Reducing Scrap Rate

Scrap generation is one of the most critical factors affecting efficiency and cost in high-pressure die casting. This case study is one of many practical examples that show how voestalpine’s expertise in thermal management and die design helps manufacturers reduce scrap and enhance process reliability in high-pressure die casting.

Results at a Glance

SCRAP RATE:

52% improvement (from 8.2% to 3.9%)

a

CLEANING TIME PER SHIFT:

66% improvement (from 21 min to 7 min)

A Case-Based Approach

An aluminium component manufacturer operating in a high-volume environment was experiencing inconsisten casting results.

The production setup involved a cycle time of 73 seconds and a utilization rate of 77%, with variable costs around €0.25 per shot.

The customer was looking to stablize production, improve quality, and reduce losses like re-melting and defective/non-conforming castings. The existing part geometry and casting alloy were to be retained.

The Scenario

HOURLY MACHINE RATE

295 €

CYCLE TIME

73 sec.

SCRAP RATE

8.2 %

VARIABLE COSTS

~ 0.25 € per shot

AVERAGE DEGREE OF UTILIZATION

77 %

CLEANING TIME/SHIFT

21 min.

The die casting process was characterized by a cycle time of 73 seconds and an average machine utilization of 77%, with variable costs of approximately €0.25 per shot. The hourly machine rate was €295, and the scrap rate had reached 8.2%. Cleaning operations required 21 minutes per shift, further reducing productive time and contributing to operational inefficiencies.

The Performance

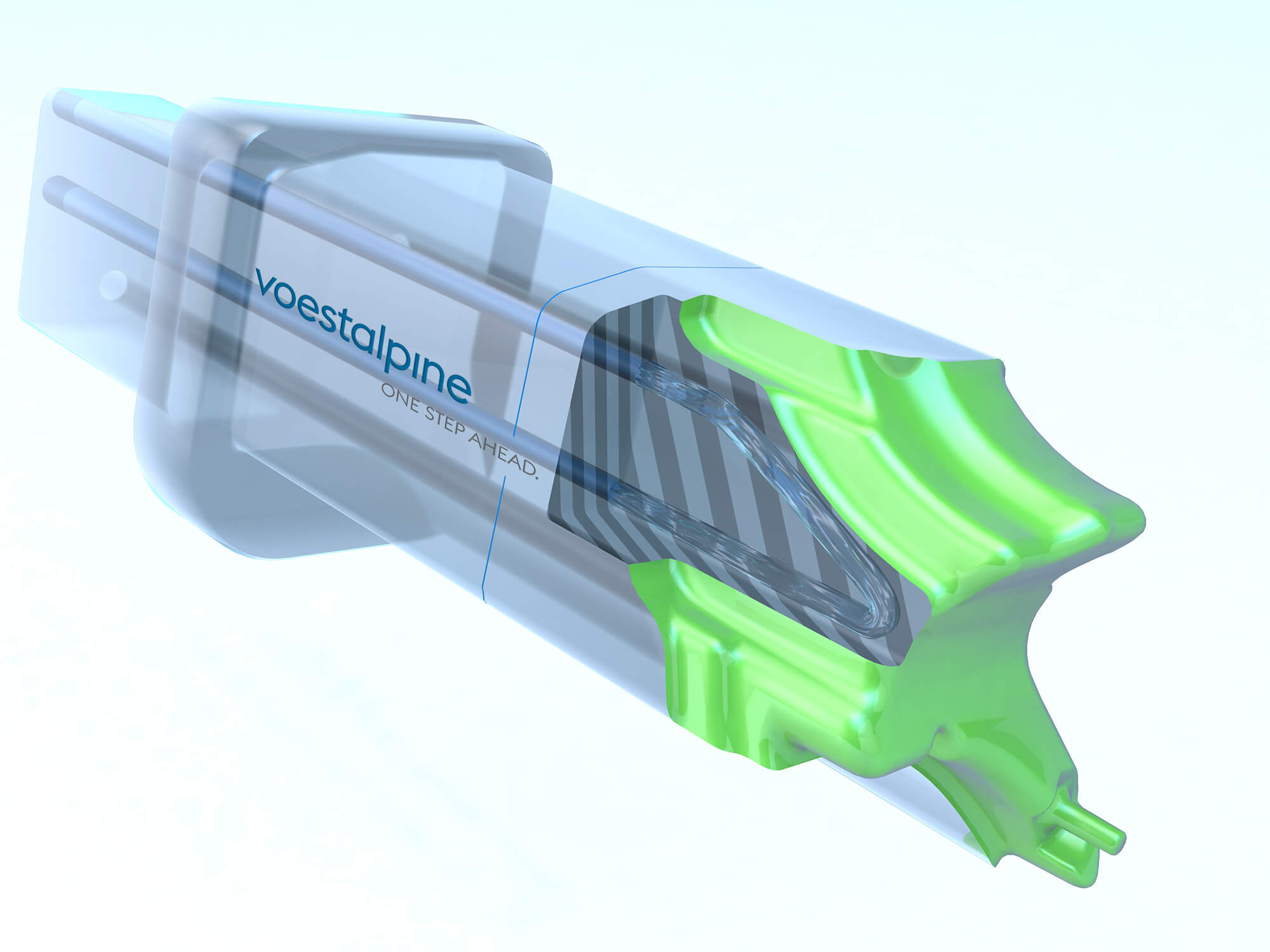

To enhance process stability, voestalpine introduced additively manufactured (AM) inserts featuring conformal cooling channels specifically designed to match the operating conditions of the die casting process. These channels follow the geometry of the die cavity, enabling more efficient and uniform heat removal during each cycle.

This improved thermal management helps prevent localized overheating and supports consistent solidification—resulting in a more stable casting process and fewer non-conforming parts.

COST SAVINGS

166 410 €

AM INVESTMENT

39 020 €

SCRAP RATE

3.9 %

52% improvement

CLEANING SAVINGS

+ 40 500 €

NET SAVINGS

167 890 €

CLEANING TIME/SHIFT

7 min.

66% improvement

As a result, the scrap rate was reduced to 3.9%, and cleaning time per shift decreased to just 7 minutes. These improvements led to total cost savings of €166 410 against an AM investment of €39 020 and included €40 500 saved on cleaning operations. the overall net savings reached €167 890 reflecting a 52% improvement in scrap reduction and a 66% reduction in cleaning time.

This case demonstrates how voestalpine’s engineering expertise and advanced manufacturing technologies can unlock hidden potential in die casting operations—delivering both technical and economic value.

Downloads

Please contact us for more information.

Fields marked with * are mandatory.