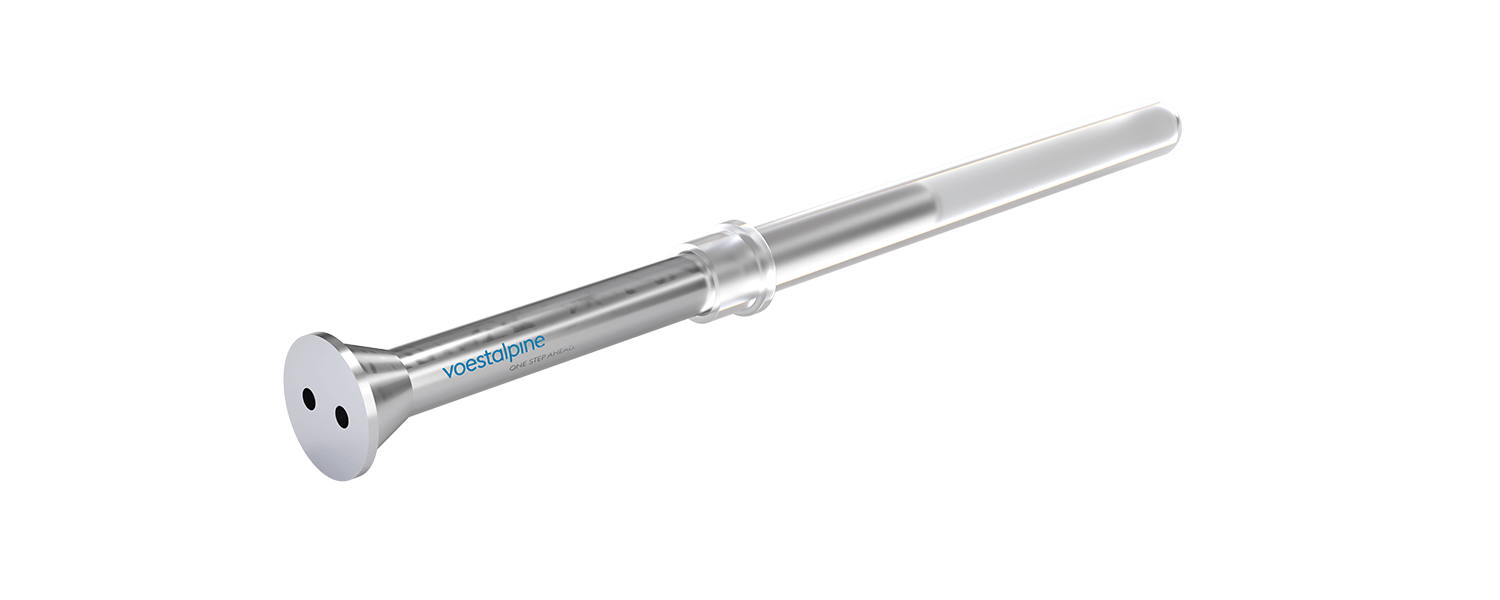

voestalpine Inserts for PET-Preform

designed for pure performance

Our AM Inserts for PET-Preform have optimized conformal cooling solutions, enabling our customers to run a stable and highly efficient production with a minimized cost per plastic part produced.

Our inserts offer higher wear resistance and lifetime compared to standard inserts, resulting in lower costs per plastic part produced. Made using our premium steel, these inserts do not contain copper beryllium, which is a potentially toxic element in standard inserts.

Many PET-preform producers have tested our AM solutions and confirmed the increased profitability by using our corrosion-resistant AM Inserts for PET-Preforms.