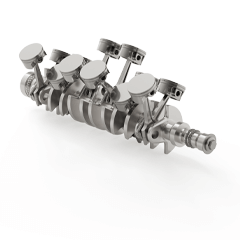

Crankshafts

Steel failures in racing crankshafts are often caused by a harsh combination of mechanical stress, fatigue, and microscopic flaws in the material. Although these components are designed to handle extreme loads, the intense demands of racing engines frequently push them to their limits. The most common material-related failure mechanisms include:

1. Fatigue and Exceeding Material Limits

2. Sudden Overloads and Torque Spikes

To meet these challenges, racing crankshafts are typically made from through-hardened, high-strength steel grades, often enhanced with nitriding treatments. The performance of these alloys can be optimized by refining their chemical composition, improving material cleanliness, and ensuring consistent hardenability—allowing them to deliver reliable strength and durability under the most extreme operating conditions.

Most Common Causes of Material Related Failure

1. Fatigue and Material Limits

- Repeated stress cycles cause fatigue in crankshafts fillets and bearing journals, eventually leading to cracks or catastrophic failure.

- Even high-end materials reach their limits in high-stressed motorsport environments.

Increased cleanliness: most fatigue failures begin at internal inclusions.

Böhler high-performance steels are often remelted using:

- VAR (Vacuum Arc Remelting)

These manufacturing techniques significantly improve the cleanliness of steels including BÖHLER V358 by eliminating oxide & sulphide inclusions which dramatically decrease the fatigue life of components.

2. Overloading and Torque Spikes

- Racing applications require the driveline to transmit very high torque and power, overload conditions which exceed the typical design limits of the crankshaft can occur if steels do not possess sufficient tensile strength.

High tensile strength (≥1300 MPa)

High yield strength (≥1000 MPa)

High fracture toughness, especially in the core

Case Carburising grades

BÖHLER V358 delivers exactly these properties, maintaining a high strength but with sufficient ductility they can withstand sudden overloads.

This grades also deliver an excellent nitriding response allowing designers to further improve the surface hardness of the crankshaft.

BÖHLER V358 VMR, Built for Victory:

- Ultra-Clean Microstructure via VAR eliminates crack-triggering inclusions

- High Tensile Strength (1,320–1,470 MPa) absorbs extreme loads without failure

- Superior Hardenability ensures uniform strength across complex geometry

- Excellent core strength and wear resistance from theChromium-Molybdenum-Vanadium Alloy composition

- Ideal for Nitriding boosts surface hardness for unparalleled fatigue life

To learn more download our OnePager:

Please fill out this contact form for further information.

Fields marked with * are mandatory: