voestalpine Chill Blocks

designed for pure performance

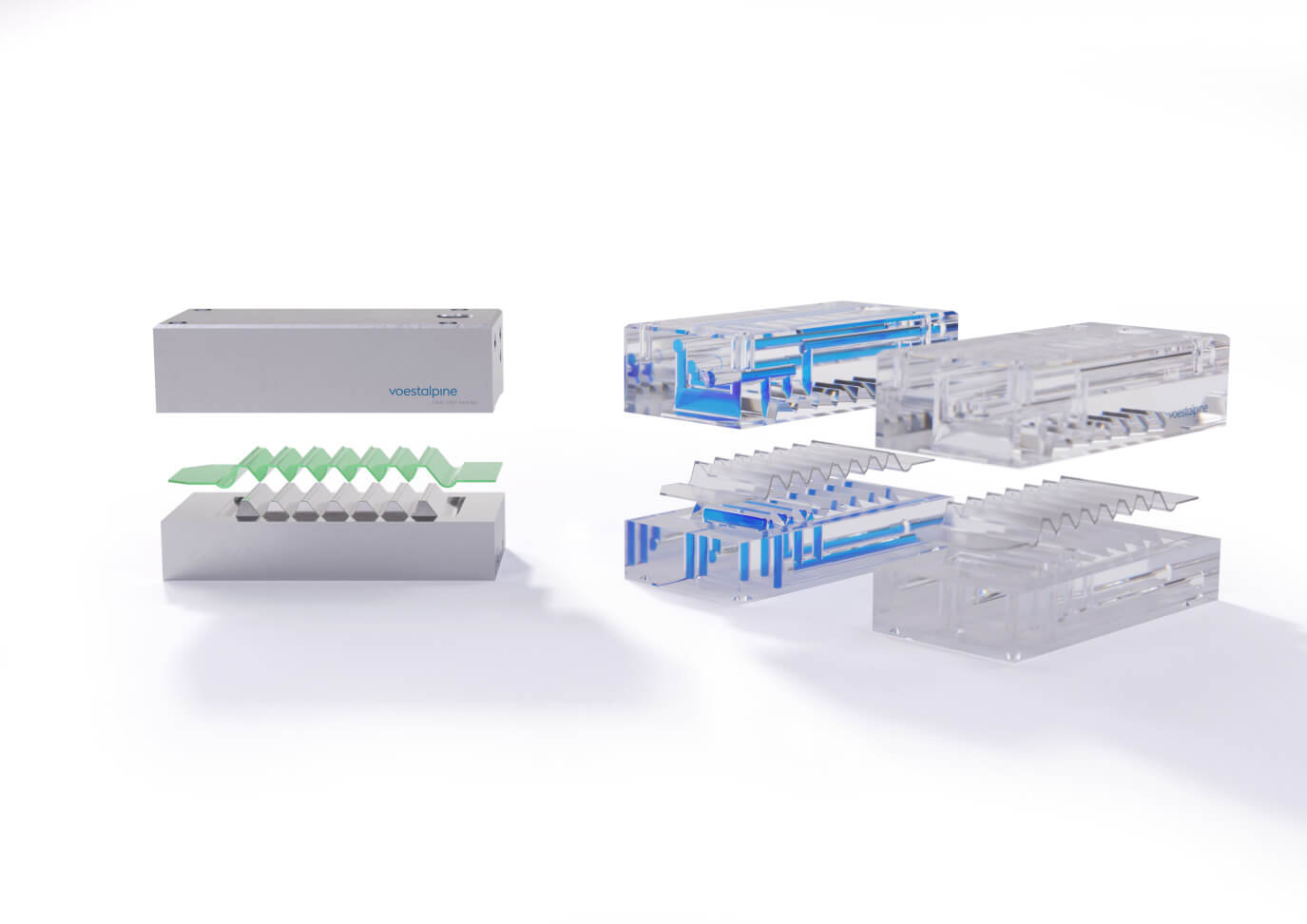

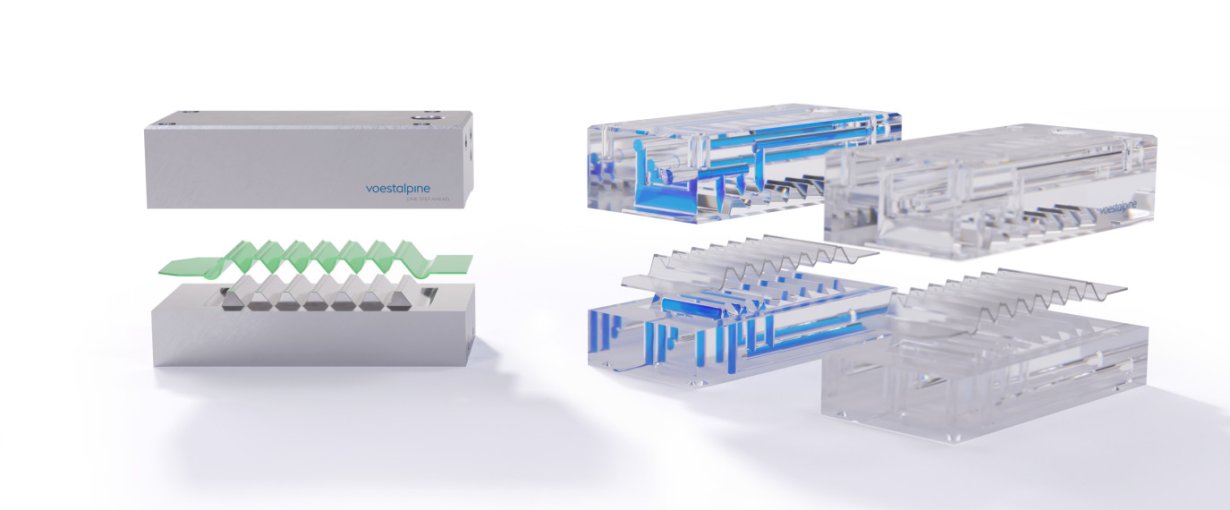

With voestalpine forced venting Chill Blocks, we combine first-class material know-how with our tailor-made solutions for every application requirement. The patented voestalpine wave design allows a large gap size (up to 1.3mm), which enables a consistently high venting performance. During the opening process, the special wave geometry leads to a self-deformation in the forced venting area, thereby lowering the removal forces and providing high process reliability.

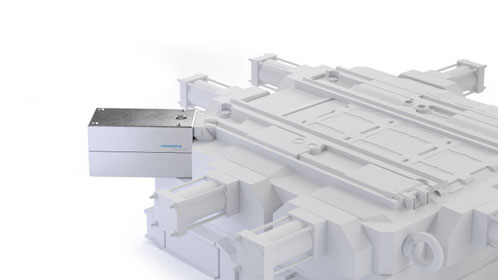

Thanks to its robust steel design, this innovative solution is ideally suited for harsh foundry condition. Furthermore, low downtimes and less maintenance effort increases the OEE for our customers, which leads directly to improved productivity.