 steel alloys.

Our corporate values form the basis for our actions. We live quality, innovation, flexibility and sustainability in every process step - from material development to logistics. Together with our customers, we are shaping the future of wire technology with solutions that are one step ahead. We are the flexible and innovative partner for specific solutions (products, services and logistics) with an extraordinary R&D setup (material and product simulations, MetLab/TechMet, Wire Tech Center).

voestalpine Wire Technology is active worldwide and has strong regional roots. Our international sales structure and long-standing customer relationships enable the reliable supply of premium grades around the globe. Our integrated production chain - from the ore to the finished wire product - guarantees the highest quality, traceability and flexibility.

Innovation is what drives us. With a strong focus on research and development, we set new standards in wire technology. Our experts develop solutions that maximize customer benefits - efficient, precise and future-oriented.

Our processes are based on a certified management system in accordance with

We live a zero-defect philosophy, promote personal responsibility and focus on continuous improvement in all areas.

Sustainability is part of our DNA. We are committed to:

The safety, health and well-being of our employees are at the heart of everything we do. We implement measures that go beyond legal requirements - with a focus on order, cleanliness and prevention.

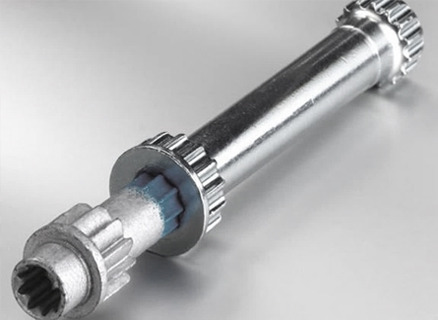

Market leader in complex KFP applications:

Partner for special applications:

Highest quality wire rod and drawn wire for ball and roller bearings

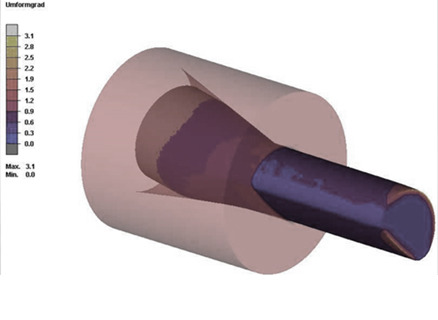

Precision with simulations of cold and warm forming:

Technology leader in wire rod production:

Partnership in the metallurgy association

Discover our philosophy, our product portfolio and our values in detail.

Download our current company brochure here and get a comprehensive insight into voestalpine Wire Technology - compact and clear.

PERFORMANCE IN QUALITY

Our products stand out for their high quality and maximum consistency in mechanical properties, metallurgical structure, geometry, and surface finish.

For us, highest quality means peak performance of our products.

PERFORMANCE IN INNOVATION

With our own R&D setup - including MetLab, TechMet, and the Wire Tech Center - we develop customized wire solutions for new applications and markets - quickly, efficiently, and tailored to customer requirements.

PERFORMANCE IN FLEXIBILITY

Our entire value chain is unique in the industry. Our flexibility in all process steps, from the steel mill to the rolling mill to the workshop drawings, makes us the market leader in wire production.

PERFORMANCE IN SUSTAINABILITY

For us, sustainability is a responsibility - towards the environment, society, and future generations. We integrate ecological principles right from the product development stage.

Progress creates quality and solutions and requires flexibility. Experience and innovation guide us, while technology and sustainability shape our actions.

This image film reflects our identity and plays with the duality of tradition and modernity. Two employees - young and flexible, experienced and innovative - form the PERFORMANCE IN WIRE family and emphasize the importance of shared values for success. Quality, innovation, flexibility, and sustainability can only be achieved together.

Together, we can respond flexibly to new challenges and develop high-quality, innovative, and sustainable wire solutions.

Our integrated process chain enables maximum flexibility - from material development to delivery. With modern logistics concepts and individually tailored packaging solutions, we fulfill complex requirements efficiently and reliably. Long-standing partnerships with customers, suppliers and development partners underline the trust in our quality and innovative strength. Through continuous investment, we remain true to our claim: "One Step Ahead."

Whether you have a specific project inquiry or just want to get in touch - we look forward to hearing from you.